Imagine a critical phase in the solar module manufacturing process: the lamination cycle. Multiple layers of material are fusing under precise heat and pressure. Halfway through the 20-minute cycle, the lights flicker, and the entire production line grinds to a halt. This is not just a minor inconvenience—it’s a failure that can destroy an entire batch of modules, representing a significant financial loss. For industrial operators in regions with developing or strained power infrastructure, this is a daily risk.

This article explores the critical importance of grid stability analysis when planning a solar module factory, specifically within the operational landscape of Iraq. It outlines how to engineer a power solution that ensures 100% production uptime, transforming a major liability into a controlled asset.

The Reality of Iraq’s Electrical Grid for Industrial Users

Understanding the local context is the first step in responsible project planning. Iraq’s national electricity grid faces considerable challenges. Current estimates place peak summer demand at approximately 34 gigawatts (GW), while available generation capacity often hovers around 24 GW. This fundamental deficit, worsened by significant transmission and distribution losses, leads to frequent and often unpredictable power outages nationwide.

For a business professional, these figures translate directly into quantifiable risk. Relying solely on the public grid for a high-technology manufacturing facility is not a viable strategy. Industrial consumers often depend on private diesel generators to bridge the gap, but this approach has its own challenges, including high fuel costs, logistical complexities, and constant maintenance. A successful manufacturing venture requires a more robust and integrated solution.

Why Uninterrupted Power is Crucial for Solar Module Manufacturing

A solar module factory operates more like a laboratory than a traditional workshop. Several core processes are exceptionally sensitive to power fluctuations, and even a momentary interruption can have cascading consequences.

-

Lamination and Curing: This process requires a sustained, uninterrupted cycle at a specific temperature profile to properly cure the encapsulant material. A power failure mid-cycle can cause delamination, bubbles, or improper adhesion, rendering the entire batch of modules worthless.

-

Stringing and Tabbing: Modern, automated solar panel manufacturing machines use precision robotics to solder delicate solar cells together. An abrupt shutdown can damage the equipment and break expensive cells, halting production for hours.

-

Climate and Cleanliness Control: The entire production hall must be maintained under strict temperature, humidity, and dust-controlled conditions. A loss of power to the HVAC and filtration systems can compromise the entire production environment and lead to quality defects.

These technical vulnerabilities directly impact the bottom line through wasted materials, equipment damage, costly downtime, and a failure to meet production targets defined in the business plan for a solar panel factory.

Engineering a Resilient Power Solution: Key Components

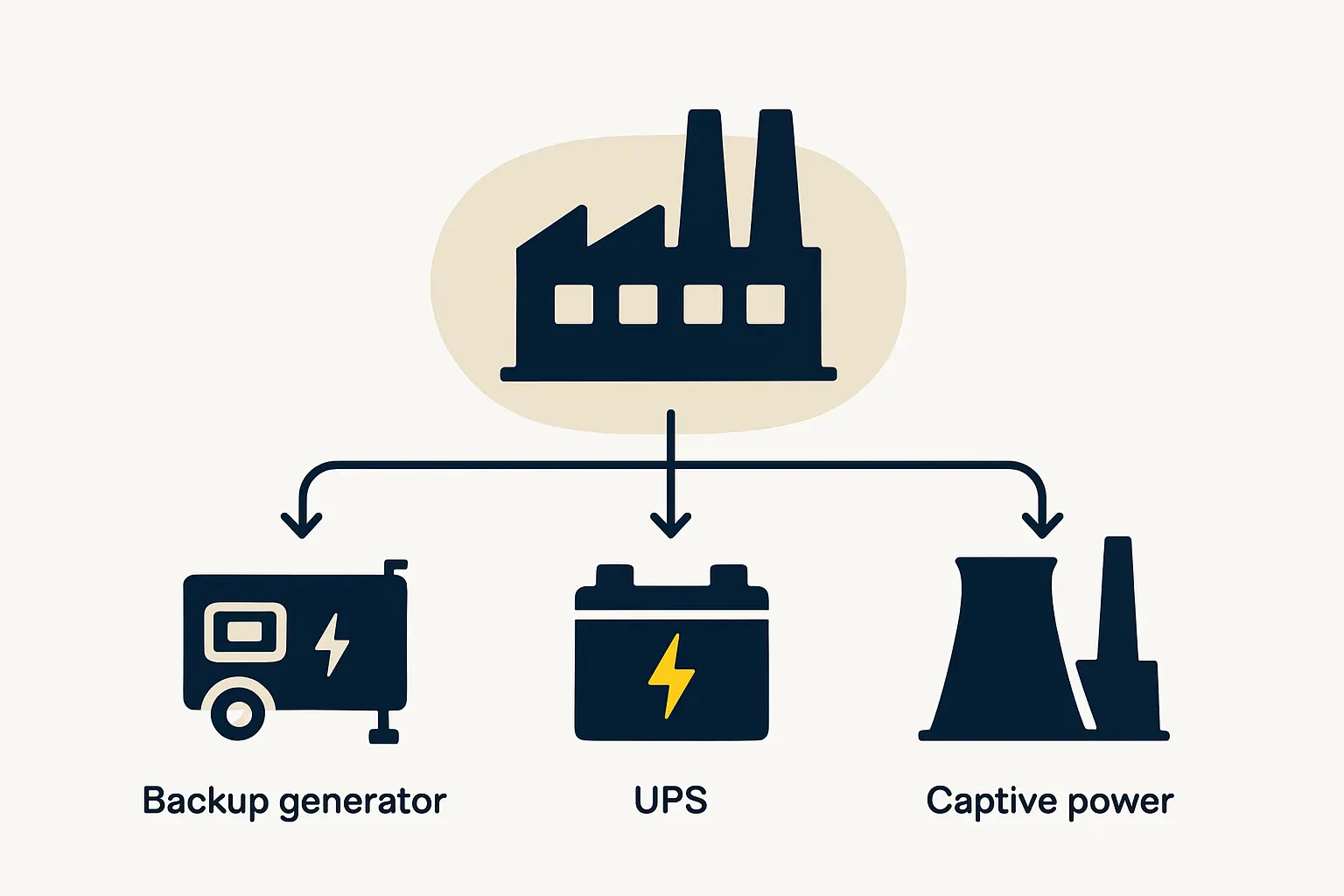

To achieve complete energy independence and ensure continuous operation, a factory needs its own captive power system. This usually takes the form of a hybrid model, combining several energy sources for maximum reliability and cost-effectiveness.

The Role of Backup Generators

The diesel or natural gas generator is the foundation of any reliable backup power system. It serves as the ultimate safeguard, able to run the entire factory for extended periods during prolonged grid outages. Sizing the generator is a critical technical task. It must be powerful enough to handle the factory’s total electrical load and manage the high “inrush current” that occurs when large motors start simultaneously. Proper planning for fuel storage and supply logistics is an equally important operational consideration.

Integrating Solar PV as a Primary Source

For a solar module factory, generating its own clean power with a rooftop solar installation is a logical and economically sound decision. In a high-irradiation environment like Iraq, a properly sized photovoltaic (PV) system can supply a large portion of the factory’s daytime energy needs. This directly reduces operating costs by displacing expensive fuel for the generator or electricity from an unreliable grid. However, because solar power is intermittent by nature—available only during daylight hours—it must be part of a larger, integrated solution.

The Critical Link: Battery Energy Storage Systems (BESS)

A Battery Energy Storage System is the component that elevates a simple backup system into a seamless, uninterrupted power supply. The BESS serves two primary functions:

-

Energy Shifting: It stores excess solar energy generated during the day for use at night or during overcast weather.

-

Instantaneous Backup: When the grid fails, the BESS can deliver power to the entire facility instantly, with zero delay. This bridges the critical seconds or minutes it takes for the backup generator to start up and synchronize, ensuring that sensitive machinery never experiences an interruption.

The Hybrid Power Model in Practice

These three components—generator, solar PV, and battery storage—work in concert, governed by an intelligent energy management system. This creates a resilient microgrid tailored to the factory’s needs.

A typical operational sequence shows the system’s value:

-

Grid Available (Day): The factory runs primarily on its own solar power, with any excess energy charging the batteries.

-

Grid Available (Night): The factory draws power from the charged batteries first, switching to the grid only if they are depleted.

-

Grid Failure (Day): The system seamlessly continues to run on solar and battery power. Production is not interrupted.

-

Grid Failure (Night/Extended): The batteries provide instant power. The system automatically signals the generator to start, which then takes over the load for as long as needed.

Experience from J.v.G. Technology turnkey projects in regions with similar grid challenges shows that a detailed power audit and hybrid system design are among the first essential steps. This analysis often reveals long-term operational savings that far outweigh the initial capital investment in the captive power infrastructure.

Planning and Investment Considerations

A robust captive power system is not an accessory; it is a core piece of infrastructure. Its design and specifications must be integrated into the initial factory building requirements and financial models.

The investment in generators, solar arrays, and batteries can be substantial—for a 20-50 MW factory, a backup system may require a capacity of 500 kVA to over 1 MVA. However, this cost should be viewed as an insurance policy against catastrophic production losses. The return on this investment comes from predictable output, minimal waste, and uninterrupted operations, regardless of external grid conditions.

Frequently Asked Questions (FAQ)

Q1: Can a solar factory run entirely on its own solar power?

A: While a solar PV system can cover much of the daytime energy demand, achieving 100% reliability for 24/7 manufacturing requires a hybrid system. This includes battery storage for nighttime operation and a backup generator to cover extended periods of low sunlight or to handle peak loads.

Q2: How large does the backup generator need to be?

A: The generator must be sized based on a detailed analysis of the factory’s total potential electrical load. This includes the simultaneous power consumption of all your solar panel manufacturing machines, lighting, HVAC, and office equipment, with special consideration for the high starting currents of large motors.

Q3: Is a battery system always necessary if we have a generator?

A: For manufacturing processes sensitive to even a momentary power loss, a battery system is essential. It acts as an uninterruptible power supply (UPS), ensuring a seamless transition during an outage while the generator starts. Without it, a brief but critical power gap will occur.

Q4: How does this power system affect the overall project budget?

A: A captive hybrid power system represents a significant capital expenditure and must be included in the initial business plan for a solar panel factory. It is essential infrastructure, comparable to the building itself, and is fundamental to the plant’s long-term profitability and operational stability.

In a market with the industrial potential of Iraq, planning for energy independence is not an optional upgrade; it is a prerequisite for success. A well-designed hybrid power system transforms an unpredictable external variable—the public grid—into a controlled, reliable, and cost-optimized internal asset, laying the foundation for a resilient and profitable solar manufacturing operation.