A common concern for entrepreneurs considering a solar module factory is the availability of a skilled workforce. Many assume such a high-tech venture requires a deep pool of experienced photovoltaic engineers and technicians—a resource that seems scarce in many emerging markets.

Experience from numerous turnkey projects, however, reveals a different reality. The critical factor for success isn’t pre-existing expertise but a well-structured system for training a motivated and capable local team.

This assessment examines the labor landscape in Ivory Coast and outlines a practical framework for recruiting and training local personnel. The goal is to build a team that can meet the quality standards of a modern solar production line, transforming the country’s demographic potential into a manufacturing asset.

Understanding the Ivorian Labor Landscape

An effective workforce strategy begins with understanding the local labor market. For an industrial investor, Ivory Coast presents a distinct set of opportunities and challenges.

Demographic Potential

The country has a remarkably young population, with nearly 60% of its citizens under the age of 25. This youth bulge represents a vast and energetic potential workforce. National statistics also indicate a significant unemployment rate, particularly among young adults, suggesting a high level of labor availability for new industrial projects.

Educational Foundation

The Ivorian government has made substantial investments in education. However, reports from international development agencies and local business chambers frequently highlight a gap between theoretical knowledge and the practical, hands-on skills required by industry. Many graduates, while educated, lack specific vocational experience.

This context is crucial. A recruitment strategy focused solely on finding experienced solar technicians would likely fail. The real opportunity lies not in finding ready-made experts, but in identifying individuals with the right aptitude and providing them with world-class, process-oriented training.

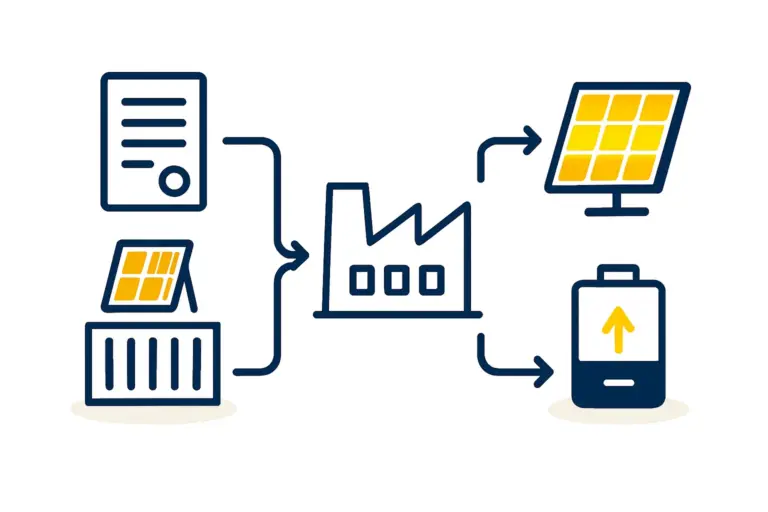

Key Roles in a Solar Module Assembly Line

A semi-automated turnkey solar production line doesn’t require every employee to be a highly qualified engineer. The work is divided into specific, trainable roles. For a typical 20-50 MW factory, the core team consists of:

-

Machine Operators: These team members are responsible for running specific stations, such as the stringer, layup station, or laminator. The primary requirement is diligence, attention to detail, and the ability to follow standardized procedures.

-

Technicians: This group handles machine setup, calibration, routine maintenance, and troubleshooting. A background in mechanics or electronics from a technical school is advantageous but not always essential.

-

Quality Control (QC) Inspectors: Positioned at critical points in the production line, these employees perform visual inspections, run tests like EL and sun simulation, and ensure every module meets specifications. A meticulous and uncompromising approach to quality is the key trait.

-

Supervisors and Line Managers: These leaders oversee the production flow, manage the teams, and ensure targets for output and quality are met. They are often promoted from the ranks of the most capable operators or technicians.

Ultimately, this structure means the majority of roles are accessible to people with a solid general education and the right attitude, provided they receive proper training.

A Framework for Recruitment and Training

A successful human resources strategy is built on two pillars: intelligent sourcing and systematic training.

Sourcing and Selection Strategy

Instead of posting advertisements for ‘Solar Technicians’, a more effective approach is to recruit for aptitude and potential.

-

Focus on Transferable Skills: Look for candidates from industries that require precision and process discipline, such as electronics assembly, textiles, or food processing. Their experience with production machinery and quality standards is directly transferable.

-

Assess Aptitude and Attitude: During the hiring process, prioritize candidates who demonstrate strong problem-solving skills, a willingness to learn, and a disciplined work ethic. Simple manual dexterity tests can also be effective predictors of success for operator roles.

-

Partner with Technical Institutes: Engage with local vocational and technical schools. These institutions can be a valuable source of candidates who possess a foundational understanding of technical principles, even if they lack specific solar industry experience.

The Importance of a Structured Training Program

Once a team is recruited, a comprehensive training program is the most critical investment. This is where raw potential is shaped into a high-performing production unit.

A structured training program combines classroom theory with extensive hands-on practice on the actual production equipment.

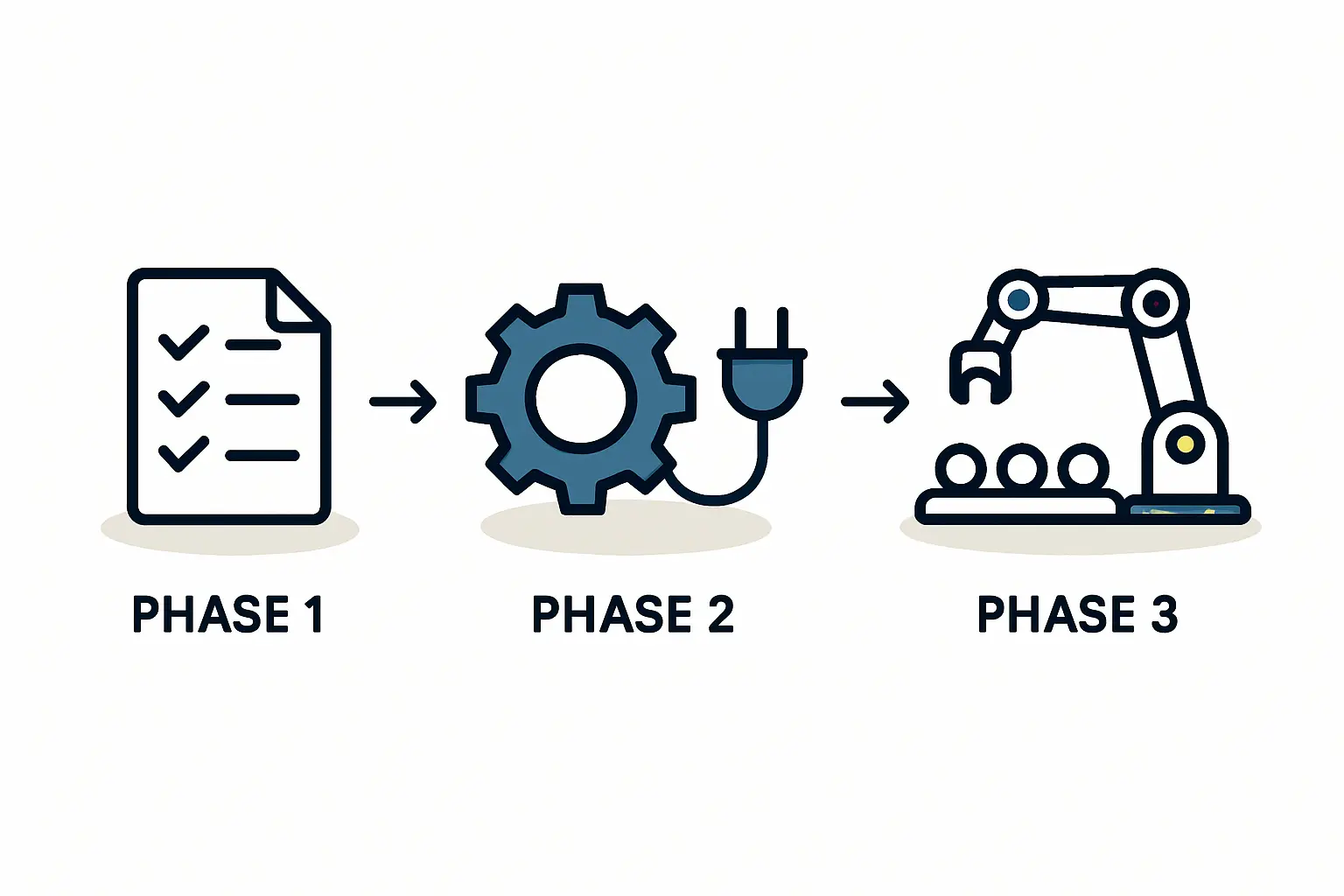

A best-practice training regimen, often provided as part of a turnkey factory setup, includes:

-

Classroom Instruction: This covers the fundamentals of photovoltaic technology, the complete solar panel manufacturing process, quality standards, and safety protocols.

-

Hands-On Equipment Training: An experienced engineer guides the new team through every step of operating and maintaining each machine. This phase, which typically lasts several weeks on turnkey projects, is crucial for building confidence and competence.

-

Ramp-Up Supervision: After the initial training, an expert remains on-site to supervise the first production runs. This ensures that proper procedures are followed, quality issues are addressed immediately, and the local team becomes self-sufficient.

This methodical approach to training effectively bridges the experience gap, ensuring the factory can produce modules to international standards from day one.

Estimated Labor Costs and Team Size

For business planning, it’s useful to have a general estimate of labor requirements. A semi-automated solar module assembly line with an annual capacity of 20-50 MW typically requires a workforce of 25 to 35 employees. This includes operators for one shift, technicians, quality control personnel, supervisors, and essential administrative staff.

Labor costs in Ivory Coast are competitive, offering a significant advantage for manufacturing. However, investors should plan for wages that can attract and retain quality employees, thereby reducing turnover and protecting the investment made in their training.

Frequently Asked Questions (FAQ)

Do I need to hire foreign experts for long-term operations?

Most projects have one or two expatriate experts on-site for the initial 6-12 months to oversee the ramp-up and complete the training of the local management team. The goal, however, should be a fully self-sufficient local operation.

How long does it take to train a new production team from scratch?

A comprehensive training program for a completely new team typically takes 4 to 6 weeks. This is followed by a supervised ramp-up period of several months to achieve target efficiency and quality levels.

What are the most critical skills to look for when hiring operators?

Attention to detail is paramount. The ability to meticulously follow a standardized work instruction without deviation is more important than any prior technical knowledge. A history of working in a quality-focused environment is a strong indicator of suitability.

How does automation affect labor requirements?

Higher levels of automation reduce the number of operators needed for manual handling tasks. However, this often increases the need for skilled technicians who can maintain and troubleshoot more complex production equipment. The choice of automation level should be balanced against local labor costs and skill availability.

Conclusion: Building a Capable Workforce

The success of a solar module factory in Ivory Coast does not depend on finding a pre-existing pool of solar experts. It depends on an investor’s commitment to implementing a systematic process for selecting and training local talent.

The region’s young, available, and motivated population represents a significant asset. By combining this human potential with proven training methodologies and process-driven management, entrepreneurs can build a capable and cost-effective team, ready to produce high-quality solar modules for a growing market. The key is to view the workforce not as a prerequisite, but as a component of the business to be developed with the same precision as the factory itself.