An investor planning a new solar module factory tends to focus on market demand, logistics, and capital costs. The availability of a water connection is often treated as a simple utility requirement—a box to be checked on a site survey.

In an arid country like Iran, however, this assumption can prove to be a critical and costly vulnerability. For all its environmental benefits, solar panel manufacturing is still an industrial process with its own resource demands, and water is among the most vital.

This article examines the often-underestimated role of water in solar module production. It offers a framework for business professionals to assess water-related risks and opportunities when selecting a factory site in Iran, ensuring that a project designed for long-term sustainability is built on a foundation of resource security.

The Overlooked Input: Why Solar Module Production Requires Water

At first glance, the connection between water and solar panel manufacturing may not be obvious. Yet, water is integral to several key stages of the production process, even in a streamlined module assembly plant.

The quality and efficiency of these precise industrial processes depend heavily on water, which serves three primary functions:

-

Process Cooling: Machines such as laminators and furnaces operate at high temperatures. Water is the most efficient medium for cooling this equipment, preventing overheating and ensuring consistent production quality.

-

Component Cleaning: The single most critical step before lamination is ensuring the solar glass is perfectly clean. Automated glass washing machines use high-pressure jets of purified water to remove dust, grease, or any particles that could compromise module longevity and performance.

-

Facility and Environmental Control: In arid, dusty environments like central Iran, water is essential for dust suppression to maintain a clean production hall. It is also needed for general sanitation and for the building’s climate control (HVAC) systems.

Quantifying the Need: Water Consumption in a Typical Factory

To assess risk, it is crucial to understand the scale of water consumption. Water needs differ greatly between fully vertically integrated manufacturing (from polysilicon to modules) and the more common business model of module assembly. Polysilicon and ingot production are extremely water-intensive, consuming over 12,000 liters per kilowatt-peak (kWp) produced.

For a typical module assembly factory—the focus for most new entrants—the water footprint is considerably lower but still significant. Estimates place water consumption for solar module assembly at 1,000 to 3,500 liters per kWp.

To put this into a business context, a factory with a 50 MW annual capacity could require between 50,000 and 175,000 cubic meters of water per year. While this is a small fraction of the water used by agriculture, securing a reliable supply of this volume in a water-scarce region presents a major challenge and a significant operational risk if not properly planned.

The Iranian Context: Navigating a Water-Stressed Environment

Iran’s geography presents a unique challenge. Over 90% of the country is classified as arid or semi-arid, and its renewable water resources are under severe strain, having declined by nearly 15% in recent years. With agriculture consuming over 90% of the available water, industrial users face increasing competition and regulatory scrutiny.

The Iranian government’s push for solar energy is partly driven by this water crisis, as conventional thermal power plants are massive water consumers. This creates a paradox: building solar factories to help solve the water problem requires a secure water supply for the factories themselves.

Many of the Special Economic Zones (SEZs) promoted for industrial development are located in central provinces like Yazd, Kerman, and Isfahan. While these zones offer logistical and tax advantages, they are also situated in some of the country’s most water-stressed basins. An investor cannot assume that an allocated industrial plot comes with a guaranteed, long-term water supply. Careful due diligence on the source, reliability, and future cost of water is thus a prerequisite for a sustainable investment and directly impacts the factory building and its infrastructure.

Strategic Solutions for Water Management in Solar Manufacturing

Fortunately, technological and planning solutions exist to mitigate water risk. Proactive water management can transform this potential vulnerability into a source of operational resilience and a competitive advantage.

Technology Selection

The choice of solar panel manufacturing machines can dramatically influence a factory’s water consumption.

-

Closed-Loop Water Recycling Systems: These are the most effective solution. By installing an in-house water treatment and recycling system, a factory can reuse over 90% of its process water from cooling and cleaning, cycling it back into use. The initial capital investment is quickly offset by lower water purchasing costs, reduced discharge fees, and insulation from external supply disruptions.

-

Dry Cooling Technology: Instead of traditional water-based cooling towers, air-cooled or “dry” cooling systems can be used for some processes. While these may have a higher initial cost and a larger physical footprint, they virtually eliminate water consumption for cooling.

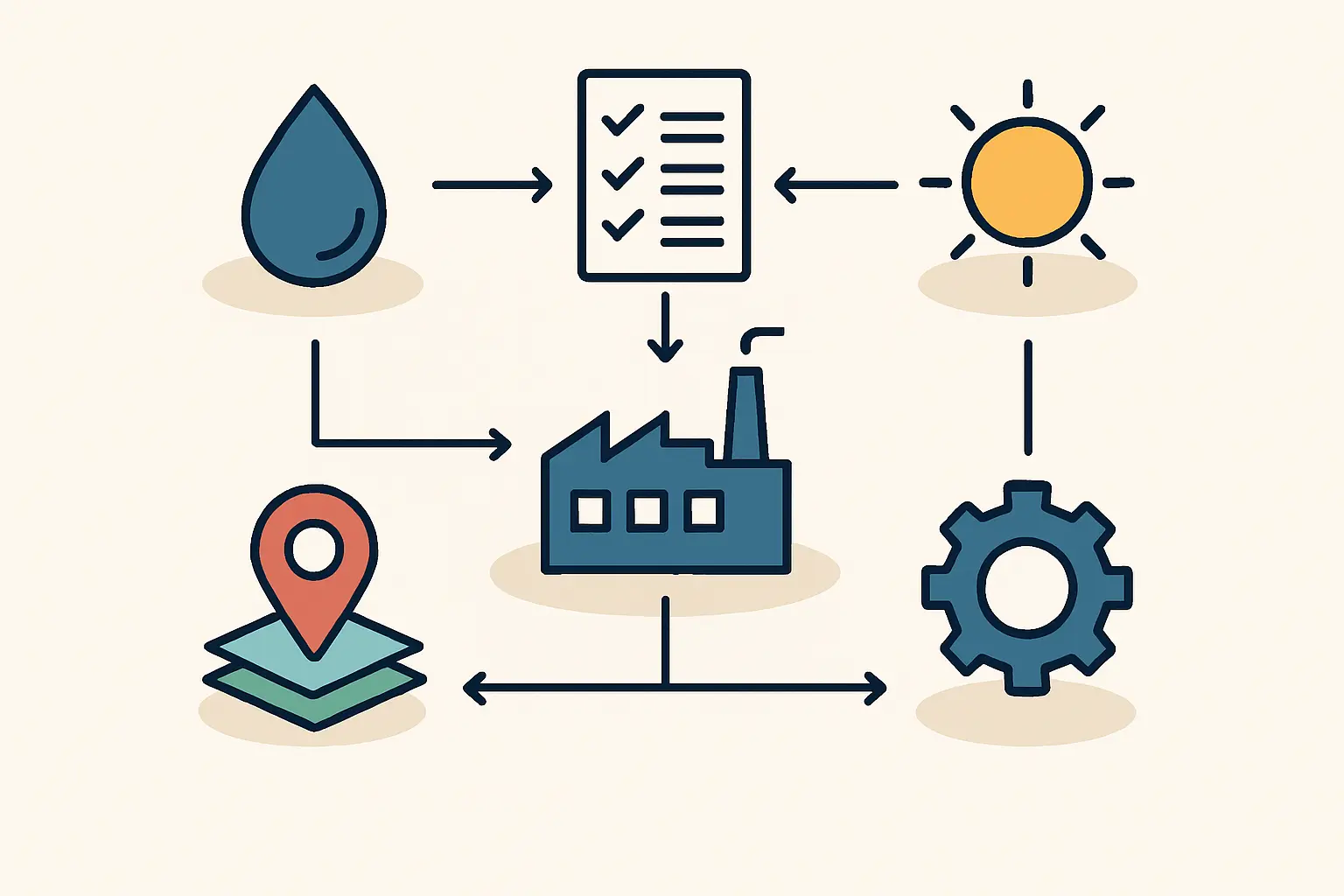

Site Selection Due Diligence

When evaluating potential sites, an investor should look beyond a simple connection point on a map. Key questions to investigate include:

-

Water Source: Is the supply from a municipal network, a dedicated well, or another source? What is the long-term health of that source (for example, local groundwater depletion rates)?

-

Water Quality: The quality of the incoming water—its hardness and mineral content—will determine the level of pre-treatment required, affecting both capital and operational costs.

-

Regulatory Environment: What are the current and projected costs of water? Are there abstraction limits or regulations that could affect the factory in the future? These factors are a crucial input for a comprehensive business plan.

The Broader Perspective: Water as a Core Component of a Sustainable Investment

Addressing water management proactively is not merely a technical task; it is a fundamental part of building a bankable and resilient business. A factory that demonstrates efficient water use is less exposed to regulatory risk, volatile utility costs, and potential production stoppages. Based on experience from J.v.G. turnkey projects, incorporating water infrastructure planning from the earliest stages prevents costly retrofits and operational bottlenecks down the line.

Ultimately, a well-planned facility that respects local resource constraints is more likely to gain community support and position itself as a responsible long-term partner in the region’s development. This strategic approach is central to planning a successful turnkey solar module production line.

Frequently Asked Questions (FAQ)

Q1: Is water scarcity a deal-breaker for setting up a solar factory in an arid region like Iran?

No, it is not a deal-breaker. It does, however, require that water management be treated as a core strategic element of the project plan, with dedicated investment in water-efficient technologies like closed-loop recycling systems.

Q2: How much does a water recycling system add to the initial investment?

The cost of a water recycling system is a small fraction of the total project investment, typically representing just 1-3% of the overall capital expenditure for the production line. This initial cost provides a strong return by significantly lowering long-term operational expenses and mitigating supply risks.

Q3: Does the type of solar module (e.g., PERC, TOPCon) significantly change water consumption during assembly?

For the module assembly stage, the specific cell technology does not significantly alter water consumption. The primary uses—glass washing and process cooling—are common to virtually all crystalline silicon module manufacturing lines. The main differences in water footprint occur much earlier in the value chain, such as during wafer manufacturing.

Q4: Can a factory use seawater or brackish water?

Yes, this is technically possible but adds another layer of complexity and cost. Using such sources would require an on-site desalination plant (e.g., using reverse osmosis), which has significant capital, energy, and maintenance costs that must be carefully modeled in the project’s financial projections.

Conclusion: Planning for Resilience

For any entrepreneur or investor looking to enter the solar manufacturing sector in Iran, water is not a footnote in the site selection process—it is a headline. The arid climate and national water stress demand a strategic approach that moves beyond securing a simple connection to ensuring long-term resource security.

By integrating water-efficient technologies and conducting thorough due diligence from the outset, a potential liability can be transformed into a source of strength. A factory designed for water resilience is not only more environmentally responsible but is also a more secure, predictable, and ultimately more profitable long-term investment.