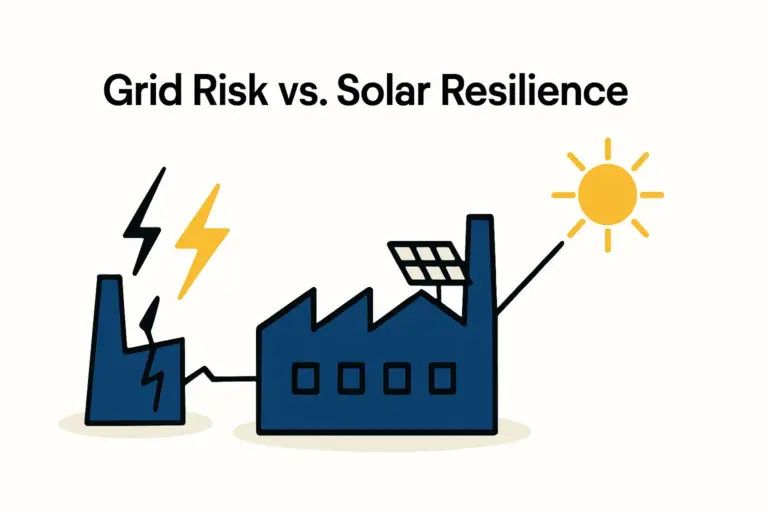

Kosovo stands at an energy crossroads. Blessed with abundant sunshine yet reliant on lignite coal for over 95% of its electricity, the nation faces both a pressing challenge and a significant opportunity.

As the government commits to a greener future, targeting 600 MW of solar capacity by 2031, a compelling question arises for entrepreneurs and investors: Is now the time to establish local solar module manufacturing?

While the idea of a large-scale factory may seem daunting, a focused, smaller-scale approach presents a pragmatic and potentially lucrative entry into this growing market. This analysis makes the case for a 20-50 MW solar module assembly line designed to meet Kosovo’s emerging domestic demand.

The Strategic Context: Why Solar Manufacturing in Kosovo Makes Sense Now

The momentum for solar energy in Kosovo stems from a combination of economic, environmental, and political factors. Decades of dependence on coal have led to significant air pollution, particularly in urban centers like Pristina during winter. This public health concern, coupled with international commitments under the Energy Community Treaty, creates powerful momentum for change.

The government has responded with a clear strategy. The National Energy and Climate Plan (NECP) is not merely a document of intent; it is a roadmap with specific, bankable targets. This goal of adding 600 MW of solar power creates a predictable, long-term domestic market. Furthermore, initiatives like the announced 150 MW solar auction signal that state support is translating into tangible projects that will require a steady supply of solar modules.

For a local entrepreneur, this alignment of policy and need minimizes market entry risk. The demand isn’t speculative—it’s mandated by national policy and driven by urgent energy needs.

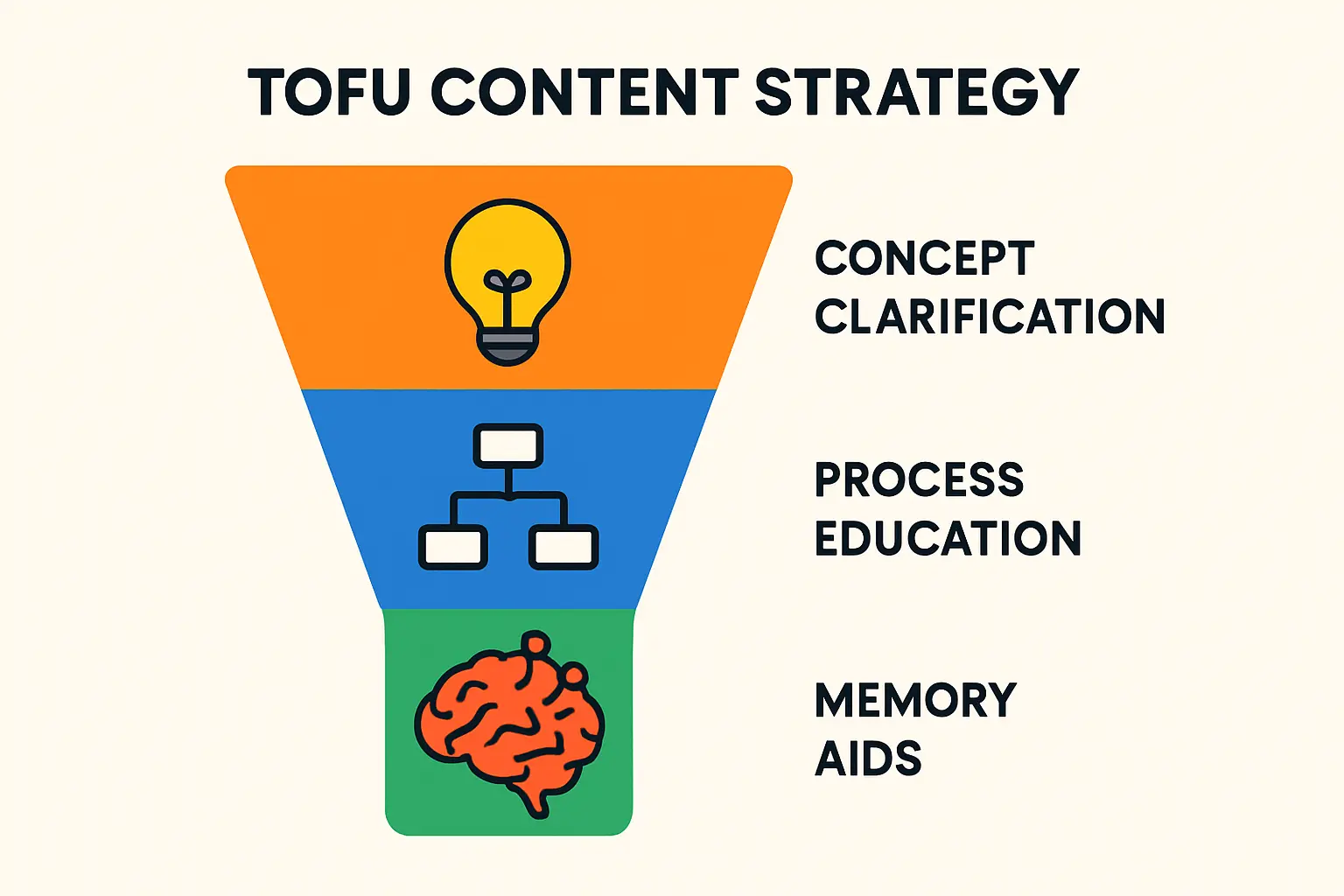

The Small-Scale Advantage: A Pragmatic Entry Strategy

The global solar industry is often associated with massive ‘gigafactories’. For a nascent market like Kosovo, however, a 20-50 MW facility offers distinct advantages better suited to the immediate landscape.

Lower Capital Expenditure

The primary barrier to entry in manufacturing is the initial investment. A 20-50 MW semi-automated line requires a significantly lower financial commitment than a fully automated, export-focused plant. This makes the project more accessible to local or regional investors and simplifies securing financing. The capital investment required is manageable, allowing a quicker path to profitability by serving the first waves of domestic projects.

Focus on Domestic Demand

Instead of competing with global manufacturing giants on the international stage, a local factory can concentrate on serving developers, installers, and government tenders within Kosovo. This focus eliminates complex export logistics, currency exchange risks, and the need to navigate international trade policies. The facility can become a key part of the national energy infrastructure.

Faster Implementation

Smaller projects inherently mean shorter timelines. Based on experience from J.v.G. turnkey projects, a well-planned 20-50 MW facility can move from a final investment decision to full production in just 9 to 12 months. This speed allows an investor to capitalize on the current policy window and begin supplying modules for the first large-scale solar projects.

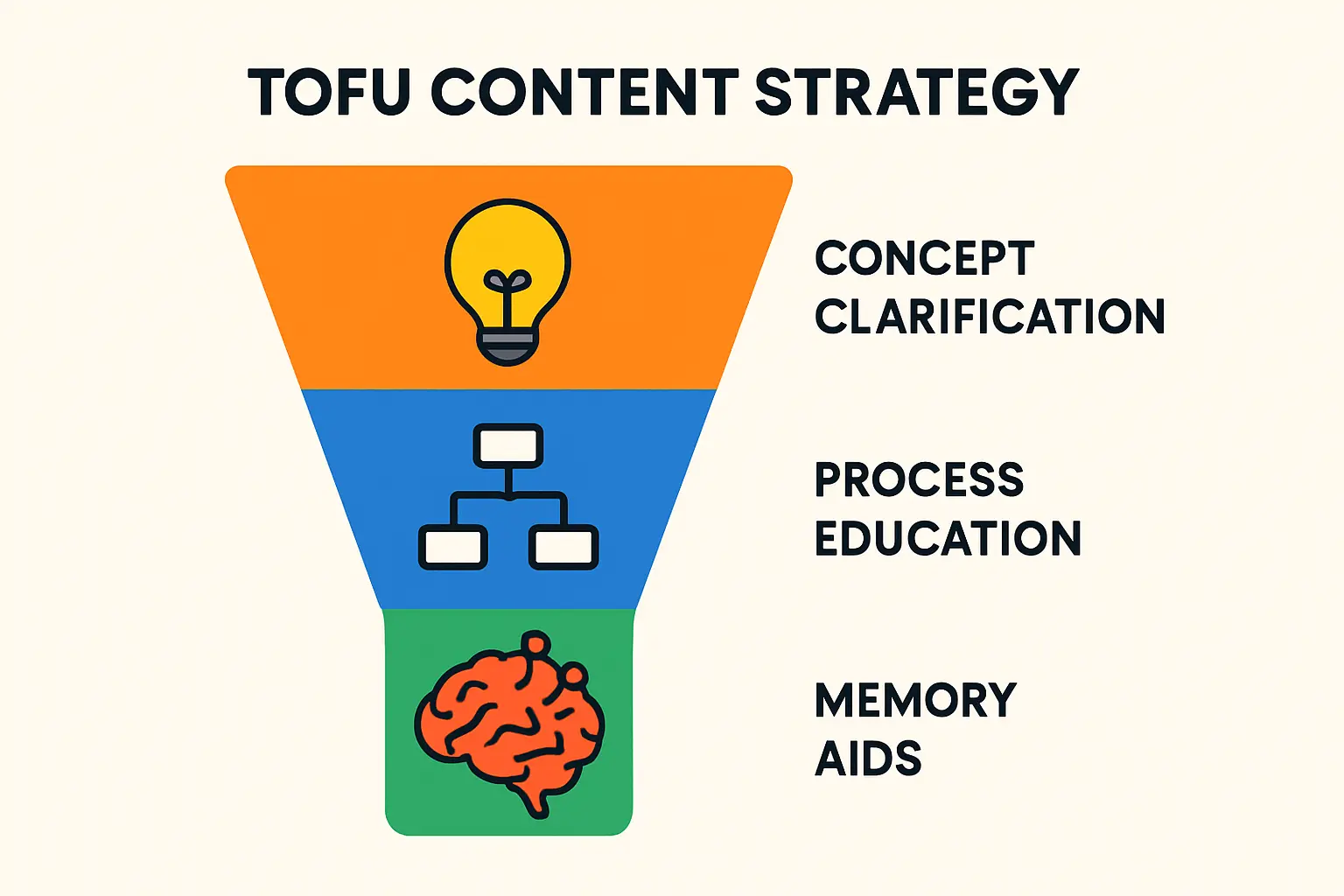

Understanding the Production Process for a 20-50 MW Line

It’s a common misconception that manufacturing a solar panel is an exceedingly complex process. In reality, a module production line is an advanced assembly operation. The core components—solar cells, glass, encapsulant, and backsheets—are sourced from specialized global suppliers. The factory’s role is to assemble these materials into a durable, high-performance final product.

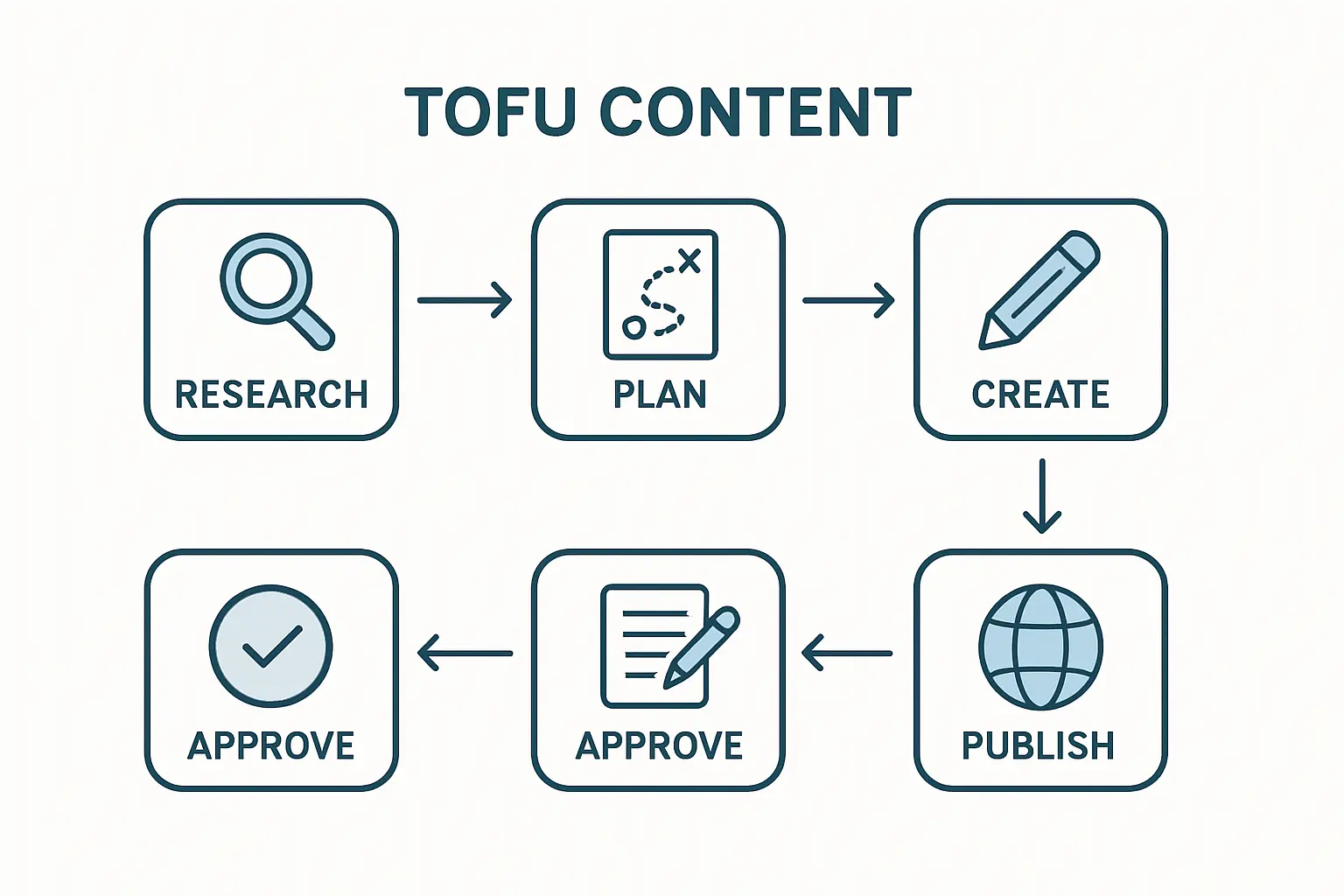

The complete solar panel manufacturing process involves several key stages:

-

Cell Stringing: Solar cells are soldered together into ribbons, or ‘strings’.

-

Layup: The strings are precisely placed between layers of glass, encapsulant, and a protective backsheet.

-

Lamination: This ‘sandwich’ is heated and vacuum-sealed in a laminator to create a durable, weatherproof unit.

-

Framing and Junction Box Installation: An aluminum frame is added for structural integrity, and a junction box is attached for electrical connections.

-

Testing: Each finished module undergoes rigorous testing to ensure it meets power output and quality standards.

A semi-automated line for a 20-50 MW facility balances sophisticated machinery with skilled human oversight. This approach optimizes the investment in essential machinery while creating valuable local jobs.

Aligning with National Goals and Market Realities

A local solar module factory is more than a business venture—it’s a strategic asset for Kosovo’s economy and energy independence.

A facility producing 50 MW of modules annually could directly supply over 8% of the country’s total 600 MW solar target over a decade. This would make it a critical partner for the government as it works to achieve its renewable energy objectives.

The benefits extend beyond energy policy:

- Supply Chain Security: Reduces dependence on imported modules, insulating projects from global shipping delays and price volatility.

- Job Creation: Creates skilled technical and operational jobs, contributing to local economic development.

- Quality Control: Allows for direct oversight of module quality, ensuring panels are optimized for Kosovo’s specific climate conditions.

- National Pride: Establishes a ‘Made in Kosovo’ brand in a high-tech, future-oriented industry.

While challenges like land acquisition and grid integration for large solar farms remain, a local module manufacturer is in a prime position to work with project developers and government agencies to overcome these hurdles.

Frequently Asked Questions (FAQ) for Aspiring Solar Entrepreneurs

What is a realistic timeline to start a 20-50 MW factory?

With a structured approach and an experienced technical partner, a timeline of 9 to 12 months from financing to the start of production is realistic. Engaging a provider for a turnkey solar production line can significantly streamline this process.

Do I need a deep technical background in photovoltaics?

While technical curiosity helps, a strong business and project management background is more critical. The technical complexities of process engineering, machine selection, and quality control can be handled by partnering with experienced consultants and hiring a qualified operational team. The pvknowhow.com platform provides structured e-courses to help bridge this knowledge gap for business professionals.

What kind of building is required for a small-scale line?

A typical 20-50 MW assembly line requires an industrial building of approximately 2,000 to 3,000 square meters. Key requirements include a ceiling height of at least 6 meters, a reinforced concrete floor capable of bearing machine loads, and a climate-controlled environment to protect sensitive materials.

How can a local factory compete with large international suppliers?

A local factory competes on agility, not scale. Its competitive advantages lie in faster delivery for domestic projects, custom module specifications, and local technical support. It also eliminates international freight costs and import duties.

Conclusion: Your Next Steps in Evaluating the Opportunity

Kosovo’s transition to renewable energy is underway, creating a defined, durable market for solar modules. For the discerning investor, a 20-50 MW solar module assembly line represents a strategic entry point that is financially sound, operationally achievable, and perfectly aligned with national priorities.

This model mitigates the high capital risks of a gigafactory while positioning the venture to become a cornerstone of Kosovo’s clean energy future. The next step is to move from this high-level assessment to a detailed financial and operational plan that specifies the required machinery, raw materials, and facility layout.