Imagine the final commissioning of a multi-million dollar solar module factory. The state-of-the-art equipment is calibrated, the staff is trained, and the first major production run is underway. Suddenly, the lights flicker and the entire facility goes silent. A grid failure, lasting several hours, not only halts production but also damages a batch of materials mid-process, resulting in significant financial loss.

This scenario is a critical operational risk for entrepreneurs in many regions, including Kenya. According to industry data, grid outages can average over 50 per year per customer in some areas. For a business reliant on continuous processes, this instability is more than an inconvenience; it’s a direct threat to profitability and viability. A 2019 World Bank report estimated that such power outages cost Kenyan businesses an average of 1.5% of their annual sales.

This article outlines the challenges of powering a sensitive manufacturing facility on an unstable grid and explores modern, reliable energy solutions that can secure a factory’s operations and financial future.

The High Cost of Unreliable Power in Manufacturing

The primary challenge of an unstable grid is not just the absence of power but its poor quality. It is estimated that up to 70% of Kenyan manufacturers are affected by power quality issues like voltage sags and surges. These fluctuations can be even more damaging than a complete blackout, causing gradual degradation or sudden failure of sophisticated electronic components.

For a business involved in solar module manufacturing, the stakes are particularly high. The process relies on a chain of sensitive machinery, from cell stringers to laminators, where precise temperature, pressure, and timing are paramount. A momentary power disruption can compromise an entire lamination cycle, rendering hundreds of modules worthless. The financial impact extends beyond lost materials to include production downtime, delayed shipments, and potential damage to capital equipment.

Establishing a reliable, independent power source is not an optional upgrade but a foundational requirement for business continuity.

Evaluating Traditional and Modern Power Solutions

Faced with an unreliable grid, many industrial operators default to a seemingly straightforward solution: diesel generators. While effective for backup power, they come with significant drawbacks:

-

High Operating Costs: The cost to run an industrial diesel generator in Kenya is typically between $0.25 and $0.40 per kWh, subject to volatile global fuel prices.

-

Maintenance Demands: Generators require regular, skilled maintenance, adding to operational overhead.

-

Environmental Impact: Emissions and noise pollution are growing concerns for both regulatory bodies and corporate social responsibility.

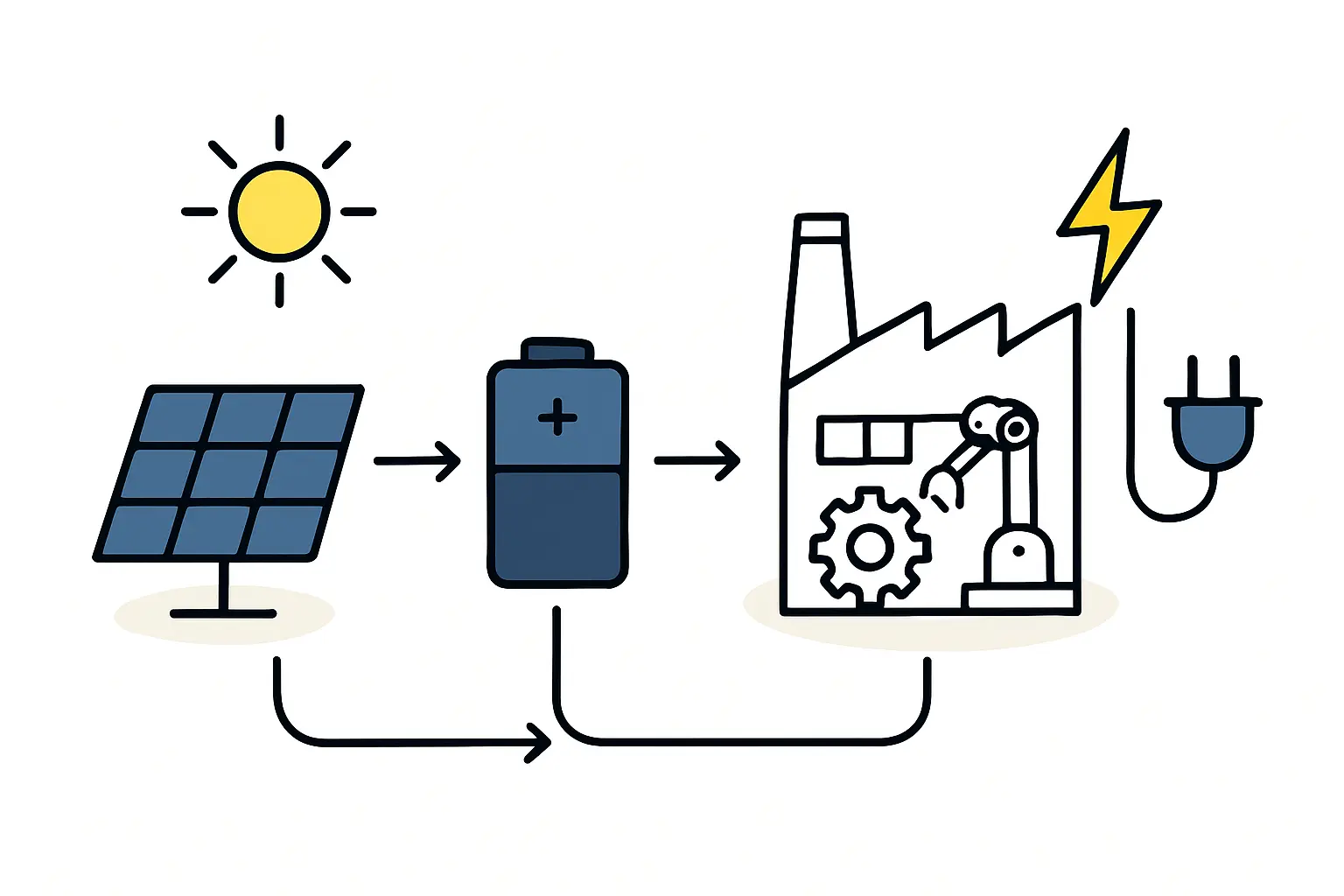

A more strategic and financially sustainable alternative is a captive hybrid power system designed specifically for the factory’s needs. This integrated solution typically combines three key components:

-

Solar Photovoltaic (PV) Array: Generates clean, low-cost electricity from sunlight during the day, directly powering the factory.

-

Battery Energy Storage System (BESS): Stores excess solar energy generated during the day and delivers it during the night or grid outages, ensuring a 24/7 power supply. It also acts as a buffer, providing clean, stable electricity and protecting equipment from grid fluctuations.

-

Backup Generator: A smaller generator can be included for redundancy, providing an additional layer of security during prolonged periods of bad weather or for exceptionally high power demands.

This hybrid approach shifts a factory from a state of energy vulnerability to one of independence and control.

The Business Case for a Solar-Plus-Storage System

While the initial capital investment for a hybrid system is higher than for a generator alone, the long-term financial analysis reveals a clear advantage. The key metric to consider is the Levelized Cost of Energy (LCOE), which represents the average total cost to build and operate a power source over its lifetime divided by its total energy output.

Recent data shows that the LCOE for commercial solar-plus-storage systems in Kenya can be as low as $0.12 – $0.18 per kWh. This is significantly lower than the ongoing cost of diesel fuel and, in many cases, competitive with or even cheaper than grid electricity, especially when the cost of downtime is factored in.

Market behavior confirms this trend: in 2022, the installation of commercial and industrial solar systems in Kenya grew by 62% as businesses increasingly recognized the economic benefits. For a new factory, integrating a captive power system from the outset protects the investment, ensures predictable operating expenses, and enhances the overall financial viability of the enterprise.

Key Considerations for System Design

Designing an effective hybrid power system is a precise engineering task that demands careful planning and is a critical component of setting up a turnkey production line. The process involves several key steps:

-

Conducting an Energy Load Analysis: The first step is to accurately map the factory’s electricity consumption. This includes understanding the peak power demand (the maximum amount of power needed at any one time) and the total daily energy usage (kWh). The analysis must account for all machinery, lighting, HVAC, and administrative office needs.

-

Sizing the System Components: Based on the load analysis and local solar irradiation data, engineers can determine the appropriate size for the solar array and battery bank. The goal is to generate enough energy to power operations during the day while storing sufficient excess to cover nighttime consumption and provide a buffer for several days of inclement weather.

-

Integration and Control: A sophisticated power management system is required to seamlessly switch between solar, battery, grid, and generator power. This controller is the “brain” of the system, ensuring the most cost-effective energy source is always in use and that the power delivered to the machinery is stable and within tight tolerances.

As experience from J.v.G. turnkey projects demonstrates, engaging with technical experts early in the factory planning phase is essential to ensure the power system is fully integrated with the building design and production layout.

Frequently Asked Questions About Factory Power Systems

How much space is required for a factory solar system?

The space required depends on the factory’s energy needs. As a general guideline, a 100-kilowatt (kW) solar array, often installed on a factory roof, requires approximately 600–800 square meters. Ground-mounted systems can also be an option if sufficient land is available.

Can a solar and battery system power a factory 24/7?

Yes. A properly sized system is designed for round-the-clock operation. The solar panels generate power during the day, and the battery energy storage system (BESS) discharges overnight or during grid outages. The system is engineered to provide full autonomy based on the facility’s specific load profile.

What is the typical payback period for such a system in a region like Kenya?

The payback period depends heavily on the cost of grid electricity and the price of the diesel fuel it replaces. For many commercial and industrial facilities in Kenya, the return on investment for a solar-plus-storage system is typically realized within 5 to 8 years, after which the electricity generated is virtually free.

Is this type of power system only for new factories?

No, a hybrid power system can be retrofitted to an existing facility. A thorough energy audit of the current operations would be the first step in designing a system to improve power reliability and reduce long-term energy costs.

Securing Your Investment with a Reliable Power Strategy

For any entrepreneur entering the capital-intensive field of solar module manufacturing, managing operational risk is fundamental. In regions with underdeveloped or unstable electrical infrastructure, the factory’s power supply system should be viewed not as a utility expense, but as a strategic asset that ensures uptime, protects equipment, and delivers predictable production costs.

By investing in a well-designed captive power system, a business leader can effectively insulate the facility from external grid failures, creating a stable and self-sufficient manufacturing environment poised for long-term growth and profitability.