Choosing a location for a new solar module factory is one of the most foundational decisions an entrepreneur can make. While machinery and business plans often take center stage, a facility’s physical address can determine its logistical efficiency, operational costs, and long-term viability.

An ideal site is far more than a plot of land; it is a strategic asset. This article uses the Grand Duchy of Luxembourg as a case study to illustrate the methodical process of site selection. While specific to this European jurisdiction, the core principles of evaluating infrastructure, utilities, and regulations apply universally to any entrepreneur planning to enter the solar manufacturing industry, whether in the Middle East, Africa, or the Americas.

Key Factors in Industrial Site Selection for a Solar Factory

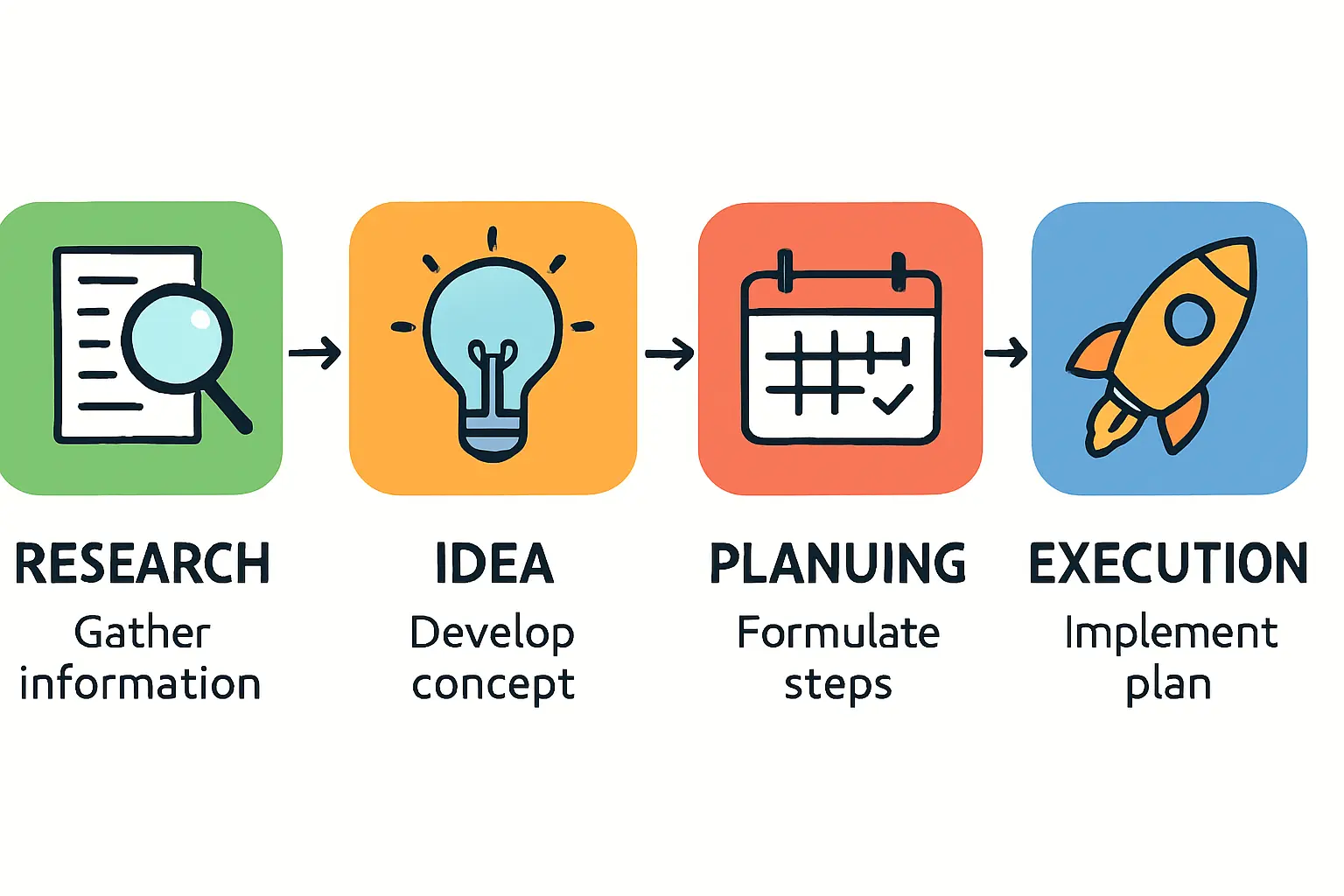

A thorough site selection process for a mid-scale (e.g., 20–50 MW) solar module factory balances four critical pillars. A weakness in any one of these areas can lead to significant unforeseen costs and delays.

-

Logistics and Transport: Efficient movement of raw materials like glass, aluminum frames, and solar cells, as well as finished modules, is paramount. Proximity to major motorways, rail terminals, or ports can drastically reduce transportation costs and lead times.

-

Utilities and Infrastructure: Solar manufacturing demands a significant and stable electrical supply, along with reliable access to water and data connectivity. The availability and cost of connecting to a high-capacity grid is a common bottleneck.

-

Land and Building Suitability: The site must accommodate the factory footprint, storage, and potential for future expansion. Zoning laws must permit industrial manufacturing activity.

-

Regulatory and Labor Environment: The process for obtaining building permits, the quality of the local labor pool, and available government incentives all influence the final decision.

Evaluating Luxembourg’s Primary Industrial Zones

Luxembourg, strategically located at the heart of Europe, has several designated industrial zones, each with distinct advantages. For a prospective solar module manufacturer, the choice between them will depend on specific business priorities.

The Southern Logistics Hub: Sanem/Differdange and Bettembourg

This region, historically the country’s industrial core, has transformed into a premier logistics hub.

Logistics: Its primary advantage is proximity to the A4 and A13 motorways, providing direct access to France, Belgium, and Germany. The Eurohub Sud logistics park, home to the Bettembourg-Dudelange intermodal terminal, seamlessly connects rail and road transport. This is ideal for an operation relying on a mix of European raw material suppliers and global exports.

Utilities: The electrical grid in this area is robust, built to support heavy industry. However, confirming the specific substation capacity for a new project is an essential step. Based on project experience, a typical 50 MW solar module manufacturing line requires a power connection of 500–800 kVA.

Land: While highly sought after, plots suitable for industrial development can still be found. A common challenge is finding a plot of 8,000–10,000 m² large enough to comfortably accommodate the production hall, warehouse, and administrative offices.

The Northern Development Axis: Lentzweiler and Wiltz

The north of Luxembourg is an area targeted for economic development and often presents different opportunities.

Logistics: While further from the southern hub, these zones offer excellent connectivity to Belgium and Germany via efficient, less-congested road transport.

Utilities: Verifying utility access is particularly critical here. Although the infrastructure is modern, it may not have the same inherent capacity as in the south. Early consultation with the national grid operator, Creos, is essential.

Land and Incentives: Land is often more readily available and may be offered with government incentives aimed at encouraging regional investment. This can have a positive impact on the overall investment required for a solar factory.

The Eastern Connectivity Corridor: Mertert and Potaschberg

This region offers a unique logistical advantage not found elsewhere in the landlocked country.

Logistics: Its key asset is the Port of Mertert on the Moselle River. This allows for cost-effective transport of bulk materials, like solar glass, via barge from major European ports such as Antwerp. For a manufacturing process where glass is a primary cost component, this can create a significant competitive edge.

Utilities and Land: These zones are well-established, with good road links via the A1 motorway and reliable utility infrastructure. A detailed assessment is still needed to ensure a specific plot can accommodate the factory’s production flow.

The Critical Role of Utilities and Zoning

Beyond geography, two technical aspects often dictate a project’s timeline and feasibility.

Power and Water: Non-Negotiable Requirements

A stable, high-capacity power supply is the lifeblood of a solar factory. Lamination machines, cell stringers, and testing equipment all consume significant energy. Securing a grid connection can take 6 to 12 months in many jurisdictions, so this process must begin at the earliest stage of planning. This timeline also directly influences the selection of necessary production machinery.

Navigating Zoning Regulations (PAG and PAP)

In Luxembourg, as in many regulated markets, land use is governed by strict plans.

PAG (Plan d’Aménagement Général): This is the general municipal zoning plan that designates areas for industrial, commercial, or residential use. The chosen site must be within a zone designated for industry.

PAP (Plan d’Aménagement Particulier): This is a detailed development plan for a specific plot or project. For a new factory, a PAP often needs to be created and approved by municipal authorities, dictating building placement, height, parking, and environmental considerations. This process requires expert guidance from local architects and planners.

A Universal Framework for Site Selection

While this analysis focuses on Luxembourg, the methodology is universal. An entrepreneur in Nigeria must assess proximity to the Port of Lagos with the same diligence as one in Luxembourg assesses the Bettembourg terminal. An investor in Saudi Arabia must verify grid capacity in an industrial city just as one would in Wiltz.

The pvknowhow.com educational platform offers structured guidance to help investors apply this proven framework to their own local context, helping them take this critical first step with confidence.

Frequently Asked Questions (FAQ)

What is the typical land size needed for a 50 MW solar module factory?

For a 50 MW annual capacity line, a land plot of 8,000 m² to 10,000 m² is recommended. This allows for a factory building of roughly 3,000–4,000 m², with adequate space for raw material storage, finished goods warehousing, truck access, and future expansion.

How long does it take to get building and environmental permits?

In a highly regulated market like Luxembourg, the permitting process can take anywhere from 6 to 18 months. This includes zoning plan approvals (PAP), building permits, and environmental impact assessments. Starting this process early is crucial.

Are there government incentives for setting up a manufacturing facility?

Most governments, including Luxembourg’s via agencies like Luxinnovation, offer incentives for industrial projects. These can include investment tax credits, R&D grants, or preferential loan conditions. These should be explored but should not be the sole basis for a project’s financial viability.

Why is proximity to a logistics hub so important for solar manufacturing?

Solar manufacturing is an assembly business with relatively thin margins. Inbound logistics for components (cells, glass, frames) and outbound logistics for finished panels represent a significant portion of the final product cost. Efficient logistics directly impacts profitability.

Can a non-technical entrepreneur manage this site selection process?

Yes. The key is to follow a structured process and engage the right experts. An entrepreneur does not need to be a civil engineer but must know the right questions to ask about power, logistics, and zoning. This is where guidance from experienced consultants, often as part of comprehensive turnkey factory solutions, becomes invaluable.

Conclusion: Your Next Steps in Site Selection

Selecting a site for a solar manufacturing plant is a strategic decision that sets the foundation for future success. It requires a detailed analysis of logistics, utilities, land suitability, and the regulatory landscape.

By approaching this task with a methodical framework, an investor can mitigate risks and create a powerful competitive advantage. The insights gained from a thorough site analysis are critical for developing a robust business plan and securing financing for your project.