An investor considering the solar manufacturing sector often starts with one critical question: What is the true cost? Moving from a business concept to a concrete financial model is the first major step. For an entrepreneur in a dynamic market like Ivory Coast, this means developing a detailed understanding of both universal manufacturing costs and the specific economic realities of the region.

This analysis offers a structured breakdown of the investment and operational costs for establishing a 50-megawatt (MW) solar module assembly factory in Ivory Coast. It serves as a foundational guide to help transform a strategic vision into a viable business plan.

The Ivorian Context for Solar Manufacturing

Ivory Coast presents a compelling case for local solar production. The fundamentals are promising: strong economic growth, a government committed to increasing renewable energy capacity, and a strategic location with the port of Abidjan serving as a gateway to West Africa. Even as the national electrification rate rises, demand continues to outpace supply, creating a sustainable market for locally produced solar modules.

A realistic financial model, however, must also account for local challenges like navigating administrative processes, managing supply chain logistics, and ensuring a stable power supply for the factory itself. A clear grasp of this landscape is crucial for accurate forecasting.

Capital Expenditure (CapEx): The Initial Investment

Capital expenditure covers the one-time investment required to take the factory from a plan on paper to a fully operational facility. For a 50 MW line, this is a significant undertaking broken down into several key areas.

Land and Building

A modern 50 MW solar module assembly line requires a dedicated facility with specific characteristics. The total space needed is typically 3,000 to 5,000 square meters to accommodate the main production hall, warehousing for raw materials and finished goods, offices, and utility rooms.

Land Acquisition: Costs vary by location. Securing a plot in an industrial zone near Abidjan, such as the PK 24 Industrial Zone of Akoupé-Zeudji, offers advantages in logistics and infrastructure.

Building Construction: The facility itself should be a steel-frame industrial building with a dust-free environment, appropriate flooring for heavy machinery, and sufficient height for material handling. In Ivory Coast, the construction cost for such a structure is a primary budget component.

Production Equipment

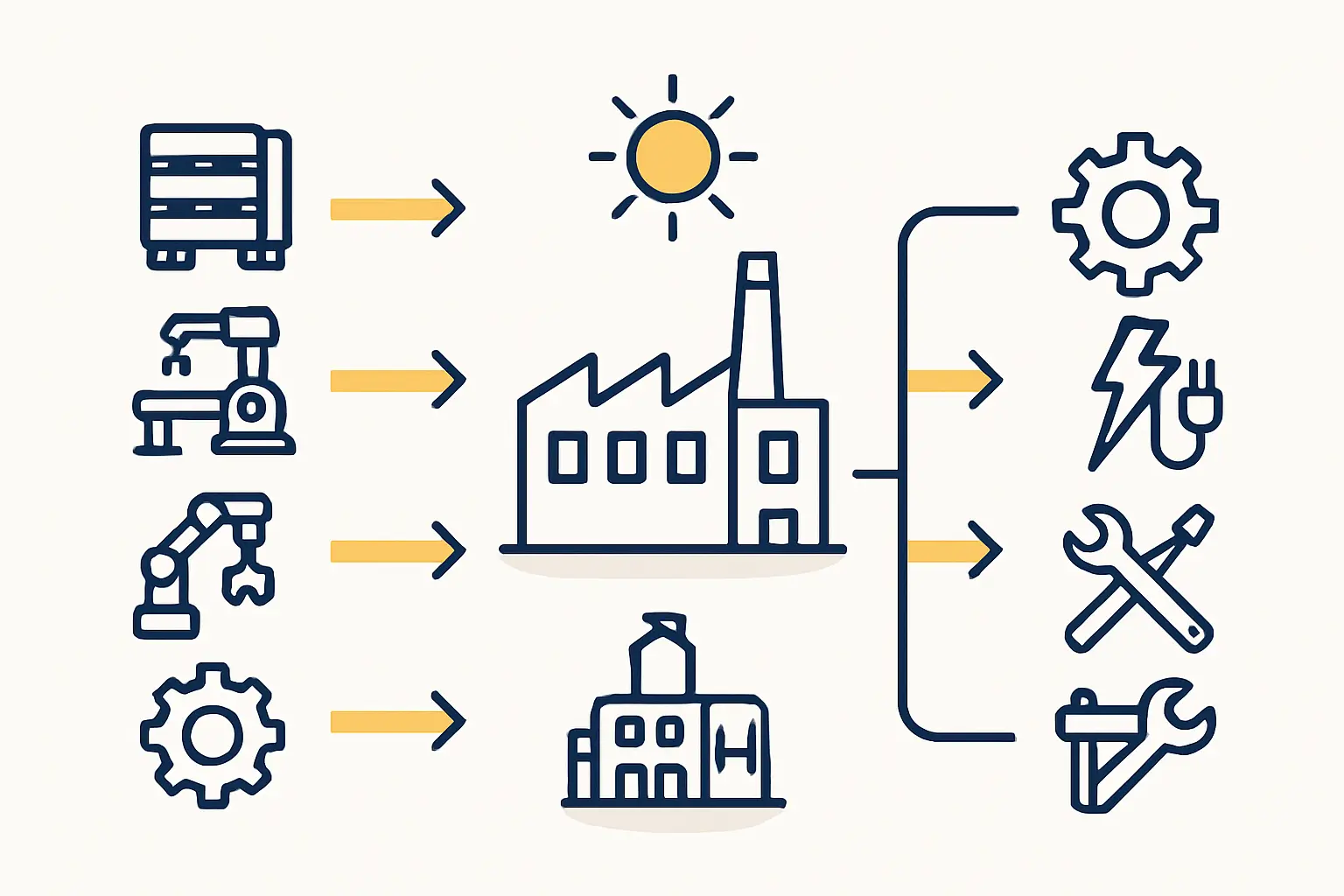

The machinery is the heart of the factory and the largest single item in the CapEx budget. A semi-automated 50 MW line includes several critical machines working in sequence, and selecting reliable, serviceable equipment is paramount to long-term success.

Key equipment includes:

- Automatic Cell Stringer: Connects individual solar cells into strings.

- Layup Station: Assembles the module layers (glass, EVA, cell strings, backsheet).

- Laminator: Fuses the layers together under heat and vacuum.

- Framing Machine: Attaches the protective aluminum frame.

- Junction Box Applicator: Mounts the electrical junction box.

- Sun Simulator / IV Tester: Tests the finished module’s performance.

Understanding the complete solar module manufacturing process is essential before finalizing equipment specifications.

Ancillary and Utility Infrastructure

Beyond the main production line, a significant investment is needed for supporting infrastructure.

- Electrical System: A dedicated transformer and high-capacity electrical panels are necessary.

- Backup Power: Given potential grid instability, a properly sized diesel generator is a non-negotiable investment to ensure uninterrupted production.

- Compressed Air System: Many automated machines rely on a clean, dry supply of compressed air.

- HVAC System: Climate control maintains optimal temperature and humidity for certain production steps, particularly lamination.

Initial Setup and Commissioning

This category covers costs often overlooked in preliminary budgets, including equipment shipping to Abidjan, inland transport, professional installation, and fees for expert engineers to commission the line and train the initial team of local operators and technicians. Experience from J.v.G. turnkey projects shows this phase is critical for a smooth startup.

Sample CapEx Breakdown for a 50 MW Factory in Ivory Coast

| Category | Estimated Investment (USD) | Notes |

|---|---|---|

| Land & Building (5,000 m²) | $600,000 – $900,000 | Varies greatly with location and land status (lease vs. purchase). |

| Production Equipment | $1,800,000 – $2,500,000 | For a reliable semi-automated line from a reputable supplier. |

| Utility Infrastructure & Backup Power | $200,000 – $350,000 | Includes transformer, generator, and compressed air systems. |

| Shipping, Installation & Training | $150,000 – $250,000 | Covers logistics, commissioning, and knowledge transfer. |

Total Estimated CapEx: $2,750,000 – $4,000,000

Note: Excludes working capital and pre-operational expenses.

Operational Expenditure (OpEx): The Ongoing Costs

Once the factory is operational, these recurring expenditures determine the cost of producing each solar module and must be carefully managed to ensure profitability.

Raw Materials (Bill of Materials – BOM)

Raw materials are typically the largest component of OpEx, accounting for over 80% of a finished module’s cost. Prices for these commodities fluctuate on the global market.

- Solar Cells

- Tempered Glass

- EVA (Ethylene Vinyl Acetate) film

- Backsheet

- Aluminum Frames

- Junction Boxes & Cables

Labor

A semi-automated 50 MW line operating on a single shift requires a team of 30 to 40 employees.

- Production Staff: Operators, technicians, quality control inspectors.

- Support Staff: Warehouse managers, maintenance engineers, administrative personnel.

Salaries must be budgeted in line with Ivorian labor laws and market rates for skilled and semi-skilled industrial workers.

Utilities

Electricity is the primary utility cost. A 50 MW line consumes significant power, particularly for the laminator and HVAC system, so the industrial electricity tariff from the Compagnie Ivoirienne d’Électricité (CIE) must be factored into the model. Water consumption is comparatively low.

Maintenance and Overheads

This budget covers scheduled machinery maintenance, spare parts, factory insurance, security services, and other general and administrative expenses. A common practice is to budget 1–2% of the total equipment cost annually for spare parts and maintenance.

Sample Monthly OpEx at Full Single-Shift Capacity

| Category | Estimated Monthly Cost (USD) | Notes |

|---|---|---|

| Raw Materials (BOM) | $1,200,000 – $1,600,000 | Based on producing ~4.1 MW per month; highly variable with market prices. |

| Labor (35 employees) | $20,000 – $30,000 | Includes salaries and social contributions. |

| Utilities (Electricity & Water) | $15,000 – $25,000 | Primarily driven by electricity consumption. |

| Maintenance & Overheads | $10,000 – $20,000 | Includes spares, insurance, security, and administrative costs. |

Total Estimated Monthly OpEx: $1,245,000 – $1,675,000

Note: Illustrates the importance of working capital for raw materials.

Synthesizing the Financial Model

With these figures, an entrepreneur can begin to build a foundational financial model. The total Year 1 cash requirement, for example, would include the full CapEx plus at least three to six months of OpEx as working capital. This initial fund finances the procurement of raw materials and covers costs before revenue stabilizes.

A common challenge for new entrants is underestimating the working capital needed to sustain a smooth supply of raw materials, a lesson illustrated by a past client, Mr. Goyal in India. This highlights the importance of not just funding the initial setup, but ensuring the business is capitalized to manage its ongoing operational cash flow. A robust financial plan must look beyond the initial investment to the full operational lifecycle, including the need to obtain necessary factory certifications to access certain markets.

Frequently Asked Questions (FAQ)

What is the typical timeline from investment decision to first production?

For a turnkey project of this scale, a realistic timeline is 9 to 12 months. This period covers factory construction, equipment manufacturing and shipping, installation, and commissioning.

Are there government incentives for solar manufacturing in Ivory Coast?

Yes, investors should engage with the Centre de Promotion des Investissements en Côte d’Ivoire (CEPICI). The Ivorian Investment Code offers potential benefits, such as tax exemptions on imported equipment and other fiscal advantages for qualifying projects.

How much working capital is needed in addition to the CapEx?

A prudent budget includes at least three to six months of total operational expenditure as working capital. This ensures the company can purchase raw materials and manage expenses before a steady revenue stream is established.

Can a factory start with a smaller capacity than 50 MW?

Yes, starting with a smaller line of 20–25 MW is a common strategy to reduce initial CapEx. The factory building can be designed to accommodate future expansion, allowing an investor to scale up as the business grows.

Conclusion and Next Steps

Establishing a 50 MW solar module factory in Ivory Coast is a significant industrial project, with an estimated initial capital requirement of $2.75 to $4 million, plus substantial working capital. The success of such a venture hinges on a meticulous financial model that accurately reflects both global equipment costs and local Ivorian economic conditions.

While the figures can seem complex, a structured approach makes the process manageable, even for those new to the solar industry. This cost analysis serves as a first step. To move your project forward, the next logical step is to gain a deeper understanding of machine technicalities or specific building requirements.