Disclaimer: This case study represents a composite example derived from real-world

consulting work by J.v.G. Technology GmbH in solar module production and factory optimization. All data points are realistic but simplified for clarity and educational purposes.

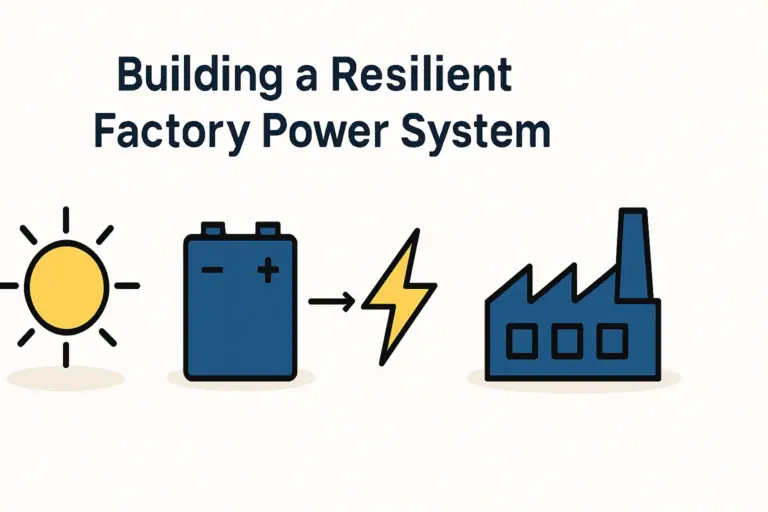

The persistent hum of private diesel generators has become the unfortunate soundtrack to daily life and business in Lebanon. For entrepreneurs, this sound represents more than an inconvenience; it signifies a monumental market failure and a significant commercial opportunity.

While the national grid struggles, the country has seen an unprecedented surge in private solar energy adoption, with an estimated 1,500 MW installed since 2020. This demand, however, is being met almost exclusively by imported solar modules, leaving businesses vulnerable to volatile supply chains, currency fluctuations, and inconsistent product quality.

This article outlines a strategic blueprint for entrepreneurs to tap into this growing market by establishing a local, 20 MW solar module assembly facility. It presents a lower-investment, high-impact model for entering the renewable energy sector, building a national brand, and contributing to Lebanon’s energy resilience.

Understanding the Market Driver: Lebanon’s Energy Deficit

Grasping the scale of the opportunity starts with understanding the structural problems driving it. Lebanon’s reliance on imported fossil fuels, which account for over 80% of its energy, has been a long-standing economic drain. The failure of the state utility, Electricité du Liban (EdL), to provide consistent power has forced residents and businesses onto costly and polluting private generators.

This environment has catalyzed a powerful, grassroots shift toward energy independence. The solar market’s growth of over 470% in 2022 alone is no fleeting trend but a fundamental response to a critical need. This demand presents a clear opening for local manufacturing to displace foreign imports. A local assembly plant can offer superior logistics, quality assurance, and a product tailored to the specific needs of the Lebanese market.

Why Local Assembly is the Strategic Entry Point

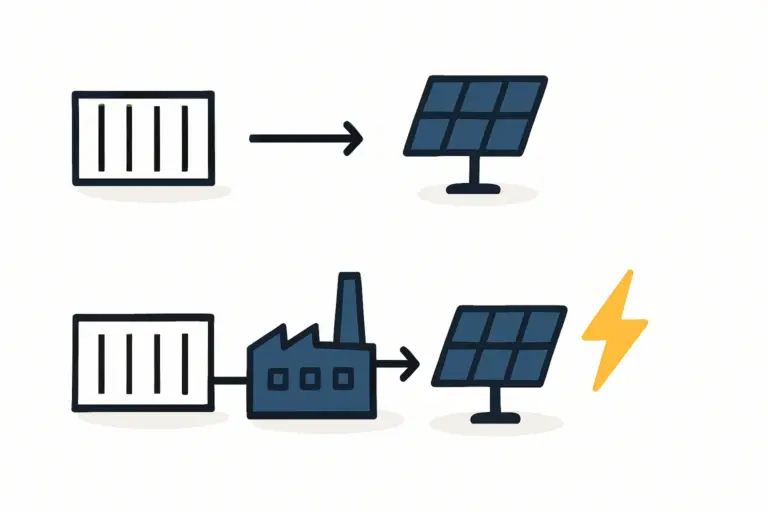

For an entrepreneur without a deep technical background in photovoltaics, starting a full-scale manufacturing plant—from raw silicon to finished panel—is a capital-intensive and complex undertaking. Solar module assembly, however, is a far more accessible and strategic entry point.

This process involves sourcing high-quality, pre-made solar cells and other components to assemble, test, and certify finished modules locally. This model offers substantial advantages:

- Reduced Capital Investment: The initial outlay is significantly lower compared to vertically integrated manufacturing.

- Faster Time-to-Market: A turnkey assembly line can be planned, installed, and commissioned in under a year.

- Direct Quality Control: On-site supervision ensures every module meets stringent standards, building a reputation for reliability.

- Market Agility: The facility can adapt production to meet local demand for specific module sizes or technologies, something international suppliers cannot do efficiently.

An annual capacity of 20 MW is the ideal starting point for this venture—large enough to achieve economies of scale and profitability, yet small enough to keep the initial investment manageable and align with current project sizes in the C&I (Commercial and Industrial) sector.

Structuring Your Solar Module Assembly Operation

Success hinges on a clear understanding of the core components. A turnkey solar panel production line provides a structured, de-risked approach where a single partner manages the technical complexities from planning to commissioning.

1. The Production Line and Machinery

The assembly process follows a logical sequence, and a semi-automated 20 MW line balances cost-efficiency with high-quality output. The turnkey setup includes all required machines for solar panel manufacturing, typically including:

- Cell Stringer: Connects individual solar cells into strings.

- Layup Station: Assembles the layers of the module (glass, EVA, cell matrix, backsheet).

- Laminator: Fuses the layers together under heat and vacuum to protect the cells from the environment.

- Framer: Adds a protective aluminum frame for structural integrity.

- Sun Simulator: Tests each finished module’s electrical performance to ensure it meets its power rating.

2. Investment and Financial Planning

While Lebanon’s banking crisis presents unique financing challenges, it also encourages innovative funding solutions. A comprehensive solar panel manufacturing business plan is crucial for securing capital. Potential funding sources include:

- International Finance Institutions (IFIs): Organizations focused on development and renewable energy projects in the region.

- Private Equity and Venture Capital: Investors seeking opportunities in growth sectors like renewable energy.

- Special Purpose Funds: Initiatives like Cedar Oxygen have been established to support Lebanon’s productive sectors.

Experience gained from European PV manufacturers’ turnkey projects shows that the investment for the machinery and setup of a 20 MW facility is a fraction of what a fully integrated factory would require, making it a highly attractive proposition for private investors.

3. Operations and Labor

A key advantage for Lebanon is its educated and capable workforce. A 20 MW assembly line typically requires a staff of 25–35 individuals, including skilled technicians, machine operators, and quality control inspectors. With proper training provided by the turnkey partner, a local team can quickly achieve high levels of operational efficiency and product quality.

From Production to Profit: A Go-to-Market Strategy

Establishing the facility is only the first step. A focused go-to-market strategy is critical for success.

Target Clientele

The primary customers for a Lebanese module assembly plant are the hundreds of local solar installers and EPC (Engineering, Procurement, and Construction) companies currently importing panels. By offering a high-quality, locally available product, your facility becomes a key partner in their supply chain, enabling them to complete projects faster and with greater confidence.

Competitive Advantage

Competing with mass-produced modules from Asia is not about price alone. The strategic advantage lies in a superior value proposition:

- Availability: Drastically reduced lead times compared to the 2-3 months for sea freight.

- Quality Assurance: A ‘Made in Lebanon’ brand built on transparent, verifiable quality.

- Local Support: Offering direct technical support and warranty fulfillment.

- Reduced Risk: Insulating clients from international shipping costs and currency exchange volatility.

Profitability and ROI

The business model is robust. By adding value locally through assembly, the final product can be priced competitively while still generating healthy profit margins. Supportive government policies—such as Law 40 (enabling net-metering) and Law 129 (regulating distributed electricity production)—create a stable regulatory framework that encourages further adoption of solar energy and ensures long-term market demand. A well-managed 20 MW facility can achieve a return on investment within a few years, establishing a sustainable and profitable enterprise.

Frequently Asked Questions for Aspiring Solar Entrepreneurs in Lebanon

- Do I need a technical background in photovoltaics to start this business?

No. A key benefit of a turnkey partnership is that the technical expertise—from factory layout and machine selection to staff training and process optimization—is provided by your partner. This allows the entrepreneur to focus on business strategy, finance, and market development.

- What is the typical factory space required for a 20 MW line?

A 20 MW semi-automated assembly line generally requires a facility of approximately 1,500 to 2,500 square meters. This includes space for the production line itself, raw material storage, and warehousing for finished modules.

- How can a local plant compete with lower-priced Chinese modules?

Competition is based on value, not just price. A local facility competes by offering immediate availability, eliminating international shipping costs and delays, providing trusted local warranty and support, and ensuring a consistently high-quality product that importers cannot always guarantee.

- Where will we source the raw materials like solar cells and glass?

Raw materials are sourced from established global Tier 1 suppliers. A turnkey partner assists in establishing these initial supply chain relationships, ensuring that all components meet international quality and performance standards.

- Is the Lebanese government supportive of local manufacturing in this sector?

The government’s legal framework, particularly laws promoting renewable and distributed energy, indicates strong support for the sector’s growth. Local manufacturing aligns with national goals for energy independence and economic development, creating a favorable environment for such ventures.

Lebanon’s energy crisis, while a profound challenge, has unlocked a powerful opportunity for industrial renewal driven by necessity. For the forward-thinking entrepreneur, establishing a 20 MW solar module assembly plant is more than a sound business investment. It is a strategic move to build a resilient enterprise that directly serves a critical national need, fostering energy independence and paving the way for a more sustainable economic future.

Download the Lebanon 20 MW Solar Plant Case Study (PDF)

Author: This case study was prepared by the

turnkey solar module production specialists at J.V.G. Technology GmbH

It is based on real data and consulting experience from J.v.G. projects

worldwide, including installations ranging from 20 MW to 500 MW capacity.