An investor has procured a complete production line for a new manufacturing facility. The advanced machinery, worth millions, has been shipped and is awaiting collection at the port.

For a project in a landlocked country like the Kingdom of Lesotho, this is where the most complex phase of the journey begins. The final 600-kilometer overland route from the Port of Durban in South Africa to the factory in Maseru presents a unique set of logistical challenges that can define the project’s timeline and budget.

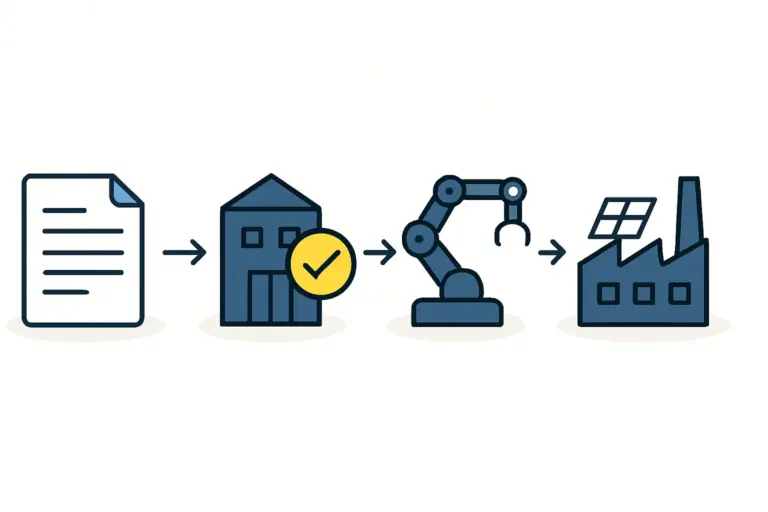

This guide outlines the critical planning required to transport heavy, sensitive manufacturing equipment into Lesotho. It covers the primary transport route, customs procedures, and typical timelines and costs, offering a foundational understanding for any entrepreneur planning an industrial venture in the region.

The Strategic Gateway: Why the Port of Durban is Key

Lesotho’s status as a landlocked developing country (LLDC) makes it entirely dependent on its neighbor, South Africa, for sea freight. As the largest and busiest shipping terminal in sub-Saharan Africa, the Port of Durban serves as the primary and most efficient gateway for cargo destined for Lesotho.

Its extensive facilities are equipped to handle various types of freight, from standard containers to the oversized, break-bulk cargo typical of industrial machinery. All equipment for a new factory, whether sensitive electronic components or heavy presses, will almost certainly first arrive on South African soil at this port.

Upon arrival, the equipment must be offloaded, processed by port authorities, and prepared for the critical overland transit. This transition from sea to land can cause significant delays if not managed by an experienced freight forwarding partner.

The Overland Journey: From Durban to the Maseru Border

Transporting heavy equipment overland from Durban to Lesotho is a specialized logistical operation. The standard route follows the N3 highway—a well-maintained corridor—for approximately 600 kilometers to the Maseru Bridge Border Post.

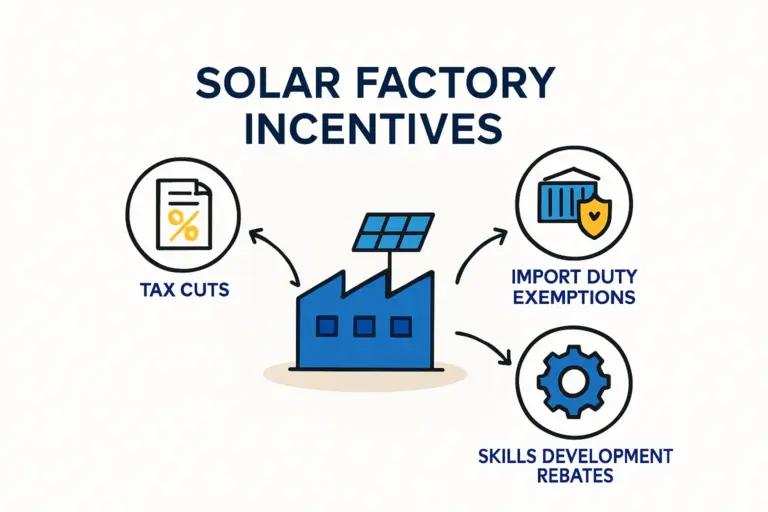

While the highway itself is in good condition, moving a full turnkey solar module manufacturing line, for example, requires meticulous planning. Key considerations include:

-

Vehicle Selection: The weight and dimensions of the crated machinery dictate the type of trucks needed, which can range from standard flatbeds to specialized low-bed trailers for oversized or heavy loads.

-

Secure Lashing and Crating: Sensitive manufacturing equipment is susceptible to damage from vibration and shock. Professional industrial crating and secure lashing are non-negotiable to ensure the machinery arrives in perfect condition. Based on experience from J.v.G. turnkey projects, inadequate crating is a leading cause of equipment damage during transit.

-

Permits for Abnormal Loads: If any piece of equipment exceeds standard weight or size limits, special permits must be obtained from South African road authorities—a process that requires advance planning.

This detailed planning must extend to the final few kilometers to the factory site within Lesotho. Local roads must be surveyed to ensure they can accommodate the delivery vehicles. This survey is a crucial part of the overall factory building requirements.

Navigating the Final Hurdle: Customs and Border Crossing

The border crossing is often the most unpredictable stage of the journey. Lesotho is a member of the Southern African Customs Union (SACU), along with Botswana, Eswatini, Namibia, and South Africa.

While SACU provides for a common external tariff and duty-free movement of goods between members, it does not eliminate the need for formal customs procedures. All goods must be formally cleared for export from South Africa and import into Lesotho. The Maseru Bridge Border Post, the main point of entry, can be a significant bottleneck.

Successful customs clearance depends entirely on meticulous documentation. A competent customs broker is essential to prepare and submit the required paperwork, which typically includes:

-

Bill of Lading: The contract between the equipment owner and the shipping line.

-

Commercial Invoice: Details the value of the goods.

-

Packing List: An itemized list of the shipment’s contents.

-

Certificate of Origin: Certifies the country where the goods were manufactured.

-

Customs Declarations (SAD 500 in South Africa): Formal entry documents for both countries.

Even minor errors in this paperwork can lead to significant delays, inspections, and potential penalties, holding up the entire project.

A Practical Timeline and Cost Framework

Budgeting for both time and cost is critical. While every shipment is different, the following framework can be used for planning purposes:

Typical Timeline (from Durban port to Maseru factory):

- Port Unloading & Handling: 2–5 working days.

- Customs Pre-Clearance: 1–2 working days (can be done while goods are at port).

- Road Transport to Border: 1–2 days.

- Border Crossing & Final Clearance: 1–3 working days, highly variable.

- Final Delivery & Unloading: 1 day.

Total Estimated Time: 5–11 working days. Prudent project managers should budget for at least 15 working days to account for potential delays.

Key Cost Components:

- Port Charges: Terminal handling fees and other statutory port costs.

- Road Freight: Calculated based on the number of trucks, distance, and weight. Specialized transport for abnormal loads is significantly more expensive.

- Customs Brokerage Fees: Fees for the agent managing the clearance process.

- Insurance: Comprehensive marine and inland cargo insurance is essential.

- Potential Demurrage/Storage: Fees incurred if cargo is not cleared from the port or border within a specified free period.

Frequently Asked Questions (FAQ)

What is SACU and how does it affect imports into Lesotho?

The Southern African Customs Union (SACU) is a customs union among five countries in Southern Africa. For an investor, this means that once goods are cleared into any member country (in this case, South Africa), they can, in theory, move to another member country (Lesotho) without incurring additional import duties. However, formal customs declarations and VAT procedures are still required at the border.

Are there import duties on manufacturing equipment?

Under SACU’s Common External Tariff, capital equipment and machinery for manufacturing are often eligible for duty-free importation, though this depends on the specific tariff code of the goods. It is vital to have your customs broker verify the exact tariff classifications and any applicable rebates or exemptions well in advance. Value Added Tax (VAT) is typically payable.

What type of insurance is necessary?

‘All-risk’ Marine Cargo Insurance that extends to cover the inland transit from Durban to the final factory site in Lesotho is essential. This policy should cover loss or damage to the equipment from the moment it leaves the supplier until it is delivered.

How long should I budget for the Durban-to-Maseru leg?

While the transport itself may take only a day or two, the entire process from ship-to-shore to factory door should be allocated at least two to three weeks in the project plan to absorb any unforeseen customs or transport delays.

Is it possible to use a different port?

While other South African ports like Port Elizabeth or Cape Town are options, they involve a much longer and more expensive overland journey to Lesotho. Durban remains the most logical and cost-effective choice for sea freight.