A container of high-value solar cells arrives at port, perfectly on schedule. But a minor documentation error leaves it uncleared for two weeks. The delay halts the production line, incurs significant demurrage fees, and puts project timelines at risk.

This scenario, all too common for new importers, underscores a critical reality: in solar manufacturing, a world-class production line is only as strong as its supply chain. This logistical framework isn’t a minor detail—it’s the strategic foundation of the entire operation.

For entrepreneurs planning to establish solar module production in West Africa, selecting the right port of entry is a crucial first decision. This analysis examines the practical considerations of using Ivory Coast’s two primary maritime gateways—the Port of Abidjan and the Port of San-Pédro—for importing essential raw materials like solar glass, cells, and EVA films.

Understanding the Strategic Importance of Port Selection

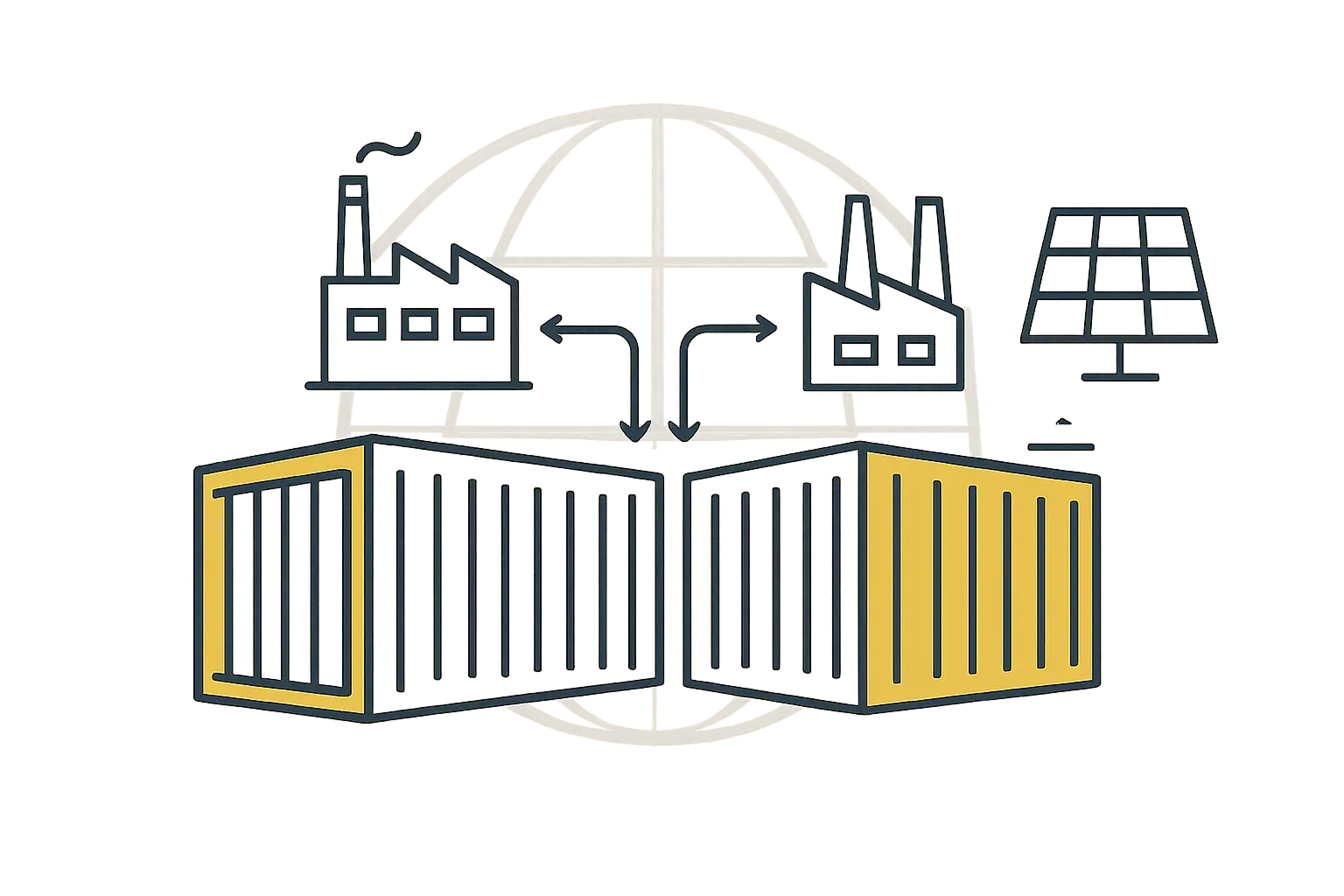

The choice between Abidjan and San-Pédro is about more than geography; it influences timelines, costs, and operational risks. Each port has its own profile of capacity, infrastructure, and administrative efficiency that must be aligned with a factory’s specific location and production scale. As the primary gateways to Ivory Coast and vital corridors for landlocked nations like Mali, Burkina Faso, and Niger, these ports are the starting point of your physical supply chain.

A Profile of the Port of Abidjan: The Economic Heartbeat

The Autonomous Port of Abidjan is one of the largest and most modern port complexes in West Africa, handling over 24 million tons of cargo annually. Its strategic position and extensive infrastructure make it the default choice for most industrial imports. A significant development came in 2022 with the inauguration of a second container terminal (TC2). This expansion increased the port’s capacity by an additional 1.5 million TEU (twenty-foot equivalent units), aiming to reduce congestion and improve vessel turnaround times.

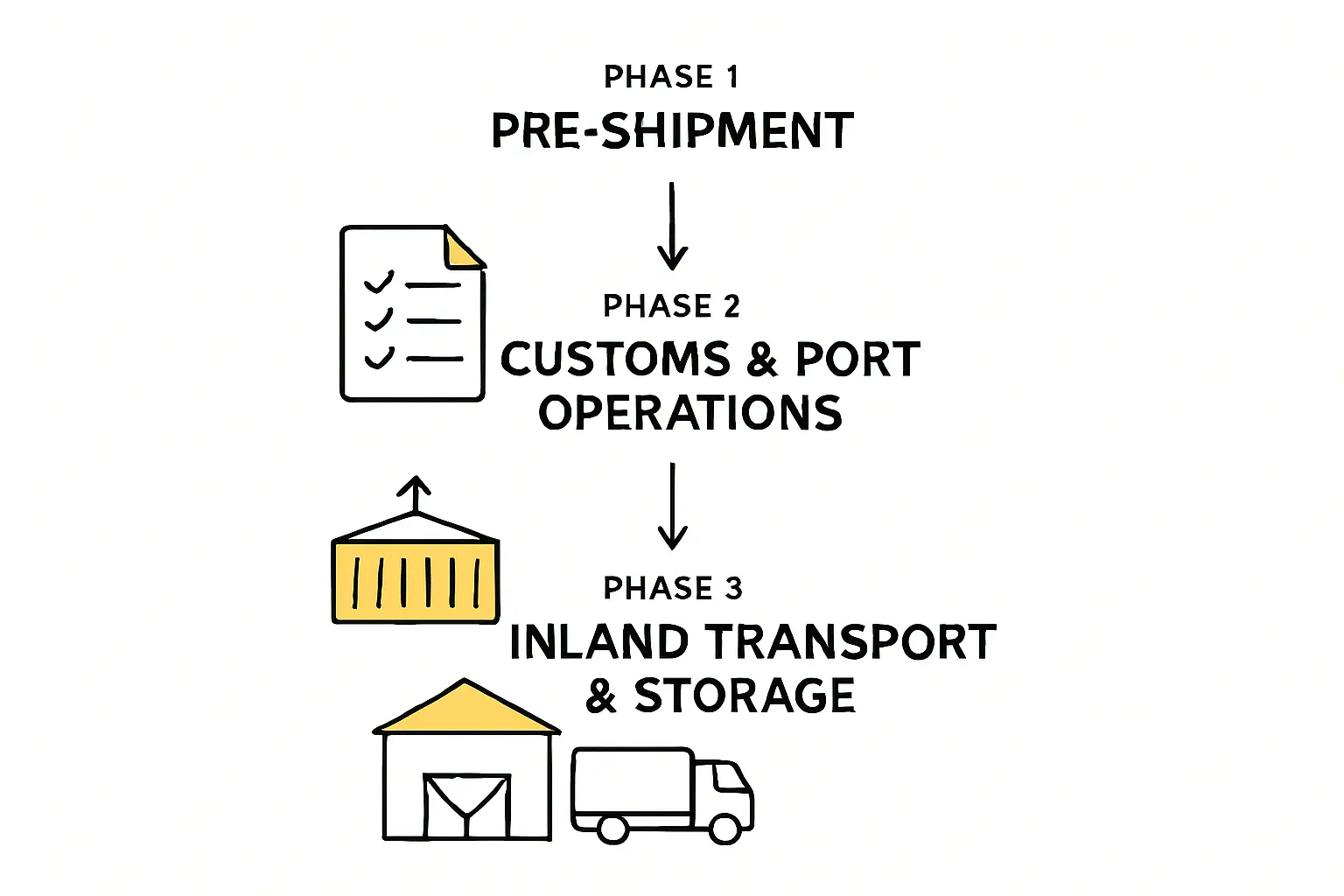

Customs and Clearance Procedures in Abidjan

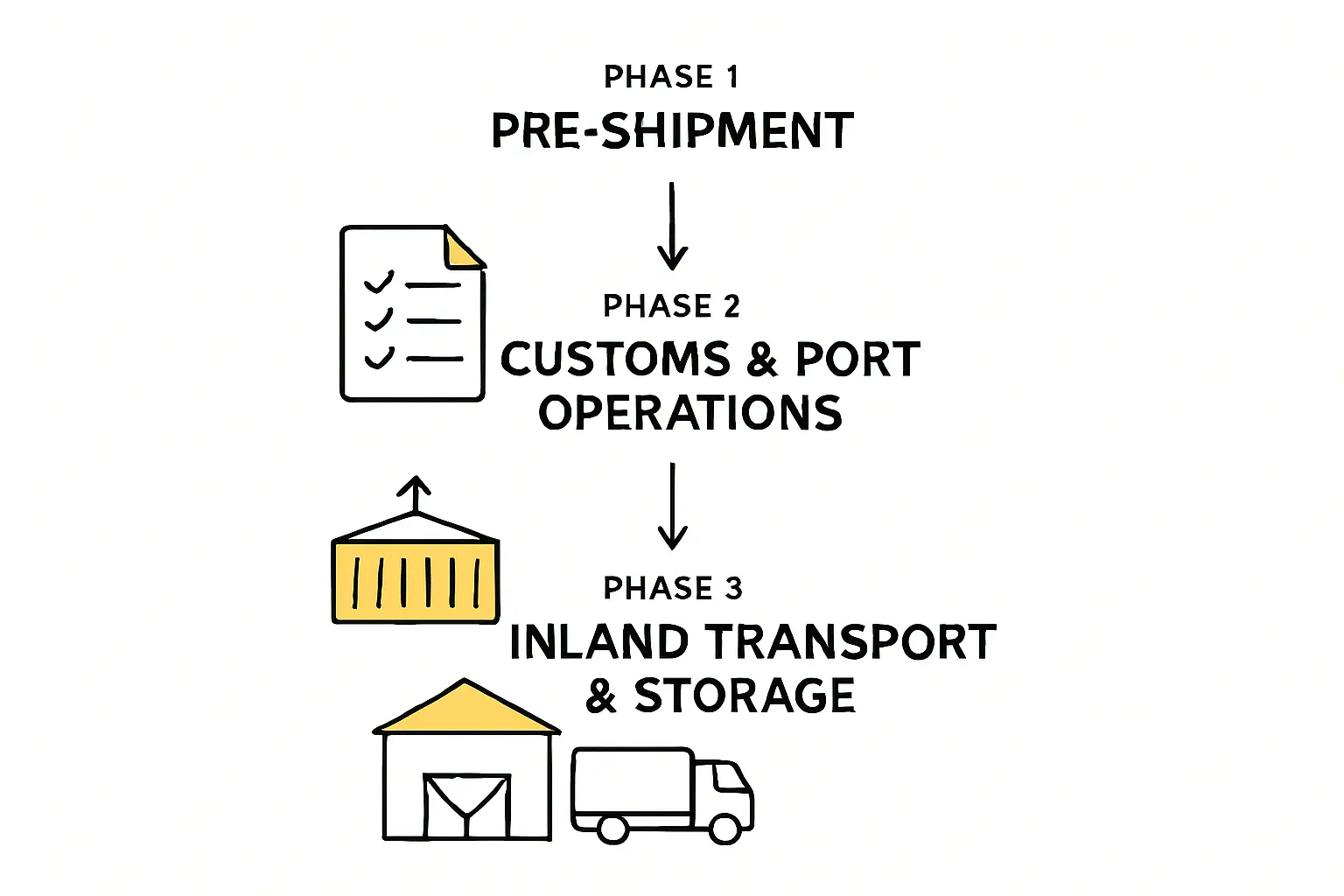

Ivory Coast’s ‘Guichet Unique pour le Commerce Extérieur’ (GUCE) is a single-window system designed to centralize and streamline trade formalities. While this system has improved efficiency, new importers must anticipate a learning curve.

Based on data from recent projects, the average customs clearance time can range from 5 to 15 business days. This timeframe largely depends on the accuracy and completeness of the documentation submitted. For first-time importers, budgeting for the higher end of this range is prudent, as any discrepancies can lead to significant delays and storage costs.

Inland Transport and Infrastructure

Abidjan boasts superior inland connectivity. The port links directly to a network of major highways and the country’s rail system, making it easier to move goods to industrial zones within Ivory Coast and across its borders. The quality of these connections is a significant advantage for factories located further from the coast and supports the broader requirements for a solar factory building and infrastructure.

A Profile of the Port of San-Pédro: The Strategic Alternative

As the world’s leading port for cocoa bean exports, the Port of San-Pédro is a major economic asset for Ivory Coast. While historically focused on agricultural commodities, it is modernizing to handle more diverse cargo, including containers. For businesses located in the western part of the country, or those seeking a less congested alternative to Abidjan, San-Pédro presents a viable option.

Advantages and Considerations for San-Pédro

Due to lower container volumes than Abidjan, customs processing in San-Pédro can sometimes be faster. However, its ecosystem of logistics providers, customs brokers, and specialized transport services is less developed. The road network connecting San-Pédro to the interior is also less robust, which can increase inland transport times and costs, particularly during the rainy season. Entrepreneurs must weigh potentially faster port clearance against the challenges of last-mile delivery.

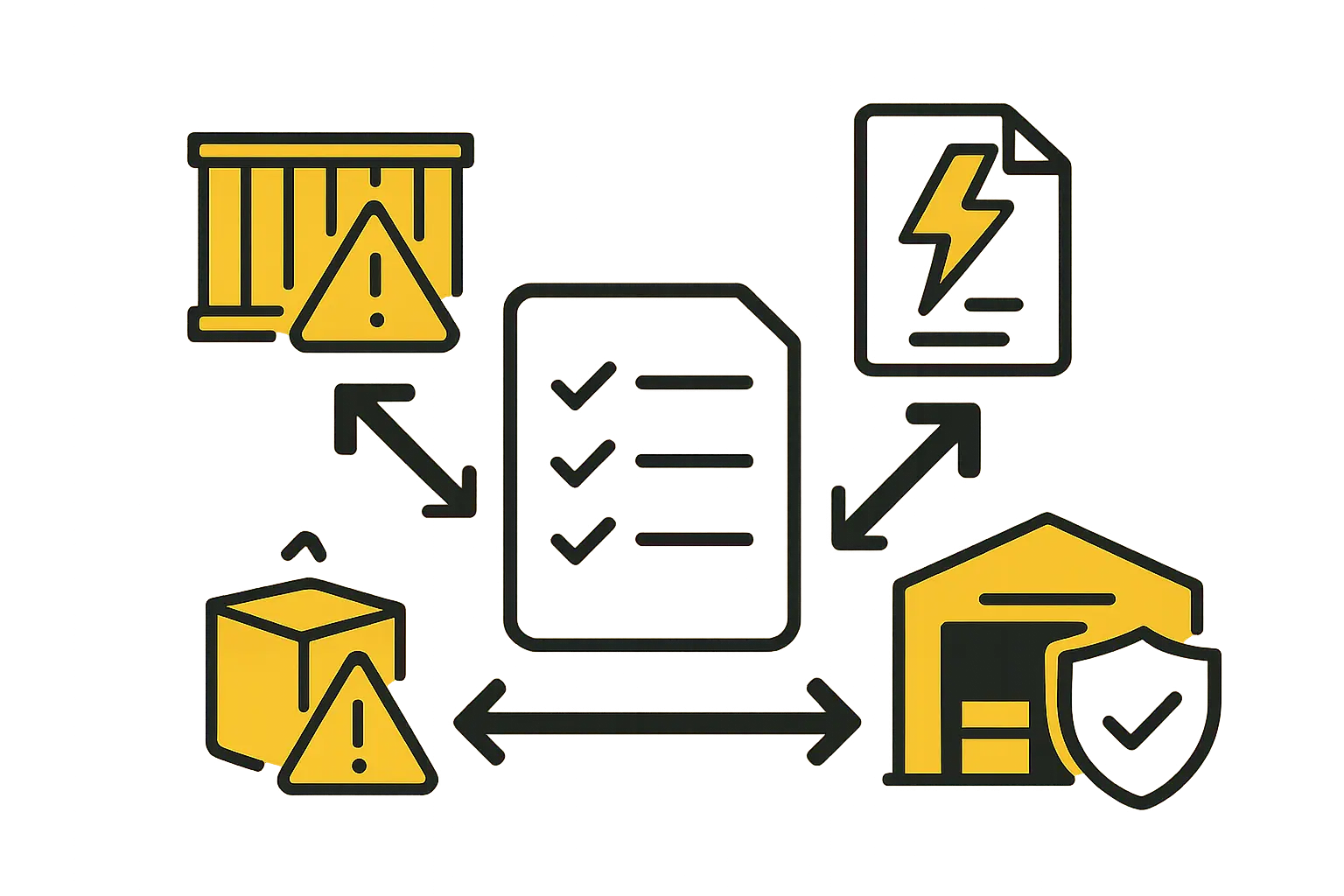

Specific Challenges for Importing Solar Manufacturing Components

The raw materials for solar module manufacturing have unique handling requirements, complicating the import process. A logistics plan must account for the specific nature of each component.

Hanling Solar Glass

Solar glass ships in large, heavy crates. It is bulky and extremely fragile, requiring specialized equipment for offloading and transport to avoid breakage. Any damage can result in significant financial loss, as a single crate can contain glass for hundreds of modules.

Securing Solar Cells

Solar cells are the most valuable and delicate component. They are shipped in specially designed protective boxes, usually palletized within a container. Given their high value, secure warehousing—both at the port and at the factory site—is non-negotiable to prevent theft or damage.

Storing EVA and Backsheets

Encapsulant films (EVA) and backsheets are typically shipped in rolls. These materials are sensitive to moisture and high temperatures, which can compromise their quality and performance. Access to climate-controlled warehousing is essential to protect their integrity before they enter production. The proper handling of these items is a critical part of the overall solar module manufacturing process.

Key Business Considerations for Your Supply Chain

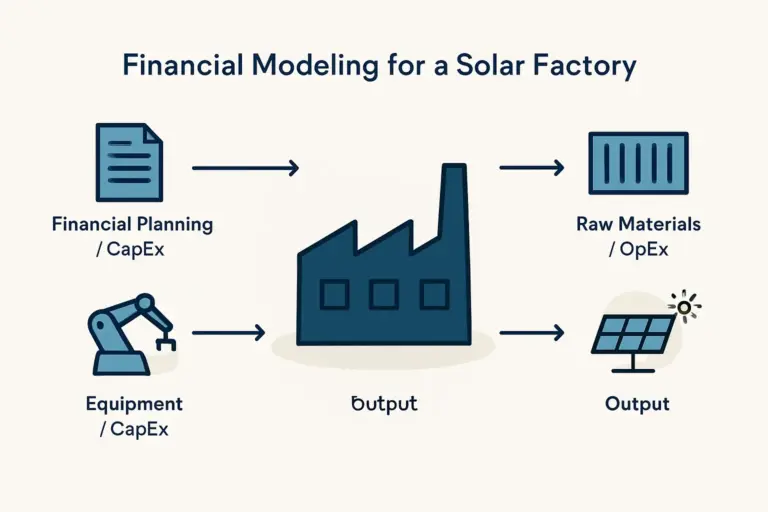

Based on experience from J.v.G. turnkey projects, logistical planning is as critical as machine selection. A successful plan must account for several key business factors.

Navigating Tariffs and Regulations

Ivory Coast is a member of the Economic Community of West African States (ECOWAS), which applies a Common External Tariff (CET) to imports. However, national and regional policies often provide duty exemptions or reductions for renewable energy equipment. Working with an experienced local customs broker is essential to verify the applicable tariff codes and ensure all potential exemptions are claimed.

Cost Analysis: Port Fees, Inland Transport, and Demurrage

A comprehensive budget must include port handling charges, customs fees, and inland transportation costs. A critical, often overlooked cost is demurrage—a penalty charged by the shipping line for failing to collect a container within a specified free period. Customs delays are a primary cause of demurrage, and these fees can accumulate rapidly.

Selecting a Logistics Partner

Engaging a reliable local logistics partner is paramount. The ideal partner will have demonstrable experience not just with imports, but with handling fragile, high-value industrial components. They must be able to navigate the customs system efficiently and provide secure, reliable inland transport and warehousing solutions.

Frequently Asked Questions (FAQ)

Which port is better for a new solar factory?

The choice depends on the factory’s location. For facilities in or around Abidjan, or those relying on the rail network, the Port of Abidjan is the logical choice. For factories in western Ivory Coast, San-Pédro could offer advantages, provided the inland transport infrastructure is deemed adequate.

How long should I budget for customs clearance?

For initial shipments, plan for 10-15 business days to account for potential administrative hurdles. As your process becomes established, this time may decrease.

Are there special permits required for solar components?

Generally, solar components do not require special import permits beyond standard customs declarations. However, it is essential to confirm this with a local customs authority or broker, as regulations can change.

Can materials be transported directly from the port to a factory in a neighboring country like Mali?

Yes. Both ports, particularly Abidjan, are well-established transit hubs. Goods can be moved under a customs transit bond to landlocked countries. This process adds administrative complexity and requires a logistics partner experienced in cross-border transit procedures.

Conclusion: Integrating Logistics into Your Business Plan

An effective logistics strategy is a cornerstone of a profitable solar manufacturing operation. The choice of port, the selection of a logistics partner, and a thorough understanding of customs procedures directly impact project timelines and costs.

By treating logistics as a strategic pillar rather than an operational afterthought, entrepreneurs can mitigate risks, control expenses, and build a resilient supply chain. The next logical step is a detailed feasibility study that incorporates local transport costs and customs advisory, a key component when calculating the total investment for a solar module factory.