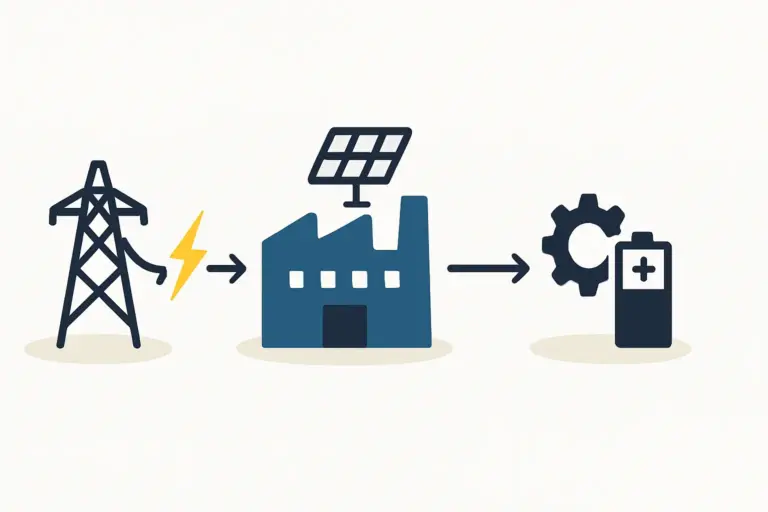

While discussions around launching a solar module factory often focus on machinery and capital, experienced investors know that long-term success hinges on human capital. In a market like Kyrgyzstan, where industrial manufacturing is developing, a detailed analysis of labor costs and skill availability isn’t just a preliminary step—it’s the cornerstone of a viable business plan. An entrepreneur might secure the finest equipment, but without the right team to operate and maintain it, the facility’s potential will remain unrealized.

This analysis outlines the typical workforce requirements, salary benchmarks, and training strategies for establishing a 20–50 MW solar module production facility in Kyrgyzstan. It offers a realistic framework for investors and project developers planning to enter this promising sector.

Structuring the Workforce for a 20–50 MW Production Line

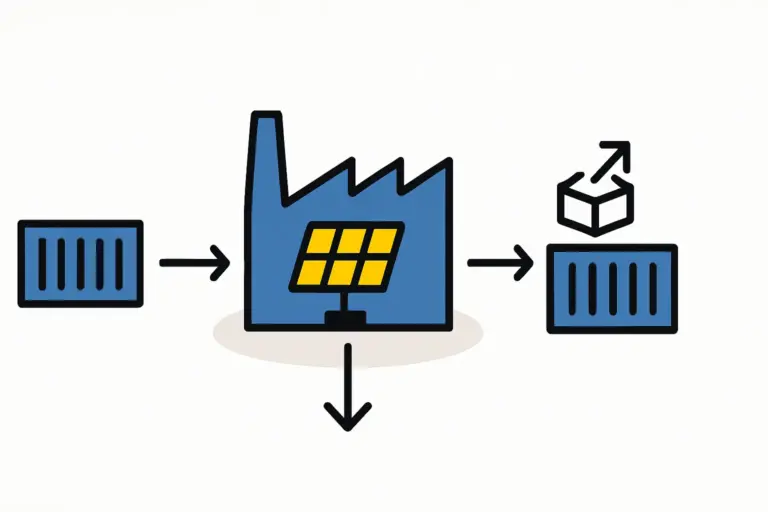

A modern, semi-automated solar module factory doesn’t require a vast workforce. Instead, its efficiency depends on process optimization and well-trained personnel. For a facility operating two shifts to produce between 20 and 50 MW annually, a team of approximately 25 to 30 employees is a standard benchmark.

The team is typically divided into three core groups: management and administration, technical staff, and production operators. Each has distinct responsibilities critical to the factory’s daily operations and strategic growth.

Management and Administrative Staff

This core team oversees the entire operation, ensuring production targets, quality standards, and financial goals are met.

- General Manager (1): Responsible for overall business strategy, financial management, and stakeholder relations.

- Production Manager (1): Manages day-to-day factory operations, production scheduling, and workflow efficiency.

- Logistics & Procurement Officer (1): Handles the supply chain, from raw material procurement to finished goods shipment.

Technical and Engineering Staff

This group forms the technical backbone of the factory. Their expertise ensures the machinery runs optimally and the final product meets international standards.

- Quality Control (QC) Engineer (1): Monitors all production stages to ensure compliance with quality certifications.

- Maintenance Engineer (1): Responsible for the preventative maintenance and repair of all essential solar manufacturing machines.

- Shift Leaders (2): Supervises the production teams on each shift, ensuring safety and productivity.

Production and Operator Staff

These hands-on personnel operate the machinery and assemble the solar modules. A typical two-shift operation would require:

- Machine Operators (12-16): Trained specialists for key stations like the stringer, laminator, and solar simulator.

- General Production Workers (4-6): Support various stages, including material preparation, framing, and packaging.

- Warehouse Staff (2): Manages inventory of raw materials and finished products.

Labor Cost Analysis in the Kyrgyz Context

Understanding local wage structures is fundamental to creating an accurate financial forecast. The following table, based on current economic data for Kyrgyzstan, provides estimated monthly net salary ranges. These figures are illustrative and can vary with a candidate’s experience and the specific location. They are presented in USD for international comparison.

| Position | Estimated Monthly Net Salary (USD) | Number of Positions | Total Monthly Cost (USD) |

|---|---|---|---|

| General Manager | $1,500 – $2,500 | 1 | $1,500 – $2,500 |

| Production Manager | $1,000 – $1,500 | 1 | $1,000 – $1,500 |

| QC Engineer | $800 – $1,200 | 1 | $800 – $1,200 |

| Maintenance Engineer | $800 – $1,200 | 1 | $800 – $1,200 |

| Shift Leader | $500 – $700 | 2 | $1,000 – $1,400 |

| Logistics Officer | $500 – $700 | 1 | $500 – $700 |

| Machine Operator | $350 – $450 | 14 | $4,900 – $6,300 |

| General Production Worker | $300 – $400 | 4 | $1,200 – $1,600 |

| Warehouse Staff | $300 – $400 | 2 | $600 – $800 |

| Total (Approx. 27 Staff) | $12,300 – $17,200 |

This projection places the estimated annual labor expenditure at approximately $147,600 to $206,400. As a significant component of overall operational costs, this figure must be factored into the initial investment requirements. Notably, these costs are considerably lower than in developed economies, presenting a competitive advantage for manufacturing in the region.

The Critical Role of a Training Strategy

While Kyrgyzstan has a workforce with a solid foundation in general industrial skills, specific experience in photovoltaic manufacturing is rare. A new factory venture cannot, therefore, rely solely on finding ‘plug-and-play’ employees. Instead, a robust, structured training program is an essential investment.

The most effective approach involves training provided directly by the equipment supplier or a turnkey solutions partner. Based on experience from turnkey projects, this process typically includes:

- Classroom Instruction: Key personnel, especially engineers and shift leaders, receive theoretical training on solar cell technology, module composition, and quality control principles.

- On-the-Job Training: The supplier’s technicians provide hands-on instruction for every machine in the turnkey solar module production line. Operators learn the specific parameters, safety protocols, and basic maintenance for their designated station.

- Process Optimization: After initial training, experts remain on-site to help the new team ramp up production, troubleshoot early challenges, and optimize workflow for maximum efficiency.

This investment in training accomplishes two goals: it ensures expensive machinery is operated correctly and safely, and it develops a skilled local workforce—creating a sustainable operational asset for the long term.

Frequently Asked Questions (FAQ)

What are the most critical roles to hire first?

The first hires should be the General Manager, Production Manager, and Maintenance Engineer. This core team can then help set up the factory building and layout specifications, oversee machine installation, and help recruit the remaining staff.

Is it better to hire experienced staff from abroad or train local talent?

For key leadership or highly technical roles like the Maintenance Engineer, hiring an expatriate for an initial period can be beneficial. However, the most sustainable and cost-effective long-term strategy is to train local talent. A combination often works best: a few external experts to lead the setup and train a fully local team that will manage operations independently.

How long does a typical training program take?

A comprehensive training program for a new factory team typically lasts between four and six weeks. This includes initial classroom sessions and the hands-on training during the commissioning and ramp-up phases of the production line.

Do these labor costs include social contributions and taxes?

The salary figures provided are estimated net wages (take-home pay). Employers must budget for additional costs, including social security contributions, payroll taxes, and other mandatory benefits as required by Kyrgyz labor law. These can add a significant percentage, often 20–30 percent, to the total labor cost.

Conclusion: Planning for People is Planning for Profit

Establishing a solar module factory in Kyrgyzstan offers a compelling business opportunity, driven by growing regional demand and a favorable cost environment. However, success is not guaranteed by technology alone. A thoughtful human resources strategy—encompassing a clear organizational structure, a realistic budget, and a commitment to training—transforms a collection of machines into a productive and profitable enterprise.

By viewing labor not as a mere expense but as a strategic investment, entrepreneurs can build a capable, motivated team that serves as the foundation for sustainable growth and market leadership.