An entrepreneur in Lebanon sees the immense potential of solar energy. With clear demand and strong ambition, a fundamental question often becomes the first major hurdle: how to establish a reliable flow of raw materials?

Where do the solar cells, the glass, and the specialized films come from? How can they be navigated through international waters and local customs to a factory floor in the Beqaa Valley or near Tripoli? This isn’t merely a purchasing task; it’s the creation of a global supply chain—the lifeblood of any successful manufacturing operation.

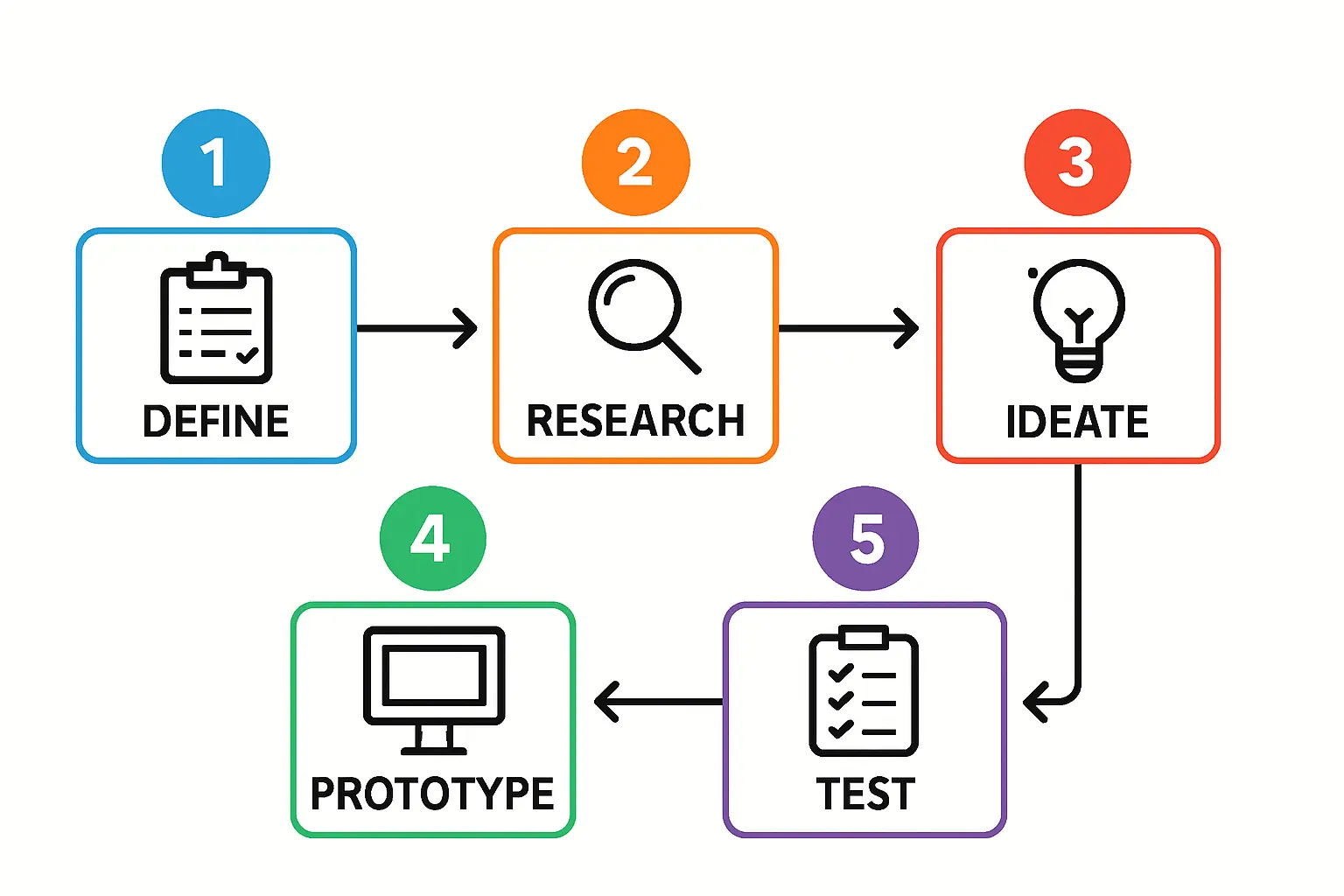

This guide offers a strategic overview for business professionals in Lebanon considering entry into solar module manufacturing. It outlines the core components, compares key sourcing regions, and breaks down the logistical realities of importing into Lebanon, transforming a complex challenge into a manageable business process.

Understanding the Core Components of a Solar Module

Before developing a sourcing strategy, it’s essential to understand the primary materials that make up a finished solar panel. Each component has its own distinct supply chain, with unique costs, lead times, and quality considerations.

The main raw materials include:

- Solar Cells: The most critical and technologically sensitive component. These wafers convert sunlight into electricity.

- Solar Glass: Specially tempered, low-iron glass that protects the cells while maximizing light transmission.

- EVA (Ethylene Vinyl Acetate) Foil: An encapsulant film used to laminate the components together, protecting the cells from moisture and impact.

- Backsheet: The final layer on the rear of the panel, providing mechanical protection and electrical insulation.

- Aluminum Frame: Provides structural rigidity and a means for mounting the module.

- Junction Box: A small, weatherproof enclosure on the back of the panel where the electrical connections are made.

Understanding the function and origin of each part is the first step toward building a resilient procurement plan. For a more detailed breakdown, a foundational review of the [Anatomy of a Solar Panel: Key Components Explained] can be highly beneficial.

The Global Supply Chain: Comparing Asian and Regional Suppliers

The majority of solar raw materials, particularly high-efficiency solar cells, originate from manufacturers in East and Southeast Asia. However, regional suppliers, especially in Turkey and Egypt, are emerging as viable alternatives for certain components. A successful strategy often involves a balanced approach that leverages the strengths of each region.

Sourcing Region: Asia (China, Vietnam, etc.)

- Primary Advantages: Lower unit cost for key components (cells, EVA), vast selection of suppliers, and access to latest cell technology.

- Primary Challenges: Long shipping lead times (30–45 days), complex logistics and potential for delays, and requires robust quality control measures.

- Best For: High-tech, high-volume components like solar cells and specialized films.

Sourcing Region: Regional (Turkey, Egypt, etc.)

- Primary Advantages: Shorter shipping lead times (5–10 days), simplified logistics, and easier for factory visits and quality audits.

- Primary Challenges: Higher unit cost for some items, limited selection for high-efficiency cells, and potential for currency volatility.

- Best For: Bulky or heavy materials like aluminum frames and solar glass; standard components.

Navigating Lebanon’s Import Logistics

A cost-effective sourcing deal can quickly become unprofitable if local logistics aren’t managed with precision. In Lebanon, this means careful planning around ports of entry, customs procedures, and financial transactions.

Ports of Entry: Beirut and Tripoli

Lebanon’s primary maritime gateways are the Port of Beirut and the Port of Tripoli.

- Port of Beirut: As the country’s main port, it has extensive experience handling containerized freight and established clearance processes. However, it can also face congestion.

- Port of Tripoli: A growing alternative that may offer less congestion and potentially faster processing times, making it a strategic option for your supply chain.

The choice of port impacts delivery schedules and inland transportation costs, so it should be made in consultation with a reputable local logistics partner.

Customs Clearance and Tariffs

This is often the most underestimated phase of the import process. Each component must be correctly classified with a Harmonized System (HS) code to determine the applicable tariffs and duties. Any error in this documentation can lead to significant delays and financial penalties.

Engaging an experienced customs broker who specializes in industrial imports is not merely advisable—it is essential. Based on J.v.G.’s experience with turnkey projects in the MENA region, customs can cause an unforeseen delay of two to four weeks if documentation fails to align perfectly with local requirements.

Currency and Payment Terms

Given Lebanon’s economic situation, structuring payments to international suppliers requires careful planning. Using secure financial instruments like a Letter of Credit (L/C) issued by a reputable bank provides assurance to both the buyer and the seller. All contracts should clearly define the currency of transaction to mitigate risks associated with exchange rate fluctuations.

Strategic Sourcing: Building a Resilient Supply Chain

Relying on a single supplier or region is a significant risk; a more robust strategy involves diversification.

A practical hybrid model could involve:

- Sourcing high-value, technology-driven components like solar cells from leading manufacturers in Asia to secure competitive pricing and performance.

- Sourcing bulky, transport-sensitive materials like aluminum frames and glass from qualified regional suppliers in Turkey or Egypt to reduce freight costs and shorten lead times.

This approach creates a balance between cost-efficiency and logistical reliability. The selection of materials also directly influences the [solar panel manufacturing equipment] needed for your production line, making integrated planning crucial. As a practical metric, a standard 40-foot container can hold enough solar cells for approximately 1.5–2 MW of module production, with ocean transit from East Asia to Beirut typically taking 30 to 45 days.

Frequently Asked Questions (FAQ) for Lebanese Entrepreneurs

Which materials are most critical to secure first?

Solar cells are the most critical component. They dictate the final module’s power output and efficiency and typically have the longest lead times. Securing a reliable supply of quality cells should be the top priority of any sourcing plan.

How much does shipping add to the cost of materials?

While this varies significantly with global freight rates, a good rule of thumb is to budget for logistics (shipping, insurance, and clearance) to add between 5% and 15% to the final landed cost of the goods.

Is it possible to source high-quality solar glass locally or regionally?

While the most specialized tempered solar glass is often imported, exploring partnerships with industrial glass manufacturers in Turkey or Egypt is a viable strategy. For a heavy component like glass, regional sourcing can offer substantial savings on transportation.

What is the biggest logistical mistake new factory owners make?

Underestimating the time and complexity of customs clearance. Incomplete or inaccurate paperwork is the most common and costly source of delays, holding up critical materials for weeks and disrupting the entire production schedule.

Conclusion and Next Steps

Establishing a solar module factory in Lebanon is a venture with significant promise, but its success is fundamentally tied to a well-structured and resilient supply chain. Sourcing raw materials is a strategic function that requires a balance between global cost advantages and regional logistical realities.

By adopting a hybrid sourcing model, partnering with local logistics experts, and meticulously planning customs and payment processes, entrepreneurs can build a strong foundation for a competitive manufacturing operation.

A well-defined sourcing strategy is a cornerstone of a successful business plan. To further develop this aspect of your project, exploring a [sample business plan for a solar factory] can provide a structured framework for your financial and operational planning. With the right knowledge and preparation, the complexities of global logistics become a surmountable part of the journey.