The Italian government has committed over one billion euros to developing its agrivoltaics sector, creating a substantial, highly specific opportunity for solar module manufacturers. This isn’t a market for standard, off-the-shelf panels.

Success hinges on producing specialized modules tailored to the unique demands of dual-use land—where agriculture and energy production coexist. For entrepreneurs entering the solar industry, understanding these requirements is the first step toward tapping into this state-supported initiative.

This article outlines the technical specifications for agrivoltaic modules in Italy and details how to configure a production line to manufacture them. It serves as a blueprint for investors and business leaders looking to establish a factory that serves this growing, high-value niche.

The Financial and Regulatory Landscape in Italy

To understand the manufacturing requirements, it is essential to first appreciate what is driving the market. Italy’s National Recovery and Resilience Plan (PNRR) has allocated €1.1 billion specifically for advanced agrivoltaic systems, with the goal of installing 1.04 GW of new capacity by June 2026.

The program offers two compelling financial incentives for project developers:

- Capital Grants: Covering up to 40% of eligible investment costs.

- Feed-in Tariffs: Providing long-term, stable revenue for the energy produced.

However, to qualify for these incentives, the solar modules themselves must meet strict technical criteria defined by the government. This creates a protected market for manufacturers who can supply compliant products.

What Makes a Solar Module “Agrivoltaic-Ready”?

The Italian decree clearly outlines the required technical characteristics. These rules are designed to ensure that agricultural activity remains viable beneath the panels, transforming a simple solar farm into a true agrivoltaic system.

Elevation and Land Use Regulations

A key requirement governs the physical placement of the modules. They must be installed at a minimum height to permit farming activities below:

- 1.3 meters for horticultural and low-lying crops.

- 2.1 meters for arable crops, allowing passage for modern farming machinery.

The ground coverage ratio (GCR)—the percentage of land covered by the modules—cannot exceed 40%, ensuring sufficient sunlight reaches the crops. For a module manufacturer, these structural requirements mean the panels must be exceptionally durable to withstand higher wind loads and offer maximum efficiency within a limited surface area.

The Mandate for Bifacial Technology

The most significant technical specification is the requirement for bifacial modules. Unlike standard monofacial panels that capture sunlight only on their front side, bifacial modules have active solar cells on both sides.

This design captures direct sunlight from above and reflected sunlight (known as “albedo”) from the ground and crops below. In an elevated agrivoltaic setup, this dual-capture capability can increase total energy yield by 5% to 20%, depending on the reflectivity of the surface beneath.

This performance boost is critical for the economic viability of agrivoltaic projects, making bifacial technology non-negotiable for this market.

Choosing the Right Module Construction: The Case for Glass-Glass

Bifacial cells require a specific module construction to function effectively and reliably over a 30-year lifespan. While standard panels often use a glass front and a polymer backsheet (Glass-Foil), the superior choice for bifacial applications is a Glass-Glass (G-G) construction.

A Glass-Glass module sandwiches the solar cells between two layers of heat-strengthened glass. This design offers several distinct advantages for agrivoltaics:

- Enhanced Durability: The rear glass provides robust protection against moisture, humidity, and mechanical stress. This is crucial in an agricultural environment where panels are exposed to ammonia, pesticides, and the physical impacts of farming.

- Optimal Bifacial Performance: The transparent rear glass allows reflected light to reach the back side of the solar cells without obstruction, maximizing energy generation.

- Increased Longevity: Glass-Glass modules exhibit lower annual power degradation compared to their Glass-Foil counterparts, ensuring a more reliable energy output over the project’s lifetime—a key consideration for investors seeking long-term returns.

As European markets increasingly shift toward high-performance, application-specific modules, building a factory capable of producing Glass-Glass products positions a new manufacturer for future growth beyond the Italian agrivoltaics niche.

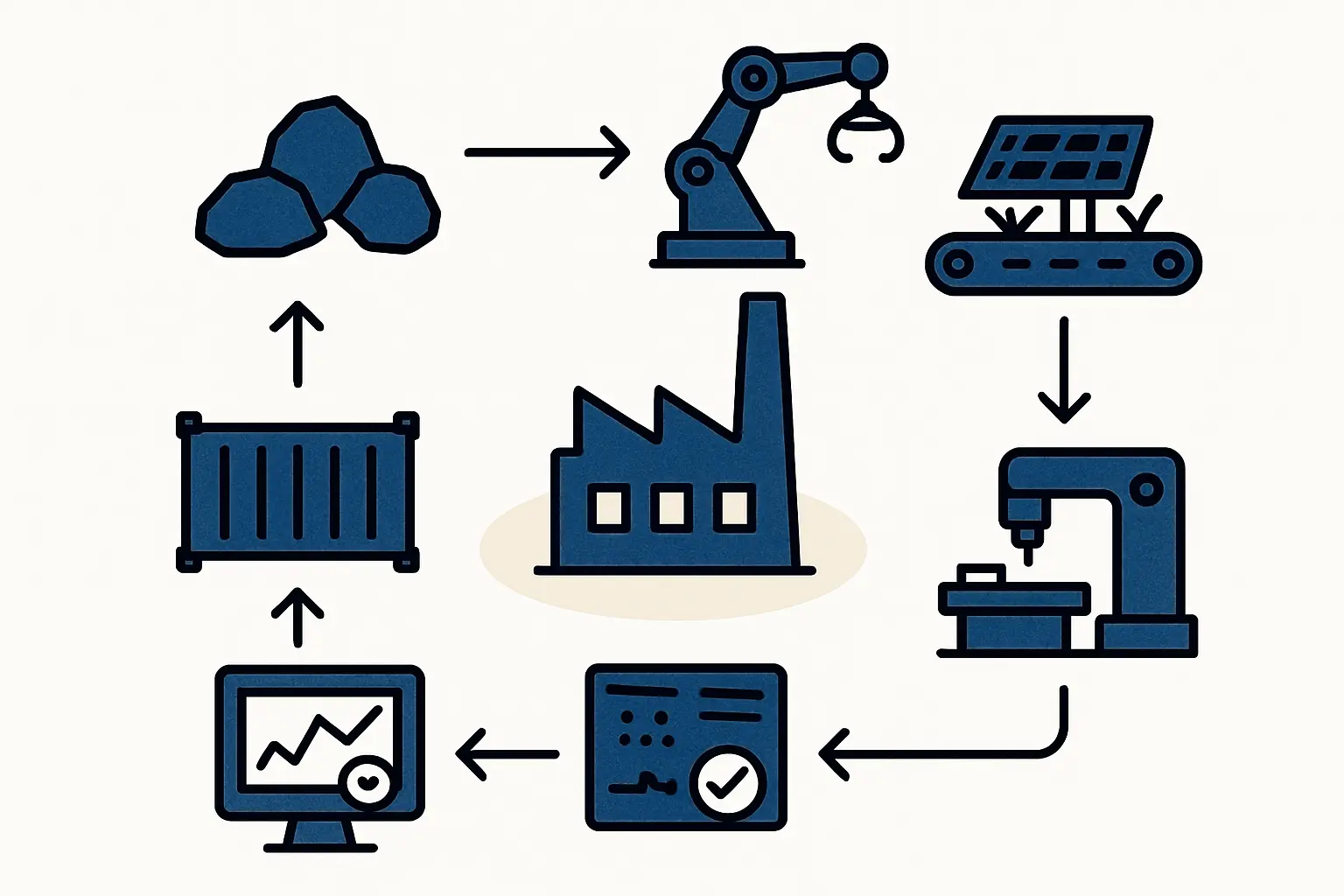

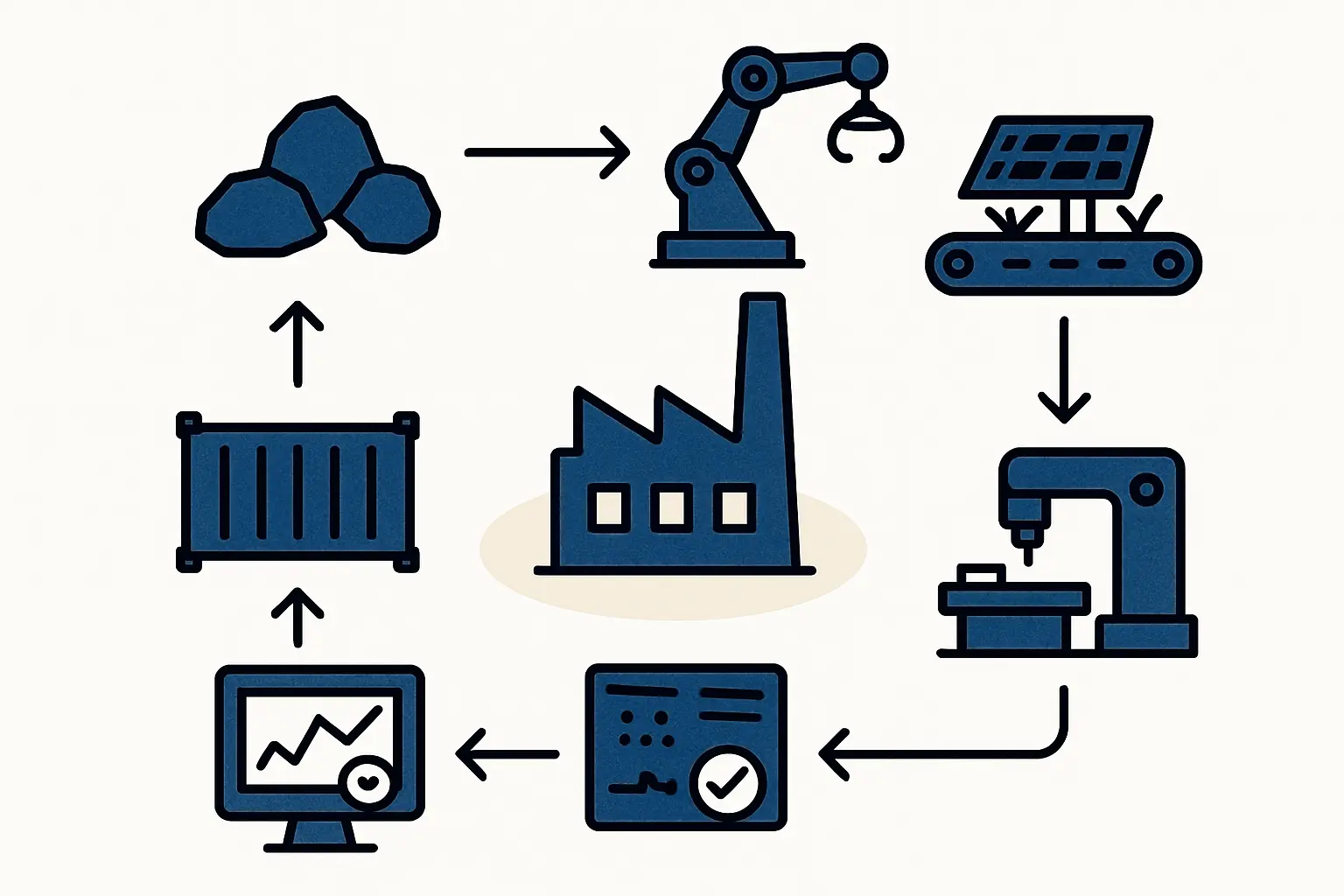

Configuring Your Factory for Bifacial Glass-Glass Production

Entrepreneurs planning to enter this market must ensure their factory is equipped to handle Glass-Glass production. While many machines in a standard production line can be used, a few key stations require specific capabilities. Based on experience from J.v.G. turnkey projects, the focus should be on the lamination, testing, and framing stages.

The overall manufacturing process for G-G modules is similar to that of standard modules, but success hinges on the details in equipment selection.

Key Equipment Considerations

-

Laminator: This machine uses heat and pressure to encapsulate the solar cells between the two panes of glass and encapsulant layers. A laminator for G-G production must have precise temperature control to process the thicker assembly without causing cell damage or delamination. Multi-chamber laminators are often preferred for their higher throughput and process control.

-

Sun Simulator (IV Tester): To certify a module’s power output, it must be tested under standard conditions. For bifacial modules, the sun simulator must be capable of testing both the front and rear sides. A “dual-side” or “bifacial” tester is essential for accurate quality control and for providing customers with a reliable bifaciality factor (the ratio of rear-side to front-side efficiency).

-

Framing Station: Many Glass-Glass modules are installed frameless to reduce shading on the rear side. However, some clients may require specialized frames. The framing station must be versatile enough to handle both frameless modules and apply custom frames as needed.

Setting up a turnkey production line configured for G-G modules requires careful selection of all manufacturing equipment. This initial investment in flexibility allows a manufacturer to serve both the high-value agrivoltaics niche and the broader market for high-performance bifacial panels.

Frequently Asked Questions for New Entrants

Is a Glass-Glass production line significantly more expensive than a standard Glass-Foil line?

The initial investment is moderately higher, primarily due to the need for a more capable laminator and a dual-side sun simulator. However, this investment provides greater manufacturing flexibility and future-proofs the factory, allowing it to produce higher-margin products for specialized markets.

Can the same production line produce both Glass-Glass and Glass-Foil modules?

Yes. A well-designed production line with a flexible laminator and handling systems can switch between G-G and G-F production. This versatility allows a manufacturer to serve different market segments from a single factory.

What is a typical investment for a 50 MW factory targeting this market?

The investment for equipment in a 50 MW semi-automated factory capable of producing G-G bifacial modules typically ranges from €2.5 million to €4 million. The exact figure depends on the level of automation and the specific equipment suppliers chosen.

How does pvknowhow.com assist with this process?

The pvknowhow.com platform provides structured educational resources, including an online course, that guide entrepreneurs through the entire process—from initial business planning and factory design to equipment selection and operational setup. The platform equips non-experts with the knowledge needed to make informed investment decisions.

Your Next Steps in a Growing Market

The Italian agrivoltaics initiative offers a clear and lucrative entry point into the solar manufacturing industry. Unlike commodity markets, it rewards manufacturers who focus on specialized, high-quality products.

Success depends on a clear strategy: designing a production facility to build the specific bifacial Glass-Glass modules that meet the country’s stringent regulatory requirements. Aligning manufacturing capabilities with this well-defined market demand allows new entrepreneurs to build a competitive and profitable business.

With the right planning and technical guidance, this opportunity is accessible even to those without a background in photovoltaics.