An entrepreneur planning to enter the solar manufacturing sector in Jamaica faces unique challenges and opportunities. While global demand provides a strong tailwind, the most significant risk to a solar asset in the Caribbean isn’t market fluctuation but the raw power of nature. A single hurricane can render an entire solar field worthless, undermining investor confidence and destroying long-term returns.

A critical oversight for many new entrants is assuming a standard, internationally certified solar module is adequate for this environment. It isn’t. For a manufacturing venture to succeed in Jamaica and the wider Caribbean, the product must be engineered from the ground up to withstand the region’s specific, extreme weather conditions. This is not just a technical detail; it is the foundation of a sustainable and profitable business model.

Understanding the Threat: Why Standard Solar Modules Fail in Hurricanes

The International Electrotechnical Commission (IEC) sets the global benchmark for solar module quality and safety. Standard tests, such as IEC 61215 and 61730, certify that a module can withstand a static load of 2400 Pascals (Pa).

While this sounds robust, it translates to a wind speed of approximately 160 km/h (100 mph). A Category 3 hurricane already exceeds this threshold. For Jamaica, which is susceptible to Category 4 and 5 storms with wind speeds well over 210 km/h, this standard certification is fundamentally insufficient.

During a hurricane, a solar module endures three primary forces:

-

Positive Pressure: Direct wind force pushing down on the module.

-

Negative Pressure (Uplift): Air moving quickly over the module’s surface creates a lift effect, similar to an airplane wing, that can tear the module from its racking.

-

Oscillating Loads: Rapid, repeated shifts between positive and negative pressure cause the module to flex and vibrate violently, which can lead to microcracks, cell damage, and catastrophic failure.

A standard module, designed for less severe climates, will likely fail under these conditions. This creates a clear imperative for local manufacturers to produce a superior, region-specific product.

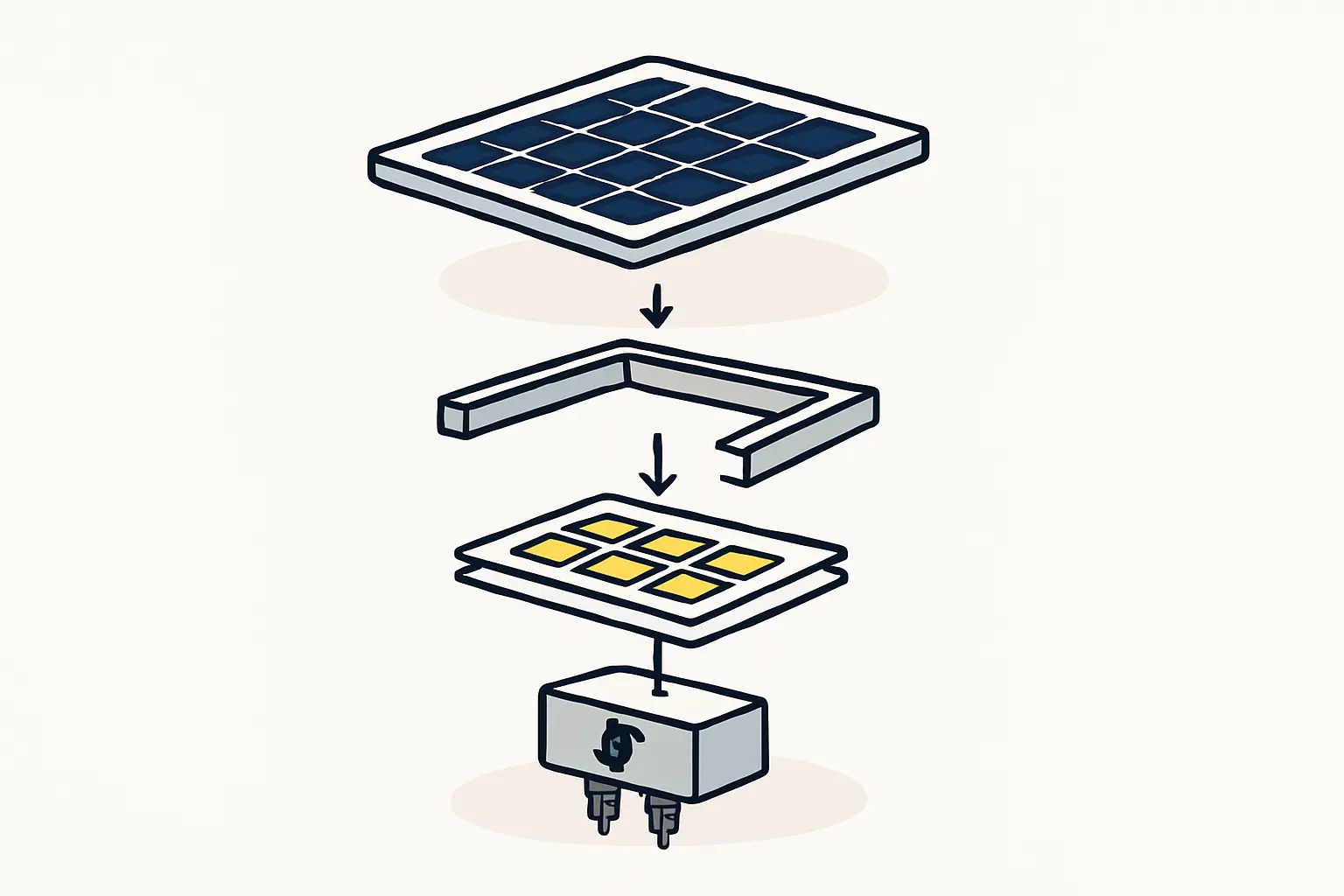

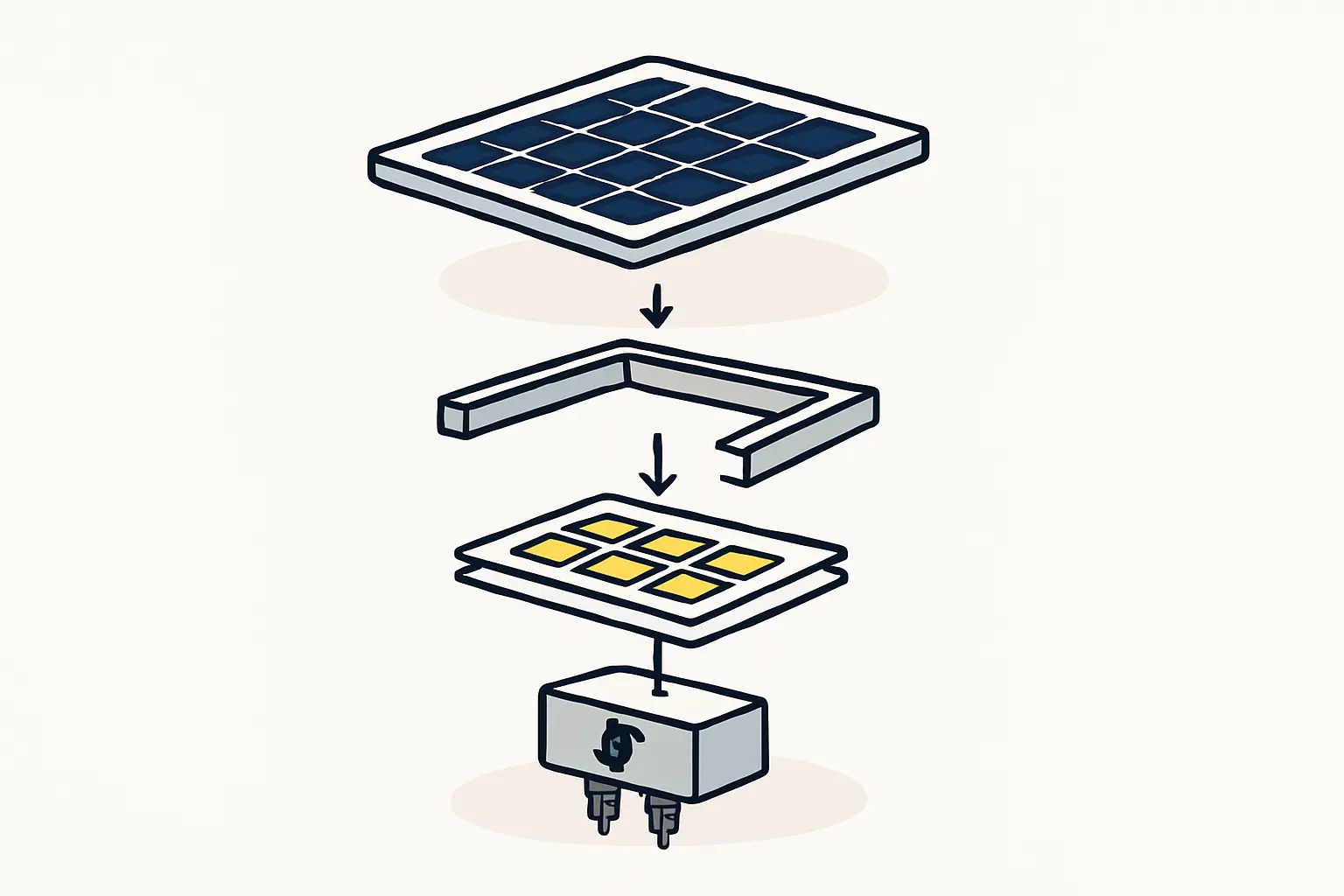

Key Manufacturing Specifications for Hurricane Resilience

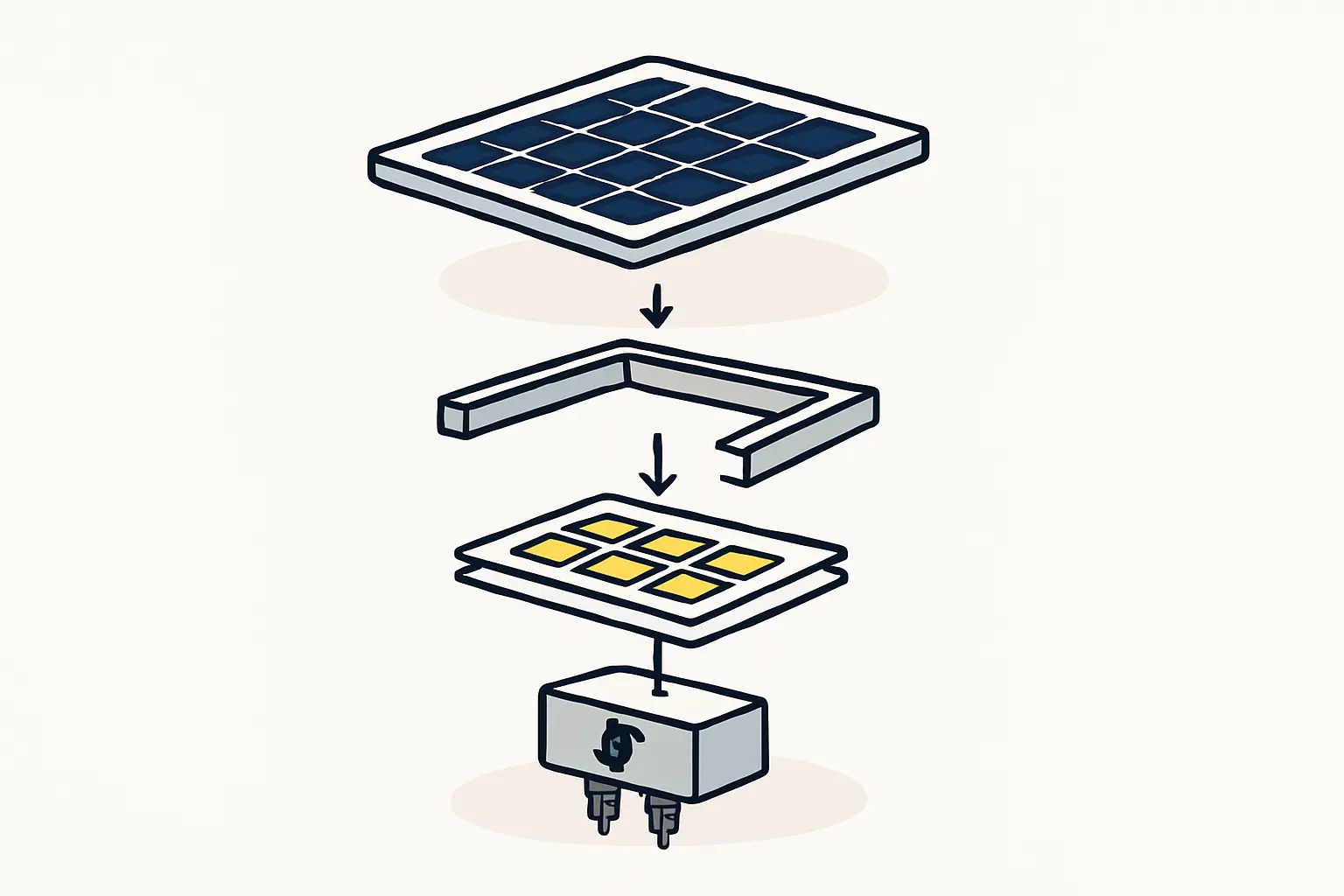

Achieving a higher wind load rating requires specific modifications during the manufacturing process. These are not after-market additions; they are core design choices that must be integrated into the production line. A well-structured solar module manufacturing business plan will account for these material and process adjustments from the outset.

The Foundation: Reinforced Glass

The front glass is the first line of defense. While many global manufacturers use 2.0mm or 2.5mm glass to reduce cost and weight, a module designed for high-wind zones requires a minimum of 3.2mm fully tempered glass. For maximum protection, 4.0mm glass should be considered. This increased thickness significantly improves resistance to both impacts from flying debris and the stress of constant flexing.

The Skeleton: A Stronger, More Rigid Frame

The aluminum frame is the module’s skeleton, providing its structural rigidity. For hurricane resistance, several aspects of the frame must be strengthened.

-

Frame Thickness: The wall thickness of the aluminum profile should be increased, often from a standard 1.5mm to 2.0mm or more.

-

Alloy Selection: Using a stronger aluminum alloy, such as 6005-T6, provides superior mechanical strength compared to more common alloys.

-

Corner Design: The corners are a common point of failure. A robust, securely keyed or screwed corner construction is essential to prevent the frame from twisting and separating under extreme stress.

The Seal: Preventing Water and Air Ingress

The intense, driving rain and pressure changes during a hurricane can force moisture past the edge seals of a standard module, leading to delamination and long-term degradation. Using high-grade sealants and, in some cases, adding a secondary potting compound around the laminate edge provides a crucial barrier. This prevents high-pressure air from getting under the glass—a primary cause of delamination and glass breakage during a storm.

The Connection: Enhanced Mounting Points

A stronger module is only effective if it remains attached to its mounting structure. A hurricane-resistant design incorporates additional, reinforced mounting holes in the frame. This allows installers to use more connection points, distributing the load more evenly across the structure and reducing the chance of a single point of failure.

Beyond Static Tests: The Importance of Dynamic Load Simulation

The standard IEC test applies a static, or constant, load. A hurricane’s gusting winds, however, create a dynamic load that repeatedly flexes the module. This cyclical stress is far more damaging.

Advanced manufacturing facilities use Dynamic Mechanical Load (DML) testing. This test subjects the module to thousands of cycles of alternating pressure, more accurately simulating the conditions inside a hurricane.

Specifying a module that has passed rigorous DML testing to a high standard (e.g., >5400 Pa) is a key differentiator. It provides engineers, insurers, and financiers with verifiable proof that the product is built for its intended environment.

The Business Case for a Localized, Premium Product

Manufacturing a more robust module carries a moderately higher upfront material cost, perhaps 10-15%. However, the business advantages in a market like Jamaica are substantial.

-

Market Leadership: By producing a verifiably hurricane-resistant product, a new manufacturer can immediately establish itself as a premium, trusted local brand.

-

Reduced Risk and Insurability: Projects built with modules designed for local conditions present a lower risk profile. This makes them more attractive to banks for financing and enables project owners to secure more favorable insurance terms.

-

Long-Term Viability: A business built on products that fail every few years will not survive. A reputation for durability is a manufacturer’s most valuable asset, especially when starting a solar panel factory in Jamaica.

Experience from turnkey projects in climatically diverse regions, such as those by J.v.G. Technology GmbH, shows that investing in a resilient product specification from day one is the most reliable path to long-term profitability.

Frequently Asked Questions (FAQ)

What specific wind load rating should a manufacturer in Jamaica aim for?

A rating of 5400 Pa (or higher) for both positive and negative loads is a strong target. This significantly exceeds the IEC standard and provides a safety margin for high-category hurricane conditions. Passing a DML test at this level is a key indicator of quality.

Isn’t it cheaper to simply import these specialized modules?

While possible, importing presents challenges with supply chain reliability, shipping costs, and a lack of quality control oversight. Local manufacturing allows for direct supervision of the production process, customization for large-scale projects, and resilience against global shipping disruptions. It also fosters local economic development and technical expertise.

Are there official ‘hurricane-proof’ certifications?

The terminology can vary, but reputable testing bodies like TÜV Rheinland offer certifications for modules that pass extended stress tests, including higher wind loads and DML. A manufacturer should aim to certify its product to these higher, non-mandatory standards to formally validate its claims.

From Standard Production to Regional Leadership

For an entrepreneur entering the solar industry in Jamaica, the path to success is not in competing with low-cost, standard modules from mass-market producers. The true opportunity lies in specialization.

By engineering and manufacturing a product specifically designed to withstand the region’s most severe weather, a new enterprise can build a powerful and enduring competitive advantage. It moves the conversation from price per watt to long-term value, asset security, and peace of mind—qualities that resonate deeply with serious investors and project developers in the Caribbean. This approach transforms a regional liability into a manufacturing imperative and, ultimately, a mark of market leadership.