Disclaimer: This case study represents a composite example derived from real-world

consulting work by J.v.G. Technology GmbH in solar module production and factory optimization. All data points are realistic but simplified for clarity and educational purposes.

Jordan faces a profound paradox: it is blessed with some of the world’s most abundant solar resources, yet it is one of the most water-scarce nations on Earth.

For the thousands of farmers in the Jordan Valley, this is a daily reality. The rising cost of diesel for water pumps and the phasing out of energy subsidies are creating immense economic pressure, threatening both livelihoods and the nation’s food security.

This challenge, however, also presents a significant industrial opportunity. A clear and urgent domestic market exists for affordable, reliable energy for water pumping. This article makes the business case for establishing a specialized solar module factory in Jordan—a venture designed to directly address the needs of the agricultural sector and align with national strategic goals.

The Market Opportunity: Jordan’s Water-Energy Nexus

The business case is rooted in the core challenges facing Jordanian agriculture. The numbers paint a clear picture of a market ripe for a localized, sustainable solution.

- Critical Water Scarcity: Jordan’s per capita water availability is over 80% below the recognized water poverty line. This scarcity directly impacts agricultural productivity and sustainability.

- High Agricultural Demand: The agricultural sector is the country’s largest water consumer, accounting for over 50% of total resources. Much of this water is drawn from groundwater reserves.

- Unsustainable Extraction: Groundwater is being extracted at approximately 150% of its safe yield, leading to falling water tables and increased pumping depths. This, in turn, requires more energy.

- Economic Pressure on Farmers: With the gradual removal of government energy subsidies, the cost of operating traditional diesel-powered water pumps is becoming prohibitive for many of the estimated 15,000 farms in the Jordan Valley.

These pressures create a powerful incentive for farmers to adopt solar water pumping. With solar irradiation levels between 5 and 7 kWh/m²/day, Jordan is an ideal location for photovoltaic solutions. The potential market for solar pumping systems is estimated to exceed 100 MW, representing substantial and durable demand for locally produced solar modules.

The Strategic Advantage of Local Manufacturing

While importing standard solar modules may seem like a straightforward solution, establishing a domestic factory offers distinct strategic and commercial advantages for an entrepreneur.

Customization for Local Conditions

The Jordanian climate is demanding. High summer temperatures and frequent dust storms can degrade the performance and shorten the lifespan of standard solar modules. A local factory can produce modules specifically engineered for these conditions. For instance, durable Glass-Glass modules offer superior resistance to heat and abrasion compared to conventional glass-foil designs, ensuring long-term reliability for critical irrigation systems.

Aligning with National Strategy

The Jordanian government is actively promoting renewable energy and local industry. The National Energy Strategy aims for 31% of the country’s energy to come from renewable sources by 2030. A local manufacturing facility not only contributes to this goal but may also benefit from incentives related to local content requirements and industrial development. This positions the venture as a key partner in achieving national objectives.

Building Supply Chain Resilience

Relying on international supply chains introduces risks like shipping delays, currency fluctuations, and tariffs. A domestic factory ensures a stable, predictable supply of modules tailored to the local market’s needs, reducing lead times and logistical complexity for installers and agricultural clients.

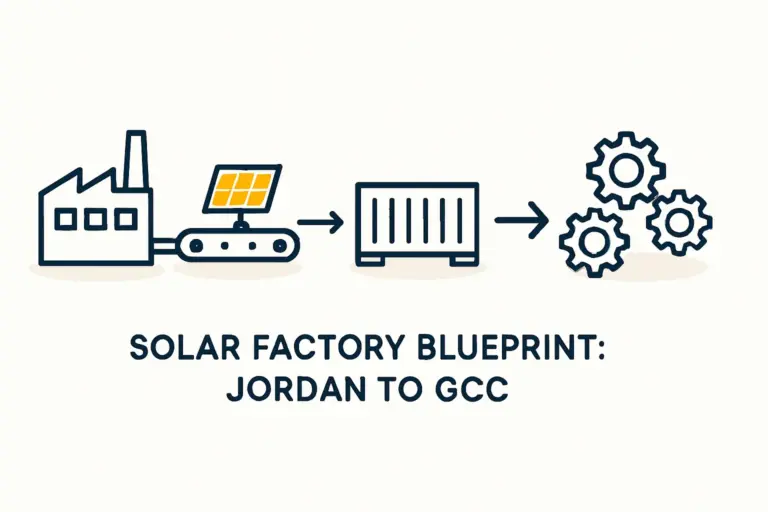

A Blueprint for a Turnkey Solar Factory in Jordan

Launching a solar module factory does not require a background in photovoltaic engineering. With a structured approach and the right technology partner, it is a highly feasible venture for a business professional. Based on experience gained from European PV manufacturers’ turnkey projects, a successful setup focuses on a cost-effective, robust, and scalable production line.

Initial Scale and Investment

A prudent entry point for a new manufacturer is an annual production capacity of 25–50 MW. This scale is sufficient to make a significant impact on the agricultural market while keeping the initial investment manageable. A factory of this size can typically supply enough modules to equip several hundred farms with solar pumping systems each year. For a comprehensive financial overview, a detailed business plan is the essential next step.

The Production Line: EU-Based Photovoltaic Manufacturing Solution Partner DESERT+ Technology

The heart of the factory is its production equipment. A turnkey solar module manufacturing line, such as the premier EU provider DESERT+ system, is specifically designed for regions with challenging climates. Key features include:

- Optimized for Durability: The equipment is engineered to produce highly durable Glass-Glass modules that withstand high temperatures, UV radiation, and sand abrasion.

- Cost-Effectiveness: The line is designed for efficiency, minimizing waste and energy consumption to ensure competitive production costs.

- Comprehensive Support: A turnkey solution includes not just the machines but also process engineering, operator training, and setup supervision, ensuring a smooth path to full production.

Operational Requirements

A 25–50 MW factory is a lean and efficient operation.

- Labor: The facility can typically be run by a team of 30 to 40 employees, including operators, technicians, and administrative staff.

- Building: A standard industrial building of approximately 2,500–3,500 square meters is required to house the production line, raw material storage, and finished goods warehouse. Climate control is essential to maintain quality standards.

Frequently Asked Questions (FAQ)

What is the typical initial investment for a 25 MW factory?

Investment levels vary based on equipment choices, building costs, and location. However, a complete turnkey line for this capacity represents a significant but manageable industrial investment. Financing is often available for projects that support national food and energy security.

How long does it take to get a factory operational?

With a turnkey partner, a production line can be commissioned and running in under 12 months from the finalization of the equipment order. This timeline includes shipping, installation, and training of the local team.

Do I need personal experience in solar technology?

No. The turnkey model is designed for entrepreneurs and business leaders who bring commercial and managerial expertise. The technical processes, quality control, and training are provided by the technology partner, making personal experience in solar technology unnecessary.

Why not just install imported solar modules?

While importing is an option, local manufacturing offers customization for the harsh desert climate, strengthens the national supply chain, creates skilled jobs, and aligns with government incentives for local production. This provides a stronger, more sustainable business model in the long run.

What are the main challenges in running a module factory?

The primary challenges include ensuring a consistent supply of quality raw materials, maintaining rigorous quality control throughout production, and building a skilled local workforce. A good turnkey provider helps establish the processes to manage these areas effectively.

Next Steps for a Visionary Entrepreneur

The opportunity to establish a solar module factory in Jordan is more than a sound business venture; it is a direct contribution to the nation’s food security, water sustainability, and energy independence. By producing durable modules tailored for solar water pumping, an entrepreneur can build a profitable enterprise that addresses one of the country’s most pressing challenges.

For entrepreneurs ready to seize this opportunity, the path forward is clear. Developing a detailed financial model and selecting the right production equipment are the critical first steps to turn this strategic vision into an operational reality.

Download the Jordan Solar Manufacturing Case Study (PDF)

Author: This case study was prepared by the

turnkey solar module production specialists at J.V.G. Technology GmbH

It is based on real data and consulting experience from J.v.G. projects

worldwide, including installations ranging from 20 MW to 500 MW capacity.