Disclaimer: This case study represents a composite example derived from real-world

consulting work by J.v.G. Technology GmbH in solar module production and factory optimization. All data points are realistic but simplified for clarity and educational purposes.

For business owners across Lebanon, daily reality is shaped by an unreliable national grid. The hum of a diesel generator is the soundtrack to commerce, a costly and unsustainable solution to a systemic energy deficit. This challenge, however, presents a strategic opportunity: localizing the production of a critical component for energy independence—the solar module.

The commercial and industrial (C&I) sector, the backbone of Lebanon’s economy, is actively seeking stable, long-term energy solutions. This has created immense demand for high-quality solar installations. While importing modules is the current norm, establishing a local production facility offers a more resilient and profitable path forward.

This document presents a business case for launching a 50 MW solar module production line in Lebanon, tailored to serve the nation’s growing C&I market. Understanding how to start a solar panel manufacturing business (https://www.pvknowhow.com/how-to-start-a-solar-panel-manufacturing-business) is the first step toward capitalizing on this unique opportunity.

The Market Opportunity: Why Local Manufacturing in Lebanon Is Viable

Lebanon’s energy landscape is defined by a severe electricity crisis, forcing businesses to rely on expensive private generators. The crisis has accelerated the adoption of solar power not as a luxury, but as an economic necessity. The market is projected to grow to 1,500 MW by 2030, driven almost entirely by the private sector.

Key Drivers for a Local Factory:

-

C&I Sector Demand: Factories, hospitals, shopping centers, and agricultural businesses are the primary consumers of solar energy. They require reliable, high-output modules to power their operations and reduce dependency on diesel. A local factory can cater directly to their specific needs.

-

Supply Chain Control: Importing solar modules involves navigating logistical complexities, currency fluctuations, and potential shipping delays. Local production provides greater control over the supply chain, ensuring timely delivery and price stability for large-scale projects.

-

Economic Resilience: A domestic manufacturing facility creates skilled jobs, retains capital within the country, and builds national industrial capacity. It positions the business as a key player in Lebanon’s energy transition.

-

Reduced Import Dependency: By producing modules locally, a business can mitigate risks associated with international trade policies and global supply chain disruptions, offering a more secure product source for Lebanese installers and project developers.

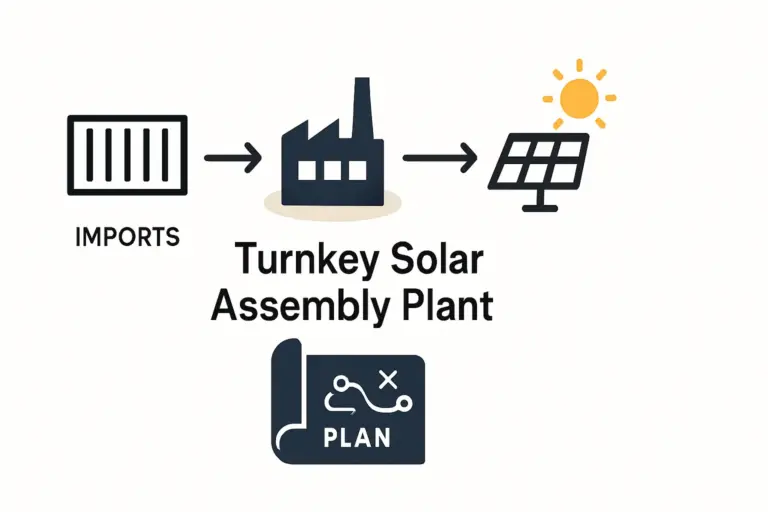

The Business Plan: A 50 MW Turnkey Solar Module Production Line

A 50 MW annual capacity represents a strategic entry point. It is large enough to achieve economies of scale and serve significant C&I projects, yet manageable for an entrepreneur entering the solar manufacturing space.

Investment Overview

Establishing a turnkey production line involves a structured investment in machinery, infrastructure, and operational capital. Based on data from similar expert-led European solar project architecture and modeling projects, the financial requirements are as follows:

-

Machinery & Equipment: This is the core investment, encompassing all stations from cell stringing to final testing. A complete solar panel manufacturing machine list (https://www.pvknowhow.com/solar-panel-manufacturing-machine-list) for a 50 MW line typically requires an investment of approximately €3.5 to €4.5 million, which covers high-quality, reliable equipment engineered for durability.

-

Building & Infrastructure: A suitable facility requires around 2,500 to 3,000 square meters of floor space with specific requirements for ceiling height, floor loading, and clean environments. The cost will vary based on whether the building is leased or constructed.

-

Working Capital: This covers the initial procurement of raw materials (solar cells, glass, EVA, backsheets, frames), operational expenses, and staff salaries for the first few months. A typical budget for initial working capital is around €1.0 to €1.5 million.

-

Total Estimated Initial Investment: Approximately €4.5 to €6.0 million, excluding building acquisition costs.

Operational Framework

-

Production Capacity: A 50 MW line, operating on a two-shift basis, can produce approximately 220–250 modules per day, or around 65,000 modules per year (assuming an average module power of 750Wp).

-

Staffing Requirements: An efficient facility requires a team of 45 to 55 employees, including production operators, quality control technicians, maintenance staff, and administrative personnel.

-

Project Timeline: With an experienced partner, the entire setup—from planning and procurement to installation and commissioning—can be completed within 10 to 12 months.

The Product: The DESERT+ Module for Lebanon’s Climate

Standard solar modules are not universally suitable. Lebanon’s climate, characterized by high summer temperatures, intense solar irradiation, and airborne dust, demands a specialized product. The DESERT+ module is specifically engineered for these conditions.

Why the DESERT+ Module Is the Ideal Product:

-

High-Temperature Performance: These modules are designed with a low temperature coefficient, meaning they lose less power as temperatures rise and ensure a higher energy yield during Lebanon’s hot summer months.

-

Bifacial Technology: DESERT+ modules capture sunlight from both sides. This feature can increase energy yield by up to 25%, especially when installed on reflective surfaces common in commercial rooftops or ground-mounted C&I projects.

-

PID Resistance: Potential-Induced Degradation (PID) is a significant cause of power loss in hot and humid environments. The materials used in DESERT+ modules are certified PID-resistant, guaranteeing long-term performance and investor security.

-

Durable Construction: A robust frame and strong glass make the module resilient to physical stresses, including wind and dust accumulation, ensuring a longer operational lifespan.

Producing a module specifically designed for the local environment provides a powerful competitive advantage over generic imported alternatives.

The Partner: EU-based Photovoltaic Manufacturing Solution Provider’s Turnkey Implementation

For entrepreneurs without a background in photovoltaics, the technical complexity of setting up a factory can seem daunting. That’s where an experienced implementation partner becomes essential. An experienced European turnkey engineering team with decades of experience, specializes in establishing turnkey solar manufacturing lines (https://www.pvknowhow.com/turnkey-solar-manufacturing-lines) globally.

A turnkey partner manages the entire project lifecycle, from business concept to fully operational factory. This includes:

-

Factory Layout & Process Design: Designing an efficient production flow tailored to the building and capacity goals.

-

Machine Sourcing & Integration: Selecting, procuring, and commissioning the right equipment from reliable suppliers.

-

Training & Know-How Transfer: Training the local workforce on machine operation, quality control protocols, and maintenance procedures. This approach has proven successful in numerous projects, enabling entrepreneurs like Mr. Goyal in India to establish thriving manufacturing plants without prior solar experience.

-

Material Sourcing & Certification: Assisting in establishing a reliable supply chain for raw materials and guiding the factory through international certification processes (e.g., IEC).

The pvknowhow.com platform complements this partnership with structured educational resources, allowing business leaders to understand the process before committing significant capital.

Frequently Asked Questions (FAQ)

-

How long does it take to start production?

From the final investment decision and signing of contracts, a 50 MW factory can typically be fully commissioned and ready for production in 10 to 12 months. -

What kind of workforce skills are required?

The majority of the production staff can be trained on the job. Key positions that require specific skills include a production manager with industrial experience, quality control technicians, and an electromechanical maintenance engineer. -

Can the factory’s capacity be expanded later?

Yes. The initial factory layout can be designed with future expansion in mind. A 50 MW line can often be upgraded to 100 MW or more by adding parallel machines without requiring a complete redesign of the facility. -

What are the primary raw materials needed?

The main components are solar cells, tempered glass, encapsulant film (EVA or POE), backsheets (or a second pane of glass for bifacial modules), aluminum frames, and junction boxes. A turnkey partner helps establish supply channels for these materials. -

How does local production offer a competitive advantage over importing?

Local production offers faster delivery times, customization for local project needs, elimination of import tariffs and shipping costs, and the ability to market a ‘Made in Lebanon’ product. This builds trust and ensures a stable supply for local installers.

Next Steps

Establishing a solar module factory in Lebanon is a direct and strategic response to the country’s energy crisis. It aligns a sound business investment with a critical national need, offering a clear path to profitability while contributing to a more resilient economic future.

The C&I sector is ready for a local, high-quality solution, and a 50 MW production line equipped to build specialized modules like the DESERT+ is well-positioned to meet that demand.

For professionals exploring this venture, the next step is to deepen your understanding of the technical, financial, and operational requirements. A structured approach, guided by experienced partners, can de-risk the process and ensure a successful market entry.

Download the 50 MW Lebanon Solar Case Study (PDF)

Author: This case study was prepared by the

turnkey solar module production specialists at J.V.G. Technology GmbH

It is based on real data and consulting experience from J.v.G. projects

worldwide, including installations ranging from 20 MW to 500 MW capacity.