An entrepreneur establishes a state-of-the-art solar module production line. With an efficient facility, a skilled team, and modules that have passed the rigorous International Electrotechnical Commission (IEC) tests—the global benchmark for quality and safety—it’s natural to assume the world is their market.

However, when they explore opportunities in a mature and lucrative market like South Korea, they encounter an unexpected hurdle. Their IEC certificates, while valuable, are not enough for market entry. They soon learn of a new set of requirements: Korean Industrial Standards (KS) and a mandatory carbon footprint certification. This scenario highlights a crucial lesson in the solar industry: global standards open doors, but local standards are the keys that unlock specific markets.

This guide breaks down the Korean Certification (KS) standards for solar modules, detailing the technical requirements, testing procedures, and unique environmental criteria essential for any manufacturer aiming to succeed in the South Korean domestic market.

What is Korean Certification (KS)?

Korean Certification, or the KS Mark, is a mandatory certification for solar modules sold in South Korea. Regulated by the Korean Agency for Technology and Standards (KATS) and administered by bodies like the Korea Energy Agency (KEA), the KS Mark signifies that a product not only meets performance and safety standards but also comes from a facility with consistent quality management systems.

For solar modules, the primary standards are:

-

KS C 8561: Largely based on the international IEC 61215 standard, this covers design qualification and type approval with a focus on performance.

-

KS C 8562: This standard addresses safety qualifications, mirroring the requirements of the international IEC 61730 standard.

Obtaining KS certification is a non-negotiable prerequisite for participating in government-led projects and selling to the broader South Korean market. It serves as both a quality assurance measure and a form of market regulation.

How KS Standards Relate to International IEC Norms

For professionals new to the industry, understanding the relationship between KS and IEC is fundamental. While KS standards are harmonized with IEC norms, they are not identical. A manufacturer with existing IEC certificates cannot simply use them to gain KS approval.

The core difference lies in the process and scope. IEC certification validates the design and safety of a module type through testing at an accredited laboratory. KS certification, on the other hand, goes further by mandating:

-

A comprehensive factory audit: Korean auditors conduct an on-site inspection of the production facility to verify that its quality control processes and manufacturing systems can consistently produce modules that meet KS specifications.

-

Specific local requirements: The KS standards include additions and deviations from the IEC baseline to address criteria specific to the Korean market.

-

A mandatory Carbon Footprint Certification: This is perhaps the most significant distinction and a considerable barrier for new entrants.

So, while the technical testing for performance and safety is similar, the KS process is an independent, more holistic evaluation of both the product and the production environment. This is a key part of the overall solar panel certification landscape that manufacturers must navigate.

The Carbon Footprint Certification: A Unique Market Barrier

South Korea has implemented a Carbon Footprint Certification system for solar modules as part of its renewable energy policy. This system requires manufacturers to quantify the total carbon dioxide (CO2) emissions generated during a module’s entire production process, measured in kilograms of CO2 equivalent per kilowatt-peak (kg CO2-eq/kWp).

The calculation covers every stage, from raw material extraction to final assembly:

-

Polysilicon production

-

Ingot and wafer manufacturing

-

Solar cell production

-

Module assembly

The final carbon footprint score places a module into one of three tiers, directly impacting its marketability and eligibility for government incentives. Modules with lower carbon footprints receive preferential treatment, while those in the highest tier may be effectively excluded from the market.

This requirement presents a significant challenge for manufacturers outside Korea, as it necessitates detailed supply chain data that can be difficult to obtain and verify. Entrepreneurs planning to enter this market must integrate carbon accounting into their operational strategy from the outset.

Key Technical Requirements and Testing Procedures

The KS certification process involves a series of rigorous tests that largely mirror those in IEC 61215 and IEC 61730. The objective is to ensure long-term performance, reliability, and safety under various environmental conditions.

Module Performance and Durability Testing (KS C 8561)

These tests are designed to simulate the stresses a module will face over its operational lifetime. Key procedures include:

-

Thermal Cycling Test: Subjects the module to extreme temperature fluctuations to test the integrity of solder joints and interconnections.

-

Damp Heat Test: The module is exposed to high temperature and humidity for an extended period (typically 1,000 hours) to test its resistance to moisture ingress and corrosion.

-

UV Preconditioning Test: This test simulates long-term sun exposure to check for degradation in encapsulation materials.

-

Mechanical Load Test: Applies pressure to the front and back of the module to ensure it can withstand wind and snow loads.

Safety Testing (KS C 8562)

Safety tests confirm that the module is electrically and mechanically safe for installers and end-users. This includes:

-

Insulation Resistance and Wet Leakage Current Tests: Verify that the module is properly insulated to prevent electrical shocks, especially in wet conditions.

-

Fire Resistance Test: Evaluates the module’s flammability and its potential to contribute to the spread of a fire, a critical factor for building-integrated PV (BIPV) systems.

Meeting these standards consistently means the entire solar panel manufacturing process must be optimized, as the factory audit will scrutinize every step from material reception to final packaging.

The KS Certification Process: A Step-by-Step Overview

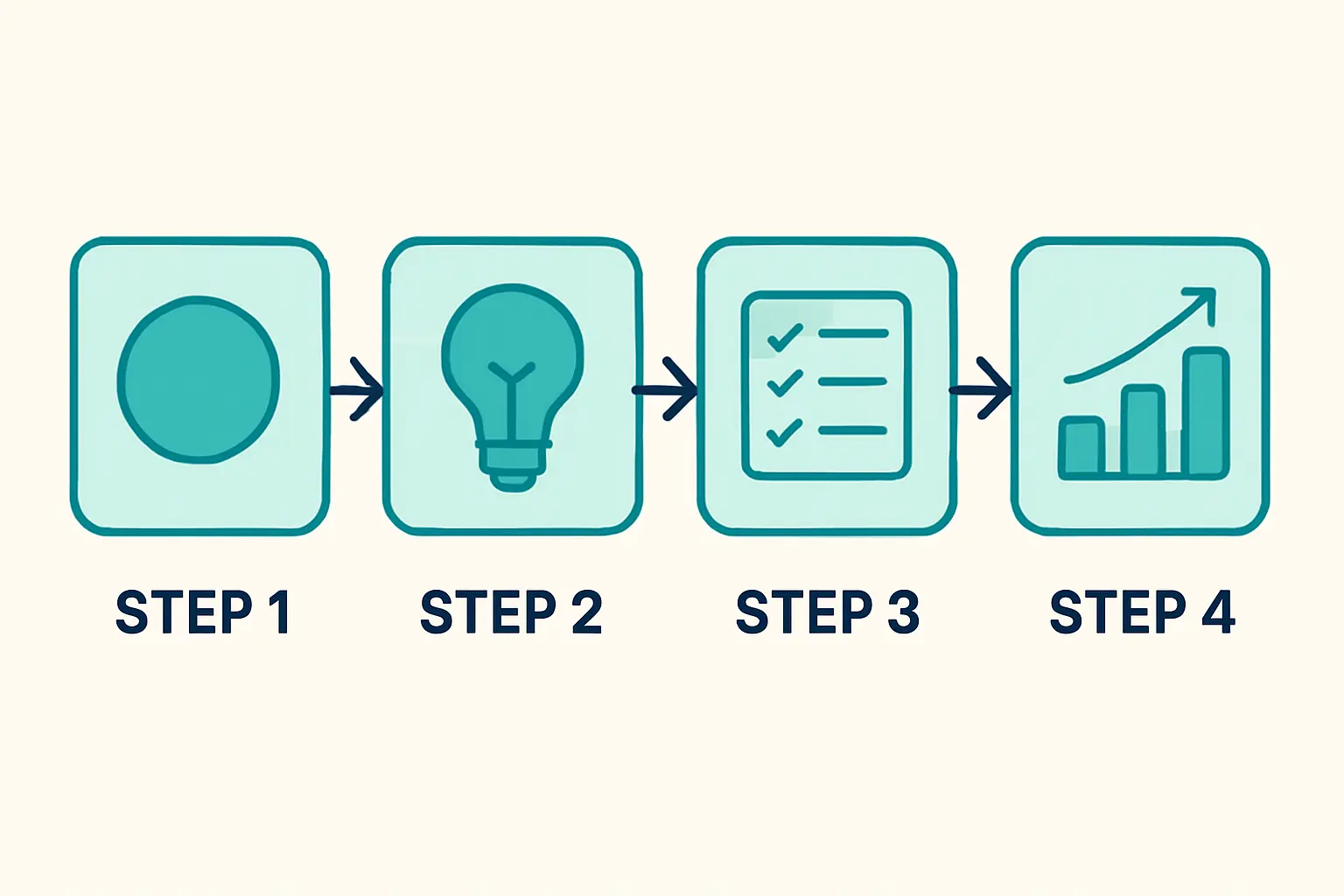

For any business professional, understanding the certification journey is essential for planning timelines and resources. While specifics can vary, the process generally follows these steps.

-

Application and Documentation: The manufacturer submits a formal application to a designated Korean certification body, along with extensive technical documentation on the module design, bill of materials (BOM), and the factory’s quality management system.

-

Factory Audit: The Korean certification body dispatches auditors to the manufacturing facility. This on-site inspection verifies that the production line, quality control procedures, and documentation align with KS requirements.

-

Sample Selection and Testing: Auditors select sample modules directly from the production line for testing. These samples are sent to an accredited laboratory in Korea to undergo the full suite of KS C 8561 and KS C 8562 tests.

-

Certification Decision: If the factory audit is successful and the modules pass all tests, the certification body issues the KS certificate.

-

Post-Certification Surveillance: KS certification is not a one-time event. The manufacturer is subject to regular follow-up factory audits (typically annually) and product testing to ensure ongoing compliance.

Based on experience from J.v.G. turnkey projects, the entire process—from application to certification—can take anywhere from six months to over a year, depending on the manufacturer’s readiness and the certification body’s schedule.

Frequently Asked Questions (FAQ) about KS Certification

How long does the KS certification process typically take?

The comprehensive process generally takes 6 to 12 months, a timeline that accounts for application review, factory audit scheduling, sample shipping, and the full duration of the required tests.

Is KS certification a one-time process?

No. To maintain the KS Mark, manufacturers must undergo regular surveillance audits of their factory and periodic product re-testing to ensure quality standards are consistently met.

Can an existing IEC certification be used to skip KS tests?

No. While the test standards are similar, KS certification requires that all tests be conducted independently for the KS application. An existing IEC certificate is beneficial, as it indicates a high likelihood of passing KS tests, but it does not grant an exemption.

What are the main costs associated with KS certification?

The primary costs include application fees, factory audit fees (including travel and accommodation for auditors), module testing fees at the Korean laboratory, and the cost of the sample modules. There are also internal costs for preparing the factory and documentation for the audit.

Next Steps for Market Entry

Entering a highly regulated and competitive market like South Korea requires more than just a quality product. It demands a deep understanding of the local certification landscape, a commitment to transparent manufacturing processes, and strategic planning from the outset.

The KS certification and its unique carbon footprint requirement are a clear reminder that a successful global solar business must be adaptable and well-informed. For entrepreneurs planning their market entry, treating certification not as a final hurdle but as an integral part of the business model is the first step toward success. A thorough grasp of these requirements is essential when learning how to start a solar panel factory with international ambitions.