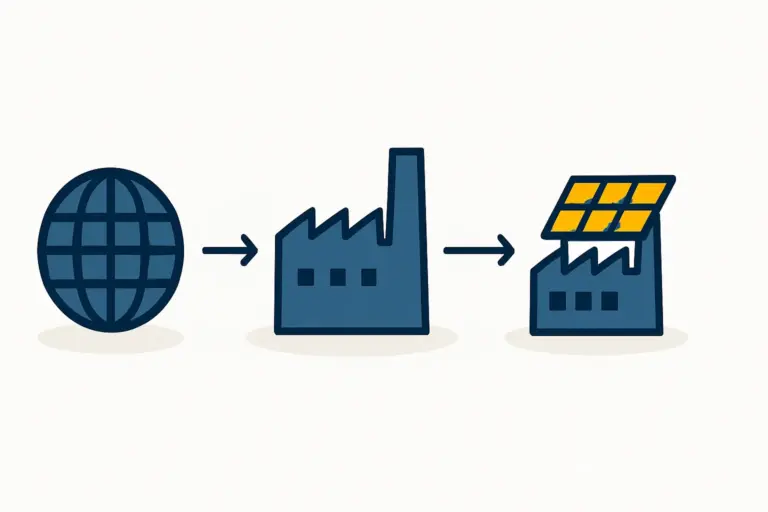

Many entrepreneurs envision solar manufacturing as a game of immense scale, with vast, automated facilities producing millions of standard panels. While this model has its place, a more strategic approach is needed in high-cost, high-innovation environments.

For an investor considering a venture in the heart of Europe, like Luxembourg, the most viable path isn’t to compete on volume, but to excel in value.

This analysis lays out the business case for establishing a specialized, high-efficiency solar module production line in Luxembourg. It shows why shifting from commodity products to advanced solutions like Building-Integrated Photovoltaics (BIPV) presents a significant and sustainable market opportunity.

Why Standard Solar Module Production is Challenging in Europe

Competing with established, large-scale Asian manufacturers on standard photovoltaic (PV) modules is a daunting challenge for any new European entrant. The primary obstacles are economic:

-

High Operational Costs: Labor, energy, and land costs in Western Europe, including Luxembourg, are substantially higher than in major manufacturing hubs in Asia.

-

Intense Price Competition: The market for standard solar panels is a commoditized space driven by price, where profit margins are continually squeezed by gigawatt-scale factories that benefit from economies of scale.

-

The Commodity Trap: A business model based on producing a standard product forces a company to compete almost exclusively on price. For a new, smaller-scale European factory, this is an unsustainable position.

Understanding these realities is the first step toward developing a more resilient and profitable business strategy. The opportunity lies not in replication, but in differentiation.

The Strategic Shift: From Volume to Value

Instead of entering a crowded commodity market, a Luxembourg-based factory can be strategically positioned to serve the growing demand for premium, customized, and technologically advanced solar products. The most prominent example is Building-Integrated Photovoltaics, a market where innovation, aesthetics, and performance command a higher price.

BIPV solutions are not simply panels mounted on a roof; they are functional parts of the building envelope itself. They include solar-active facades, roof tiles, skylights, and balustrades that generate electricity while serving their primary architectural purpose.

This market is not just a niche; it is being driven by powerful regulatory tailwinds. The European Union’s Energy Performance of Buildings Directive (EPBD) and its ‘Solar Rooftop Initiative’ mandate the installation of solar on new public, commercial, and eventually residential buildings. These regulations are transforming BIPV from an architectural choice into a building requirement, creating a predictable, long-term demand cycle that a local manufacturer is well-positioned to serve.

Luxembourg’s Unique Advantages for High-Tech Manufacturing

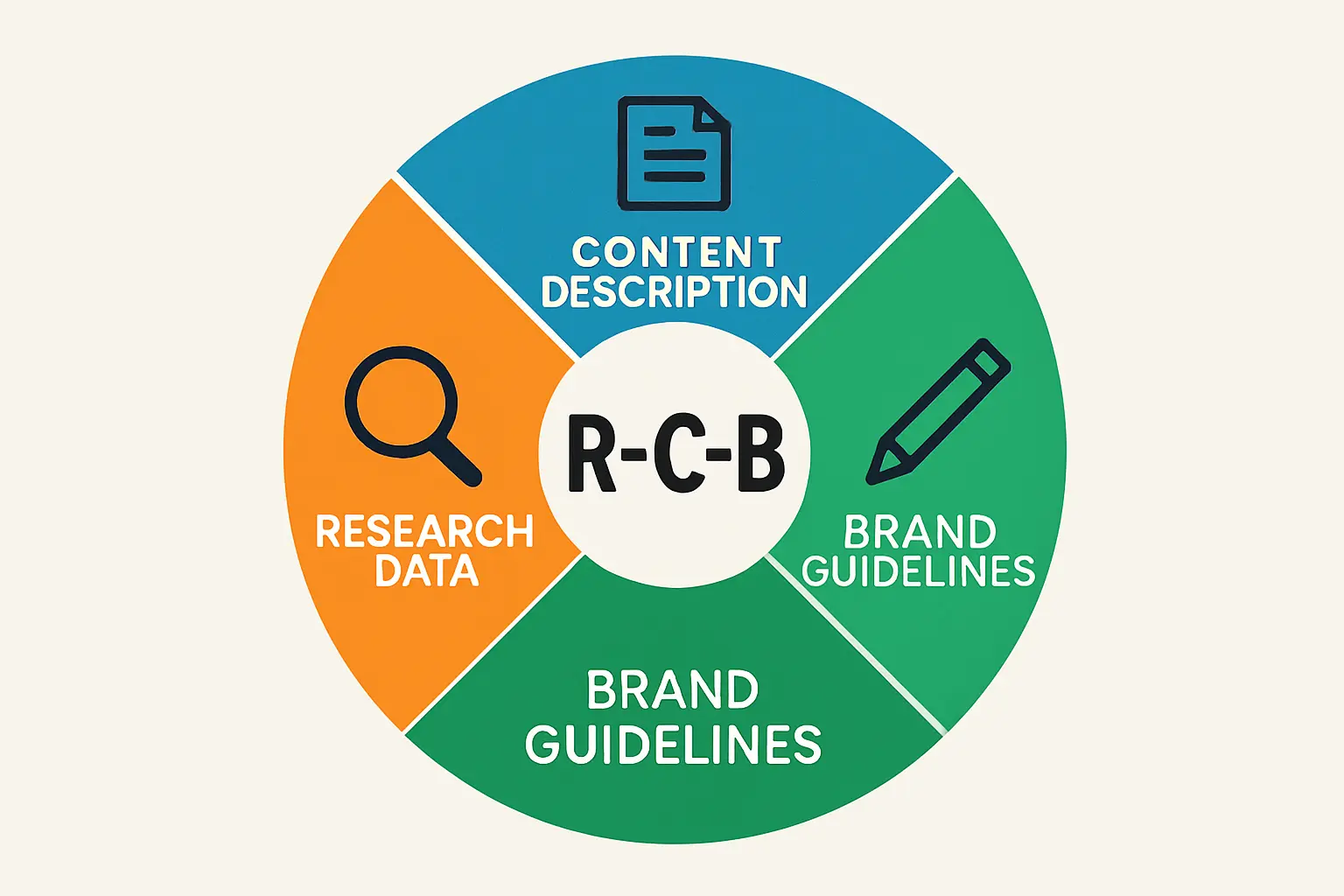

While challenging for standard production, Luxembourg’s unique characteristics make it an ideal location for a high-value manufacturing operation. The business case rests on leveraging the country’s inherent strengths, not fighting its economic realities.

R&D and Innovation Hub

Luxembourg hosts world-class research institutions, most notably the Luxembourg Institute of Science and Technology (LIST). A specialized solar factory could partner with such institutions to co-develop next-generation BIPV products, test new materials, and refine production techniques. This proximity to cutting-edge research creates a crucial competitive advantage, allowing the factory to stay at the forefront of technological innovation rather than simply following market trends.

Strategic Location and Logistics

Situated within the ‘Blue Banana’—Europe’s highly urbanized and economically powerful corridor—Luxembourg offers unparalleled logistical access to key markets in Germany, France, Belgium, and the Netherlands. For high-value, often custom-made BIPV projects, short, reliable supply chains are critical. Architects and construction firms value the ability to collaborate closely with a regional manufacturer, which reduces transport times, logistical risks, and the carbon footprint associated with intercontinental shipping.

Political Stability and Skilled Workforce

A stable political and economic environment is essential for long-term capital investment. A high-tech manufacturing operation also requires a skilled, multilingual workforce capable of managing sophisticated automated systems and engaging with an international client base. Luxembourg’s highly educated labor market is well-suited to meet these demands.

The Financial Case: Higher Margins in Niche Markets

The business model for a specialized factory pivots from thin margins on high volume to substantial margins on lower, more targeted volume. Custom architectural solar products are valued based on their performance, aesthetic integration, and bespoke nature—not just their price per watt.

This approach enables a fundamentally different financial structure. While the initial capital expenditure for a flexible BIPV production line may be comparable to a standard line of similar capacity, the potential return on each module sold is significantly higher. The business competes on quality and innovation, which are more defensible market positions than price alone.

Designing a Production Line for Flexibility and Automation

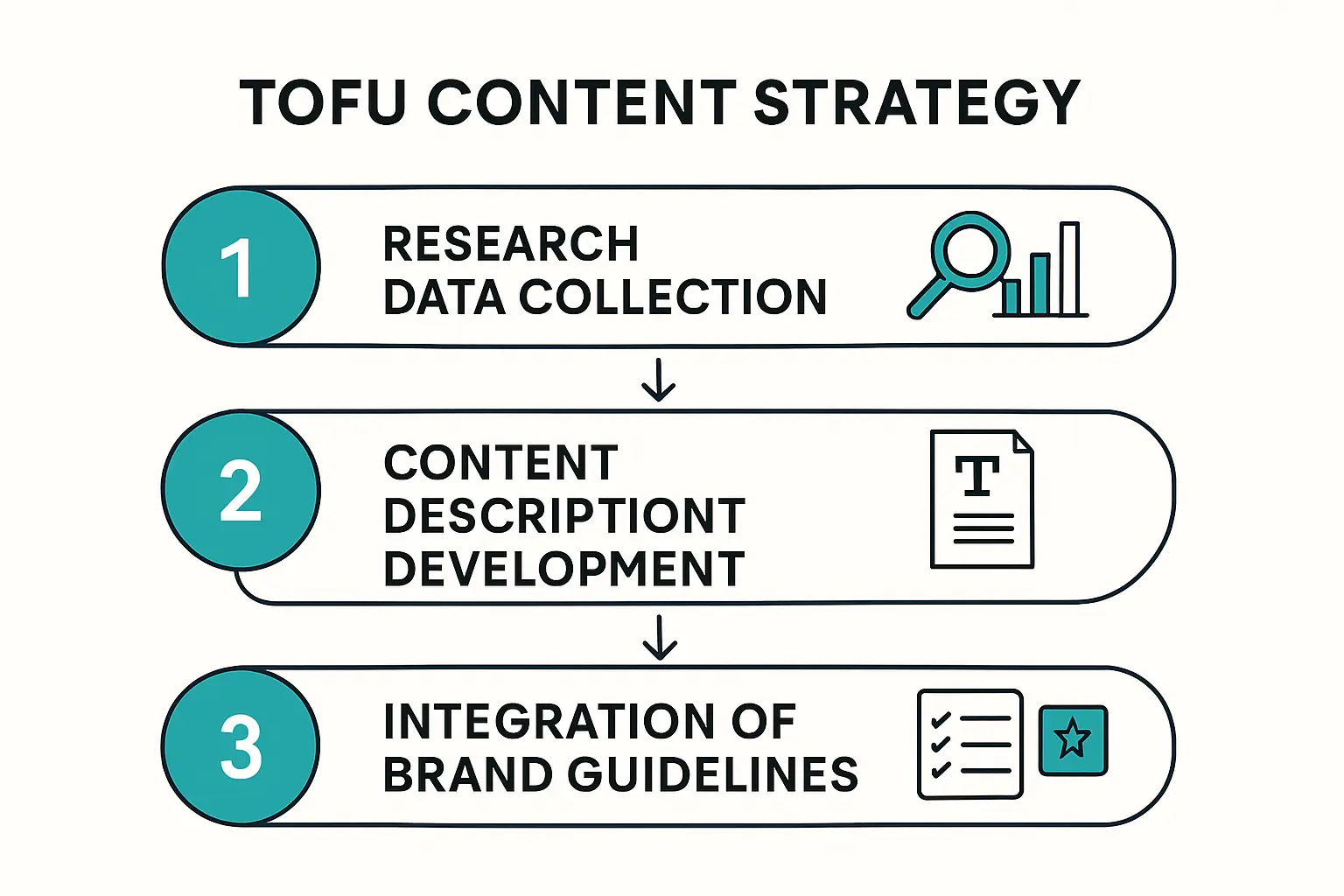

Successfully manufacturing BIPV and other custom modules requires a different approach to factory design, one guided by the principles of flexibility and automation.

Unlike a standard production line optimized to produce one size of module as quickly as possible, a BIPV line must be engineered to handle diverse formats. This means handling various sizes, shapes, colors, and types of glass or encapsulants. The factory’s core strength lies in its ability to switch between different product specifications with minimal downtime. The entire solar module manufacturing process must be adapted for this purpose.

To counteract high labor costs, the production line must be highly automated. Modern robotics and process control systems can manage complex tasks with precision, ensuring high quality while minimizing the need for on-site operators. A well-designed, automated line with a capacity of 50-100 MW is an ideal scale for this business model. It offers sufficient output to serve the European architectural market without requiring the immense capital of a gigawatt-scale facility. This scale is a key consideration for anyone learning how to start a solar module factory.

A Practical Example from the Field

Based on experience from J.v.G. turnkey projects, many initial business plans focus on standard modules. In one instance, after a detailed analysis of local labor costs and regional market opportunities in Europe, the strategy was revised to focus entirely on architectural solar. This pivot enabled the client to target a more profitable, less crowded market segment, securing development contracts with premium construction firms before the factory was even completed.

Frequently Asked Questions (FAQ)

What is the typical investment for a specialized BIPV line?

While project-specific, an investment for a 50-100 MW flexible, automated line typically ranges from €15 million to €25 million. The cost per watt is higher than for a standard line due to the more advanced and flexible machinery required, but the overall project scale is more manageable.

How does BIPV differ from standard solar panels?

Standard panels are installed onto an existing structure, whereas Building-Integrated Photovoltaics (BIPV) are integrated into the building’s design to become a functional part of it, such as the facade, roof, or windows. BIPV products must meet both energy generation and building material standards.

Is a technical background required to start such a factory?

A technical background is not a prerequisite. Many successful entrepreneurs in this field come from business, finance, or other industries. The key is to partner with experienced technical consultants and engineers who can manage the planning, equipment procurement, and operational setup. The pvknowhow.com platform is designed to provide this structured guidance.

How long does it take to set up a 50 MW flexible production line?

With a clear plan and experienced partners, a timeline of 9 to 12 months from final project approval to the start of production is realistic. This includes factory layout planning, machine procurement, installation, and commissioning.

Conclusion: A Path Forward

The business case for solar module manufacturing in Luxembourg is strong, but only if the strategy aligns with the region’s economic realities and market opportunities. The path to success is not through mass-market competition but through specialization, innovation, and a focus on high-value products like BIPV.

Leveraging Luxembourg’s R&D ecosystem, strategic location, and skilled workforce, an entrepreneur can build a profitable and sustainable enterprise that serves the future of European construction.

For investors considering this path, the next steps involve detailed financial modeling and a thorough feasibility study. Structured resources and expert-led guidance can provide a robust framework for navigating this complex but rewarding journey.