When investors consider a new region for a manufacturing facility, one of their first questions is about the workforce. For a technically precise industry like solar module assembly, that question becomes critical: Does the local labor pool have the necessary skills, or will extensive and costly training be required?

For those evaluating the Kingdom of Lesotho, the answer is surprisingly promising. While direct experience in photovoltaic (PV) manufacturing is scarce, the country’s dominant industry has, perhaps unexpectedly, prepared a generation of workers for the discipline and precision required on a modern production line. This untapped potential is the key to unlocking Lesotho’s manufacturing capabilities.

The Foundation: Lesotho’s Existing Industrial Workforce

A surface-level analysis might focus on Lesotho’s high unemployment rate (approximately 22.7%) and conclude that the country offers little more than a large, untrained labor pool. A deeper look, however, reveals a structured and capable workforce, shaped significantly by the nation’s well-established textile and garment industry.

This background provides several distinct advantages for an incoming solar enterprise:

-

High Literacy and English Proficiency: With a national literacy rate of 80.1% and English as an official language, communicating and understanding technical documents is far simpler.

-

Experience with Production Line Dynamics: The textile sector has instilled a fundamental understanding of assembly line work, including shift patterns, production targets, and process-oriented tasks. Workers are accustomed to the discipline required in a manufacturing environment.

-

Familiarity with Quality Control: Garment production involves rigorous quality checks, attention to detail, and performing repetitive tasks with consistent accuracy—skills that are directly transferable to inspecting solar cells and finished modules.

The workforce is also one of the youngest in the region, suggesting a high capacity for learning and adapting to new technologies. The challenge is not a lack of industrial aptitude, but a mismatch between existing skills and the specific technical requirements of PV manufacturing.

From Textiles to Technology: Bridging the Skill Gap

A solar module factory is a sophisticated manufacturing environment. While the work ethic forged in other industries is valuable, a structured training program is essential to bridge the gap between general industrial skills and specialized PV knowledge. A typical solar panel production line requires proficiency in several key areas that will be new to most entrants.

The program’s primary objective is to build targeted technical expertise upon this existing foundation of discipline and familiarity with manufacturing processes.

Core Technical Competencies for Solar Assembly

Transitioning the workforce involves developing skills in three main categories:

1. Machine Operation

Modern solar manufacturing is semi-automated. Operators do not need an engineering background, but they must be trained to manage and troubleshoot specific machinery with precision. This includes:

-

Stringer Machines: Handling and loading delicate solar cells for automatic soldering.

-

Layup Stations: Assembling the ‘sandwich’ of glass, encapsulant, cells, and backsheet with perfect alignment.

-

Laminators: Operating the high-temperature vacuum machines that cure the modules.

-

Framing and Junction Box Stations: Performing the final assembly steps according to strict specifications.

2. Quality Control and Inspection

Quality is paramount in solar module production. Staff must be trained to use specialized testing equipment and develop a keen eye for defects.

-

Visual Inspection: Identifying micro-cracks, soldering defects, or alignment issues in solar cell strings.

-

Electroluminescence (EL) Testing: Operating EL testers to see invisible defects within the cells before and after lamination.

-

Sun Simulation (Flasher): Correctly operating the flash tester to classify modules by their power output.

3. Materials Handling and Safety

Workers must learn to handle expensive and fragile components like solar cells and glass with extreme care. This includes understanding electrostatic discharge (ESD) protocols and adhering to workplace safety standards specific to the chemicals and equipment used.

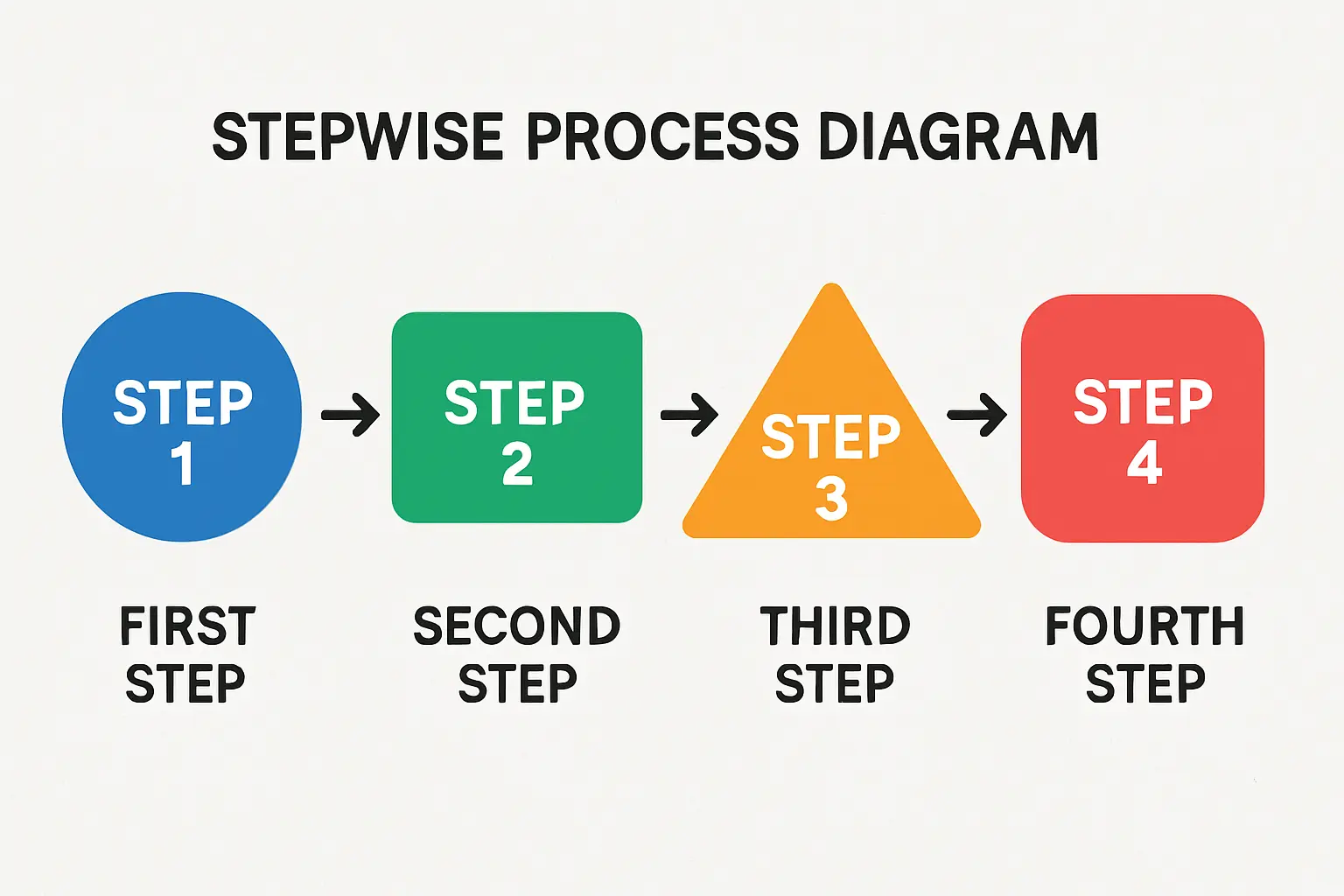

Designing an Effective Training Program: A Phased Approach

Based on experience from J.v.G. Technology GmbH turnkey projects, a comprehensive training program can transform a motivated but inexperienced team into a proficient workforce in approximately 4 to 8 weeks. The process is typically managed by experienced engineers from the technology provider and divided into distinct phases.

Phase 1: Theoretical Foundation (1–2 weeks)

This classroom-based phase covers the fundamentals of photovoltaic technology. Workers learn why each step is important, not just how to do it. Topics include:

-

How a solar cell works.

-

The function of each component in a solar module.

-

The critical impact of quality control on module lifetime and performance.

-

Workplace safety and ESD prevention.

Phase 2: Hands-On Equipment Training (2–4 weeks)

Under the direct supervision of expatriate trainers, local staff begin working on the actual production machinery. This phase focuses on:

-

Machine setup, operation, and basic maintenance.

-

Practicing each production step until quality and speed meet industry standards.

-

Learning to identify and flag production anomalies.

Phase 3: Process Integration and Team Development (2 weeks)

In this final phase, the focus shifts from individual tasks to operating as a cohesive production line. The goal is to build teamwork, streamline workflow, and empower local team leaders. This is a crucial step in any plan for how to start a solar panel manufacturing business.

The objective of this ‘train the trainer’ model is to establish self-sufficiency. International experts transfer knowledge and establish best practices, ultimately empowering a local management and training team to handle ongoing operations and new employee onboarding.

Frequently Asked Questions (FAQ)

How long does it typically take to train a new production team in Lesotho?

For a core team of 20-30 operators and technicians with no prior solar experience, a comprehensive training program led by experienced engineers usually takes 4 to 8 weeks to achieve initial operational proficiency. Continuous improvement and deeper skill development occur over the following months.

Can local technical institutions in Lesotho support this training?

Yes. Institutions like Lerotholi Polytechnic and the National Technology Training Centre (NTTC) are actively working to address skills gaps with Technical and Vocational Education and Training (TVET) programs. Partnering with these institutions can be an excellent strategy for sourcing candidates with a foundational technical aptitude, potentially shortening the in-house training cycle.

What are the typical labor costs for a solar factory worker in Lesotho?

While wages vary, the country’s minimum wage for factory workers provides a baseline, currently around LSL 2,427 (approximately USD 130) per month. Skilled operators and technicians in a specialized industry like solar manufacturing would command a higher wage, but labor costs remain highly competitive globally. This is an important factor in the overall solar panel manufacturing plant cost.

Is finding workers with a strong work ethic a challenge?

The established textile industry has cultivated a workforce that is familiar with the demands of factory production. Candidates generally understand the importance of punctuality, following procedures, and teamwork. The key is to implement a strong management structure that reinforces these principles within the context of high-tech manufacturing.

Conclusion: A Workforce with Untapped Potential

The labor force in Lesotho represents a significant opportunity for investors in the solar manufacturing sector. The country offers more than just a pool of available labor; it provides a workforce with a foundational understanding of industrial processes, a high literacy rate, and a proven capacity for detailed, repetitive work.

The path to establishing a proficient solar module assembly team does not require finding pre-existing experts. Instead, it requires a well-structured, targeted training program that builds upon the country’s solid industrial foundation. With the right investment in knowledge transfer and skill development, Lesotho’s workforce can become a key asset in building a competitive and successful solar manufacturing operation.