For an entrepreneur considering entry into Iran’s solar manufacturing sector, a fundamental question quickly emerges: “Which components for our solar modules can we procure locally?”

This is no mere logistical query; it’s a strategic decision that profoundly impacts project costs, supply chain resilience, and the final product’s quality and bankability. While importing all components might seem like the safest route, this approach overlooks the significant industrial capacity that already exists within Iran. A well-researched local sourcing strategy can offer considerable advantages, from mitigating currency fluctuation risks to reducing transportation costs and import duties.

Drawing on direct experience and supplier audits conducted in the region, this article provides a component-by-component analysis of the local sourcing potential for a solar module’s Bill of Materials (BOM) in Iran. It offers a clear-eyed view of both the opportunities and the essential quality control measures required for success.

The Strategic Importance of the Bill of Materials (BOM)

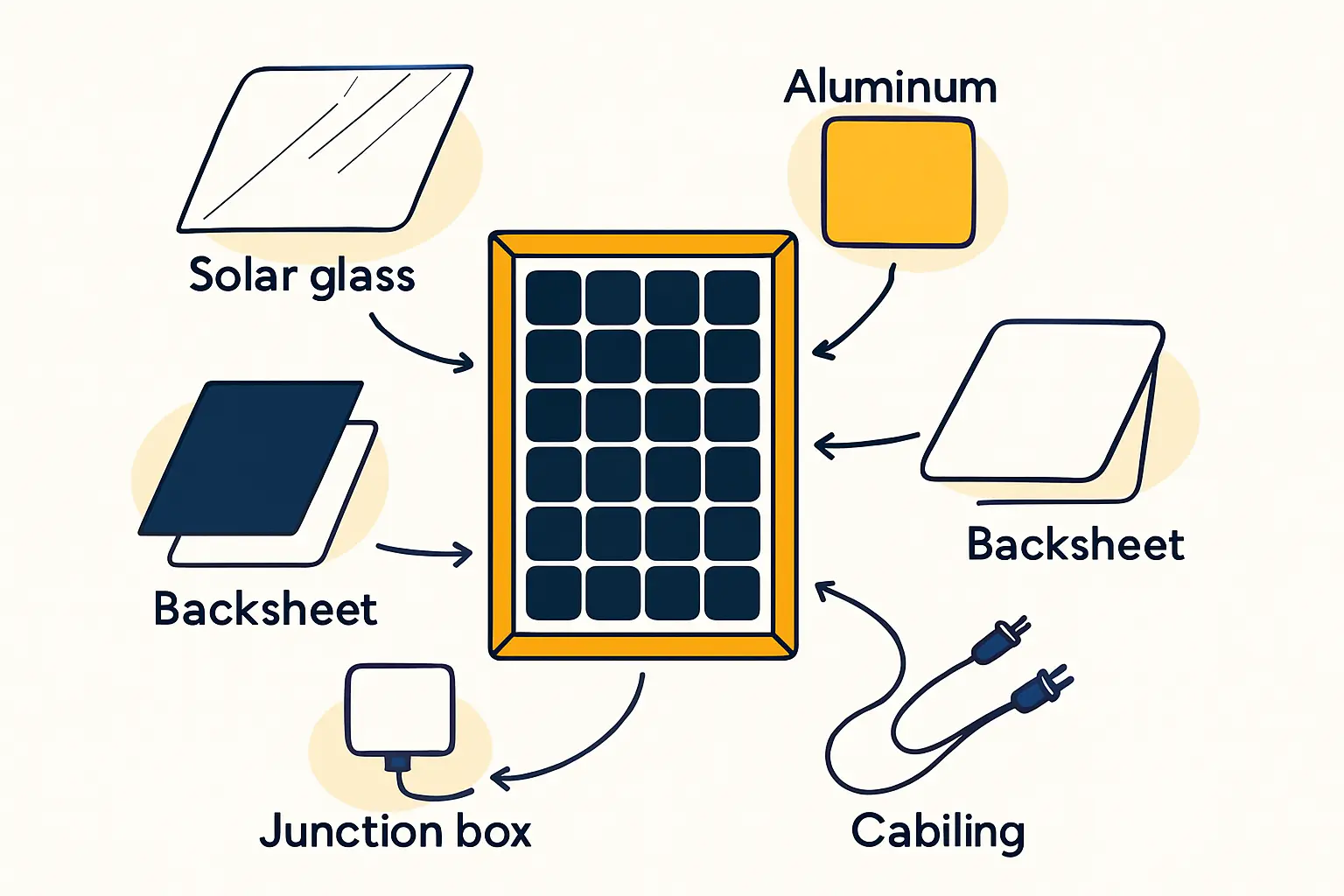

Before diving into individual components, it’s crucial to understand the role of the Bill of Materials. The BOM is the comprehensive list of all raw materials, sub-assemblies, and parts needed to manufacture a final product—in this case, a photovoltaic (PV) module. For anyone planning to start a solar panel production line, mastering the BOM is a fundamental step.

The BOM is more than just a shopping list for your factory; it directly influences:

-

Production Cost: The materials in a BOM typically account for the largest portion of a solar module’s final cost.

-

Product Quality & Reliability: The selection of each component, from the glass to the smallest electrical connector, determines the module’s performance, durability, and lifespan.

-

Bankability: Financial institutions and large-scale project developers will only accept modules built with certified, high-quality components. A poorly sourced BOM can render a product ineligible for major projects.

Understanding the nuances of each material is the first step toward building a robust and cost-effective supply chain.

Analyzing Local Sourcing Potential in Iran: A Component-by-Component Review

Iran possesses a mature industrial base in several key areas relevant to solar manufacturing. Leveraging this capacity, however, requires careful evaluation and a rigorous qualification process. A hybrid approach, combining the best local materials with high-tech imported components, often yields the best results.

Solar Glass: A Strong Foundation with Caveats

Solar glass is a module’s first line of defense, protecting the sensitive solar cells while maximizing light transmission. It is a high-potential candidate for local sourcing in Iran.

Local Availability: Iran has a well-established glass industry, with major players like Kaveh Glass Group producing the patterned, low-iron, tempered glass required for PV applications.

Key Considerations: While the basic product is available, quality is paramount. The critical performance metric is light transmittance; even a small reduction can significantly impact the module’s power output. Other potential issues include physical defects like bubbles, scratches, or dimensional inaccuracies.

Qualification Process: Experience from J.v.G. turnkey projects shows that qualifying a local glass supplier involves a thorough audit. This includes laboratory testing of transmittance values across batches and implementing a strict incoming quality control (IQC) protocol at the factory to inspect every shipment.

Aluminum Frames: Balancing Cost Savings and Precision

The aluminum frame provides structural integrity and serves as the mounting interface for the solar module. Given Iran’s status as a major regional aluminum producer, local sourcing is highly feasible and can yield significant cost savings.

Local Availability: Raw material and extrusion capabilities are readily available across the country.

Key Considerations: The primary challenge lies in precision. Technical drawings for a solar module frame specify tolerances measured in fractions of a millimeter. Deviations in dimensions, hole placements, or the quality of the anodization layer are common issues with non-specialized suppliers.

Qualification Process: Achieving the required precision hinges on providing the local extruder with professional technical drawings. A consultant’s role often includes creating these drawings and assisting in the supplier qualification process. This involves inspecting samples, verifying dimensions with calipers, and testing the anodization thickness to ensure it meets international standards for long-term durability.

Junction Boxes and Connectors: The Critical Link to Reliability

The junction box is the electrical heart of the solar module, housing bypass diodes and providing the connection point for wiring. This, however, is a component where caution is advised.

Local Availability: Some local production of junction boxes exists in Iran, but these are often based on older, simpler designs.

Key Considerations: The most significant hurdle is certification. Internationally recognized certifications from bodies like TÜV or UL are non-negotiable for a bankable module, and local Iranian products rarely carry them. The quality of the plastics, seals, and electrical contacts may also not meet the 25-year service life required of a PV module.

Recommended Strategy: For any manufacturer aiming for a high-quality, export-ready product, importing certified junction boxes and connectors from globally recognized brands is standard practice. The small cost saving from a local component is not worth the immense risk to the module’s safety, reliability, and bankability.

EVA, Backsheet, and Ribbons: The Case for Strategic Imports

Encapsulant (EVA), backsheet, and the tinned copper ribbon used for interconnecting cells are highly specialized, chemically complex materials.

Local Availability: Significant local production of high-quality, certified EVA, backsheet, or multi-busbar-compatible ribbon does not yet exist in Iran. Manufacturing these materials requires advanced chemical engineering and substantial R&D investment.

Key Considerations: These components are critical for the long-term protection of solar cells from moisture, UV radiation, and mechanical stress. A failure in the backsheet or EVA can lead to delamination, moisture ingress, and catastrophic module failure. The ribbon’s quality is also essential for preventing power loss and cell cracking.

Recommended Strategy: These core materials should be imported from reputable international suppliers. They form the technical foundation of the module’s performance and longevity. Compromising on their quality is a false economy, and understanding the complete solar panel bill of materials helps clarify why these specific imports are necessary.

Crafting a Hybrid Sourcing Strategy for Success

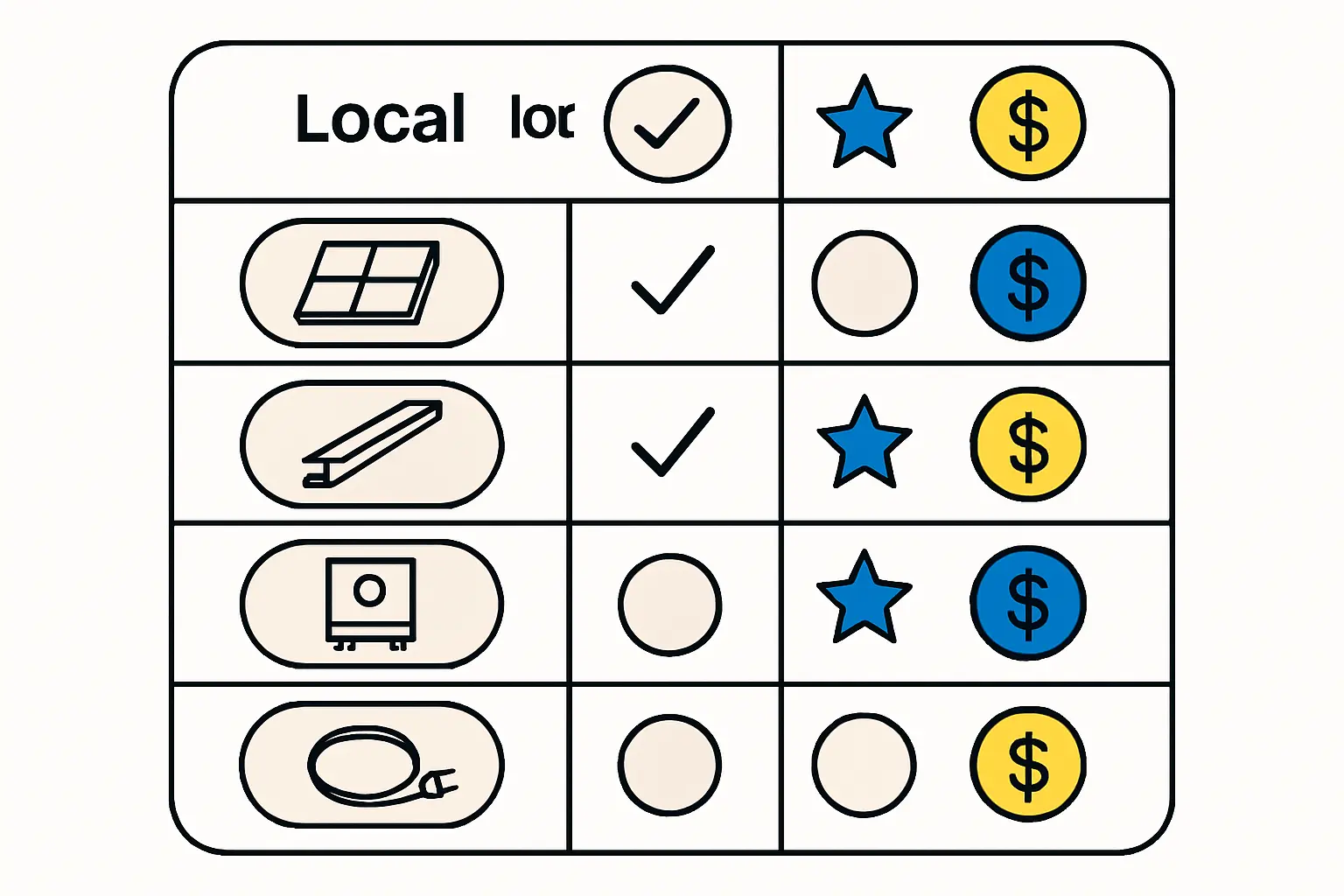

The most pragmatic and effective approach for a new solar module factory in Iran is a hybrid sourcing model. This strategy blends local procurement with strategic imports to optimize for cost, quality, and risk.

A Typical Hybrid BOM for Iran:

Locally Sourced: Solar Glass, Aluminum Frames, Packaging Materials (Cardboard, etc.).

Imported: Solar Cells, EVA, Backsheet, Junction Box, Ribbon, Flux, Labels.

This approach lets a business capitalize on the cost advantages of local glass and frames while using high-quality imported components to guarantee the module’s core performance and reliability. The key to making this work is a steadfast commitment to supplier qualification and quality control—a process that requires technical expertise and on-the-ground diligence.

Frequently Asked Questions (FAQ)

What percentage of a solar panel’s BOM can be sourced locally in Iran?

By value, the most significant components (solar cells) must be imported. However, by weight and volume, key components like glass and aluminum frames can be sourced locally. This can significantly reduce logistics costs and dependence on foreign currency for a portion of the investment requirements.

Are locally sourced components always cheaper?

Initially, the unit price for local glass or aluminum may be lower. However, the total cost must account for quality. If a high percentage of local components fail incoming quality control checks, the ‘effective price’ can increase. A rigorous quality assurance process is essential to realize the potential cost savings.

What are the biggest risks of using unvetted local suppliers?

The primary risks are inconsistent quality and production delays. An unqualified supplier might deliver aluminum frames with incorrect dimensions, halting your entire production line. Similarly, a batch of low-transmittance glass could lead to an entire production run of underperforming modules.

How does using non-certified components affect the final product?

Using non-certified components like junction boxes makes a solar module ‘unbankable.’ This means it will not be approved for use in large-scale solar farms financed by banks or international institutions, severely limiting your product’s market. For any serious manufacturing venture, adherence to international certification standards is mandatory.

The Path Forward: From Sourcing to Production

Developing a supply chain for a solar module manufacturing operation in Iran presents a unique set of opportunities. The country’s industrial strength in glass and aluminum provides a solid foundation for a cost-effective production setup.

Success, however, hinges on navigating the complexities of quality control and supplier management. It requires a clear strategy, precise technical specifications, and an unwavering commitment to international quality standards. By combining local advantages with the best global technology, entrepreneurs can build a resilient and competitive manufacturing business poised to meet the growing demand for solar energy.

چرا شماره تماسی از شما وجود ندارد

Hi, thanks for showing interest in our services. Please send us a message here: https://www.pvknowhow.com/contact/