An entrepreneur presents a comprehensive business plan for a new solar module factory near Basra. The financial projections are sound, market demand is clear, and the technology is proven. Yet, during the board presentation, the first question is not about return on investment but about risk: “How can we guarantee the safety of our assets and personnel in Iraq?”

This question highlights a critical reality. In complex environments, security and logistical planning are not secondary considerations; they are the very foundation of a successful enterprise.

This guide provides a professional framework for understanding and mitigating the key security and logistical risks of establishing and operating a manufacturing plant in Iraq. It is written for business leaders who are technically curious but not security experts, offering a structured approach to a subject that can often seem overwhelming.

Understanding the Operational Landscape in Iraq

Operating in Iraq offers immense opportunities alongside significant challenges. The country has a substantial demand for infrastructure, energy, and locally manufactured goods, but realizing this potential requires a clear-eyed assessment of the operational landscape. Risks can be broadly categorized into security, logistics, and operations.

According to global risk management consultancies, the security environment varies dramatically between regions like the Kurdistan Region, the central provinces around Baghdad, and southern economic hubs like Basra. A one-size-fits-all security plan is therefore bound to fail. A successful strategy must be tailored to the specific location, supply routes, and nature of the business.

Key risks to consider include:

Security: Theft of raw materials or finished goods, sabotage, and regional instability that can impact transport.

Logistics: Congestion at key ports like Umm Qasr, unpredictable customs clearance, and variable road infrastructure.

Operations: An inconsistent power supply from the national grid, requiring robust on-site generation, and the need for specialized workforce training.

A Framework for Facility Security Planning

A secure facility is the core of any manufacturing operation. Planning must begin long before breaking ground, as early decisions have long-term consequences. A methodical, layered approach to security is the most effective.

1. Site Selection and Hardening

The first and most critical decision is the plant’s location. Whenever possible, select a site within a designated and secured industrial or free zone. These areas often provide baseline infrastructure and a coordinated security presence, reducing the burden on an individual company.

Once a site is chosen, physical hardening is the next priority. This involves creating concentric rings of protection:

-

Perimeter Security: High-quality fencing, clear zones free of obstructions, and strategically placed lighting.

-

Access Control: A single, well-guarded entry and exit point for all vehicles and personnel, with facilities for thorough vehicle inspections.

-

Building Fortification: Reinforcement of critical structures and control rooms.

-

Surveillance: A comprehensive network of CCTV cameras covering the perimeter, access points, and high-value areas like warehouses and production floors.

This investment is not merely an expense; it is a critical part of protecting the core business. A detailed examination of these elements is a fundamental part of any factory design.

2. Access Control and Personnel Vetting

Even the most sophisticated physical barriers can be undermined by internal threats. A strict access control protocol is essential, with different clearance levels for employees, contractors, and visitors to ensure individuals only enter areas required for their work.

Thorough vetting of all personnel, conducted by a reputable local partner, is a standard procedure that builds a trusted workforce and mitigates internal risks. For instance, experience from J.v.G. turnkey projects in similar markets shows that establishing a clear protocol for delivery vehicles—requiring them to check in at a secure gate before proceeding to loading bays—dramatically reduces opportunities for theft.

3. Local Engagement and Intelligence

Technology and physical barriers are only part of the solution. Building strong, positive relationships with local community leaders, tribal elders, and official security forces is invaluable. This engagement provides a level of “ground truth” and early warning that no surveillance system can match. A factory seen as a positive local employer and community partner is inherently more secure.

Securing the Supply Chain: From Port to Plant

A factory cannot operate without a secure supply chain for both raw materials and finished products. The security of this chain is as important as the security of the plant itself.

1. Route and Transport Security

Every transport route, particularly from major entry points like the port of Umm Qasr to the factory, must undergo a professional risk assessment. This involves identifying potential chokepoints, areas of instability, and safe havens.

Key measures include:

-

Vetted Logistics Partners: Working exclusively with established, trusted local transport companies that have a proven track record.

-

Convoy Procedures: Using lead and follow vehicles for high-value shipments when necessary.

-

GPS Tracking: Real-time monitoring of all vehicles carrying valuable cargo.

-

Contingency Routes: Pre-planning alternative routes in case the primary one becomes compromised.

The initial setup phase, when high-value manufacturing equipment and raw materials are moved and installed, represents a period of heightened risk and requires particularly meticulous logistical planning.

2. Inventory Management and Warehousing

Given the potential for logistical delays at ports or on roads, a “just-in-time” inventory strategy is often inappropriate. It is prudent to maintain a larger-than-normal buffer stock of critical raw materials on-site. While this adds to the initial capital outlay, it provides crucial resilience against supply chain disruptions and ensures production can continue uninterrupted. The on-site warehouse must be one of the most secure zones within the facility.

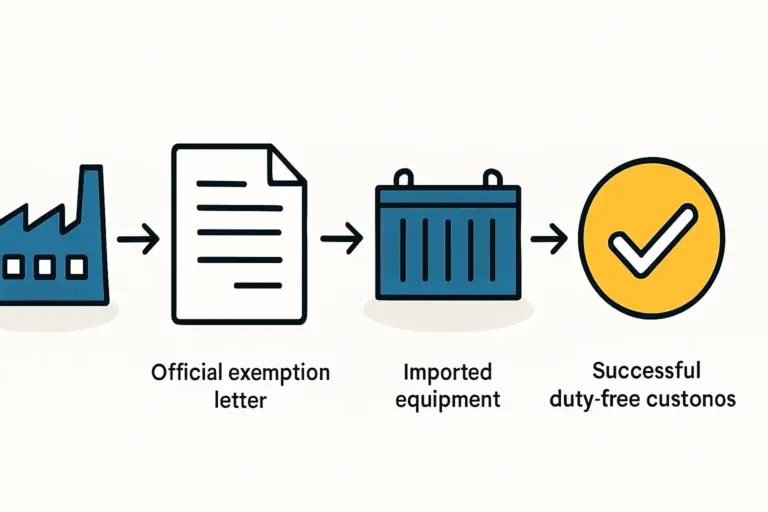

3. Customs and Administrative Planning

Delays in customs clearance are a common logistical challenge. Experience from numerous J.v.G. projects shows that engaging a reputable local customs broker is one of the most effective ways to mitigate this risk. These partners understand local procedures and documentation requirements, helping to ensure that shipments are cleared efficiently and predictably.

Personnel Safety and Training

A company’s ultimate responsibility is the safety of its people, including local employees and any expatriate technical staff or management.

A comprehensive personnel safety plan should include:

-

Secure Transport: Providing secure, reliable transportation for key personnel between their accommodation and the factory.

-

Secure Accommodation: Ensuring that housing for expatriate staff meets high security standards.

-

Regular Training: Conducting regular drills and briefings on emergency procedures, evacuation plans, and communication protocols.

-

Cultural Sensitivity: Developing and implementing all security protocols with respect for local culture and norms is essential for gaining the cooperation of the local workforce.

Frequently Asked Questions (FAQ)

Is it truly feasible to operate a secure manufacturing facility in Iraq?

Yes. Numerous local and international companies are doing it successfully. The key is not to underestimate the challenges but to address them with professional planning, sufficient investment in security, and the engagement of experienced local partners.

What is a typical budget for security as a percentage of operational costs?

This can vary significantly depending on the location, the value of the goods, and the assessed risk level. However, a business plan should realistically allocate between 5% and 15% of its annual operational expenditure (OPEX) to comprehensive security measures.

Should a company hire an international security firm or a local one?

A hybrid approach is often most effective. An international advisory firm can help establish global best-practice standards and governance, while a vetted local security provider handles on-the-ground implementation. The local partner’s intelligence and community integration are indispensable.

How does the security situation in the Kurdistan Region compare to the rest of Iraq?

Historically, the Kurdistan Region of Iraq (KRI) has maintained a more stable security environment than the federal provinces, making it a preferred entry point for many international businesses. However, a thorough risk assessment is still required for any specific location within the KRI.

Conclusion: Integrating Security into Your Business Plan

For any entrepreneur or investor considering a manufacturing project in Iraq, security and logistics cannot be an afterthought. They must be woven into the core business plan from day one. A detailed security and logistics plan is as fundamental as the financial model or the marketing strategy.

While the complexities are significant, they are manageable with a structured, expert-guided approach. Addressing these risks head-on with meticulous planning and the right local expertise is what separates a speculative venture from a resilient, long-term investment.

The most critical step is this initial phase, including a detailed feasibility study and risk assessment. To help frame these crucial questions at the very beginning of your planning process, structured educational resources like the free e-course on pvknowhow.com can provide an essential starting point.