Imagine a critical phase in the solar module production line: lamination. Multiple layers of materials are heated and pressed under a vacuum to form a durable solar panel. Suddenly, the power cuts out. The machine halts, the process is ruined, and an entire batch of valuable materials is lost. This scenario—a direct result of an unstable power supply—is one of the most significant operational risks for any high-tech manufacturer, especially in regions with developing infrastructure.

For any entrepreneur considering a solar panel factory in Liberia, understanding the local power landscape isn’t a secondary detail—it’s foundational to success. Here, we’ll objectively analyze Liberia’s national grid and evaluate the strategic alternative of a captive power plant, an essential step for ensuring the operational continuity modern manufacturing demands.

The Critical Role of Uninterrupted Power in Solar Module Manufacturing

Solar module assembly involves several energy-intensive, time-sensitive processes. Key stages such as cell stringing, lamination, and curing all depend on a constant and clean supply of electricity.

Process Sensitivity: Automated machines like stringers and laminators require precise control. An abrupt shutdown can cause physical damage to the equipment or lead to misaligned components, creating defective products.

Material Waste: The lamination cycle is irreversible, so a power failure at this stage means a complete loss of all materials involved—solar cells, EVA film, glass, and backsheets. This waste directly impacts production costs and efficiency.

Production Downtime: Every hour of downtime translates directly to lost revenue. Frequent interruptions severely hamper a factory’s ability to meet production targets and fulfill orders, undermining its financial viability.

Given these high stakes, a reliable power source is non-negotiable. This foundational requirement is central to any robust business plan for starting a solar panel factory.

An Overview of Liberia’s National Power Grid

An investor’s decisions must be based on a realistic assessment of the local infrastructure. Liberia’s national grid, managed by the Liberia Electricity Corporation (LEC), comes with a distinct set of challenges.

Based on 2021 data, the LEC’s total installed capacity was approximately 126 MW. However, the country’s electrification rate remains low, with only about 28% of the population having access to electricity. This points to a system under strain—a reality with direct implications for industrial users.

Key considerations include:

Seasonal Dependency: A significant portion of Liberia’s power comes from the Mount Coffee Hydropower Plant. During the dry season (December to May), the plant’s output can decrease dramatically, forcing the grid to rely on expensive thermal generation from heavy fuel oil (HFO) and diesel.

High Tariffs: The reliance on imported fossil fuels for generation gives Liberia some of the highest electricity tariffs in the world. This makes grid electricity a major operational cost for an energy-intensive factory.

Reliability Issues: The combination of limited capacity, aging infrastructure, and significant transmission and distribution losses leads to frequent and often unpredictable power outages.

While connecting to the West African Power Pool (WAPP) offers a long-term prospect for more stable and affordable electricity, entrepreneurs planning for the immediate future must contend with the current realities of the domestic grid.

The Business Case for Captive Power Generation

In response to grid instability, many industrial operations in emerging markets turn to ‘captive power generation’—an on-site power plant dedicated to serving their own facility. This approach shifts control over power reliability and cost from the public utility to the business owner.

For a solar factory in Liberia, there are two primary captive power options:

-

Diesel Generators: The traditional solution for backup power, they offer high reliability but come with significant drawbacks, including high and volatile fuel costs, frequent maintenance, and environmental concerns.

-

Solar PV Captive Plant: This involves installing a dedicated solar power system, often supplemented with battery storage, to power the factory. While the initial capital expenditure is higher, it provides predictable, low-cost energy and insulates the business from fluctuating fuel prices. For a solar panel manufacturer, this also becomes a powerful demonstration of its own product.

The choice between the grid, diesel, or solar is a critical part of the financial modeling in a solar panel manufacturing business plan. In a high-tariff environment like Liberia’s, the return on investment for a solar captive plant can be surprisingly rapid.

Designing a Resilient Power Solution for a Liberian Solar Factory

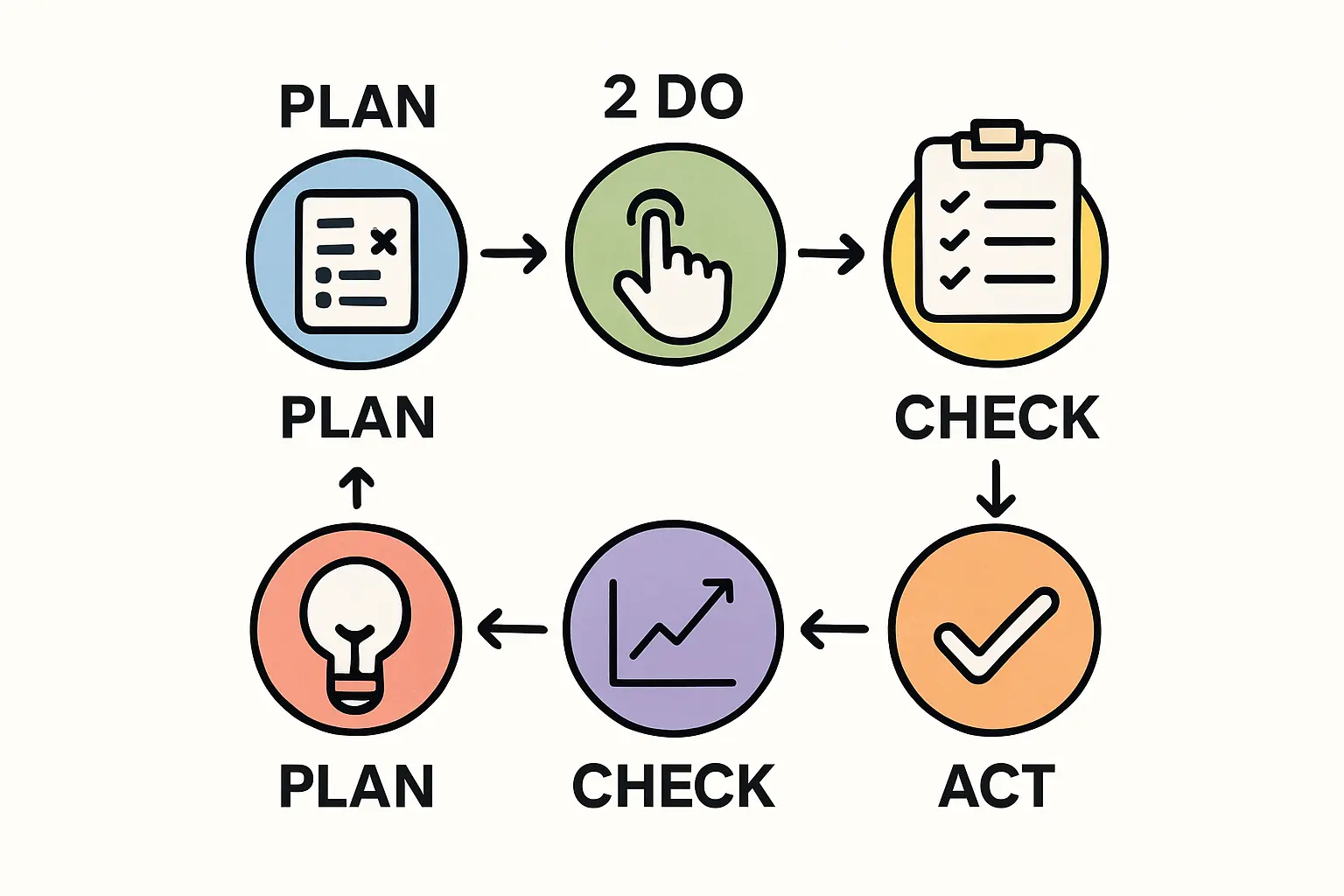

Based on experience from J.v.G. Technology GmbH turnkey projects in similar markets, the most effective strategy is a hybrid system that combines multiple technologies for maximum resilience and cost-effectiveness.

A well-designed hybrid system might include:

Primary Power Source: A large-scale solar PV array, sized to meet the factory’s peak daytime demand.

Energy Storage System (ESS): Industrial-grade batteries store excess solar energy from the day to power operations at night or to stabilize the power supply during brief grid fluctuations.

Backup Generator: A smaller diesel generator serves as a final layer of security, designed to operate only during extended periods of low solar generation (e.g., prolonged bad weather) or during system maintenance.

This integrated approach combines the low operational costs of solar, the 24/7 reliability of battery storage, and the ultimate security of a backup generator. Planning for such a system is a key part of defining the overall factory building requirements, as it requires dedicated space and infrastructure.

Frequently Asked Questions (FAQ)

What exactly is a captive power plant?

A captive power plant is a power generation facility owned and operated by a private entity for its own consumption. It operates independently of the national grid, providing a reliable power supply directly to the industrial facility it serves.

Why is stable power so important for solar panel manufacturing machines?

Sensitive automation and thermal processes in machines like stringers and laminators require uninterrupted power to operate precisely. Power loss can cause immediate material waste, damage to robotic components, and lengthy production delays as systems are reset and recalibrated.

Can a new factory in Liberia rely solely on the national grid?

While theoretically possible, relying exclusively on the Liberian national grid presents a substantial business risk due to documented issues with reliability and high costs. Most industrial operators invest in at least a backup power solution to protect their operations.

What is the typical payback period for a captive solar plant in a high-tariff region?

The payback period depends on the system’s cost, local electricity tariffs, and solar irradiation levels. In regions with very high electricity prices like Liberia, the payback period for a commercial solar power plant can be significantly shorter than the global average, often falling within a 3- to 6-year range.

How does the rainy season in Liberia affect a solar captive power plant’s output?

During the rainy season, cloud cover reduces a solar array’s output, but a properly designed system accounts for this seasonality. The system is typically oversized to produce sufficient energy even on overcast days and works with a battery storage system and a backup generator to ensure uninterrupted power year-round.

Conclusion: Securing Production with Strategic Power Planning

For any entrepreneur planning to enter the solar manufacturing sector in Liberia, the question is not if a power strategy is needed, but which strategy is most prudent. The evidence suggests that relying solely on the national grid creates an unacceptable level of operational and financial risk.

An investment in a captive power solution—particularly a hybrid system centered on solar PV—should be viewed not as an additional cost but as a foundational investment in production continuity, cost control, and long-term business resilience. Addressing the power question early in the planning process is a hallmark of any well-prepared and successful manufacturing venture.