For many entrepreneurs considering solar manufacturing in Africa, the focus is often on production technology and market demand. In Madagascar, a nation with immense solar potential yet developing infrastructure, this perspective is incomplete.

A successful venture here is determined less by the sophistication of its machines than by the resilience of its supply chain. The logistical challenges of an island economy, particularly one as vast as Madagascar, are a critical and frequently underestimated factor for success.

This article examines the two most important logistical considerations for establishing a solar factory in Madagascar: selecting the optimal import port and creating a reliable inland transport network. Understanding these factors is essential for building a viable and profitable manufacturing operation.

The Strategic Importance of Port Selection in an Island Economy

In a landlocked country, one might have several overland import options. On an island like Madagascar, however, nearly every critical component for manufacturing must arrive by sea. This elevates the choice of port from a simple logistical decision to a core strategic one that impacts cost, efficiency, and operational reliability.

For any large-scale industrial project, the primary gateway to Madagascar is the Port of Toamasina (also known as Tamatave). It is the country’s largest and most important commercial port, handling approximately 80% of the nation’s cargo traffic. Its deep-water facilities can accommodate the large container vessels needed to carry essential solar manufacturing equipment and raw materials.

It’s also worth noting the ongoing Port of Toamasina Extension Project. Financed with support from the Japan International Cooperation Agency (JICA), this development is set to increase container capacity and modernize operations. This forward-looking investment shows a commitment to improving logistical efficiency—a positive indicator for any long-term business plan.

This makes Toamasina the most reliable and scalable entry point for importing the necessary machinery for turnkey solar module manufacturing lines and securing a continuous flow of production materials.

Analyzing the Toamasina-Antananarivo Corridor: The Economic Artery

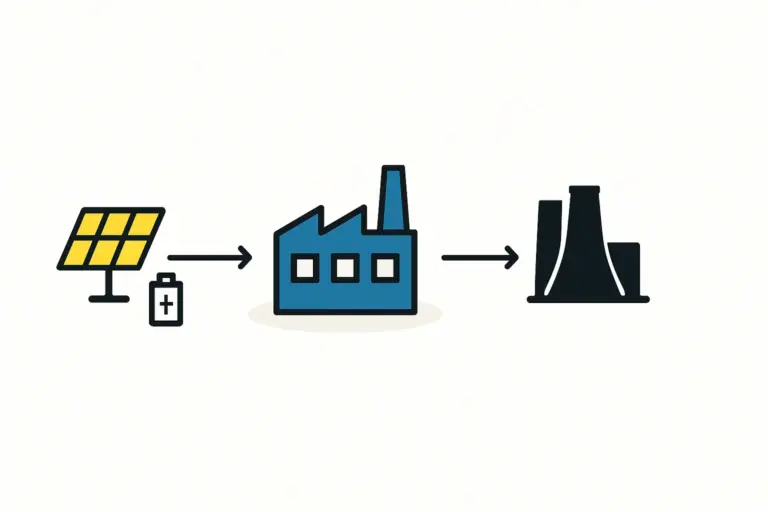

Once goods are cleared at the port, the next challenge begins: inland transport. The most critical route in Madagascar is the corridor connecting the Port of Toamasina to the capital, Antananarivo, where much of the country’s industrial and commercial activity is concentrated.

This corridor is served by two main channels:

-

Route Nationale 2 (RN2): This is the primary artery for freight transport, and the majority of containers and goods travel along this road. However, its condition can be variable. Congestion, seasonal wear, and potential damage during the rainy season (typically November to April) can lead to significant delays. A common oversight for new investors is assuming that quoted road transit times are consistent year-round.

-

The TCE Railway (Toamasina-Côte Est): A railway line runs parallel to the RN2, offering an alternative for transporting heavy goods. While it can be a viable secondary option, it currently faces challenges with capacity, scheduling reliability, and infrastructure limitations. It should be considered part of a contingency plan rather than a primary transport strategy.

Any logistics model for Madagascar must be built on the assumption of potential delays along this corridor. Factoring in buffer time and alternative solutions is not a sign of pessimism but of sound operational planning.

Core Logistical Challenges and Strategic Solutions

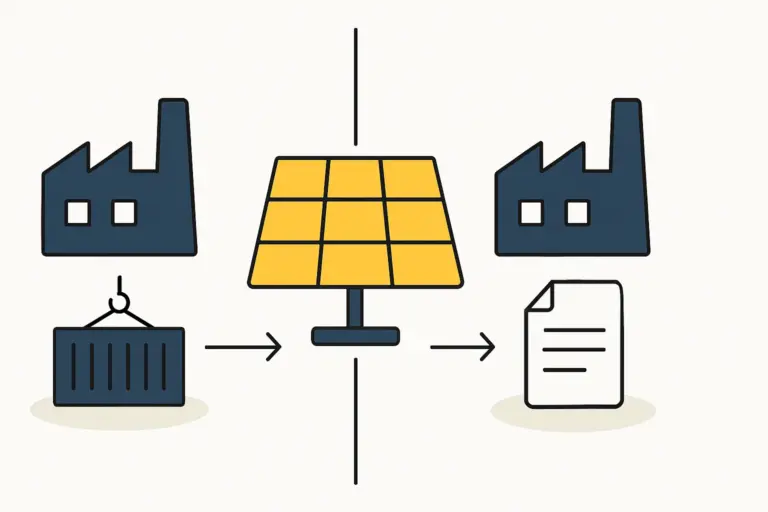

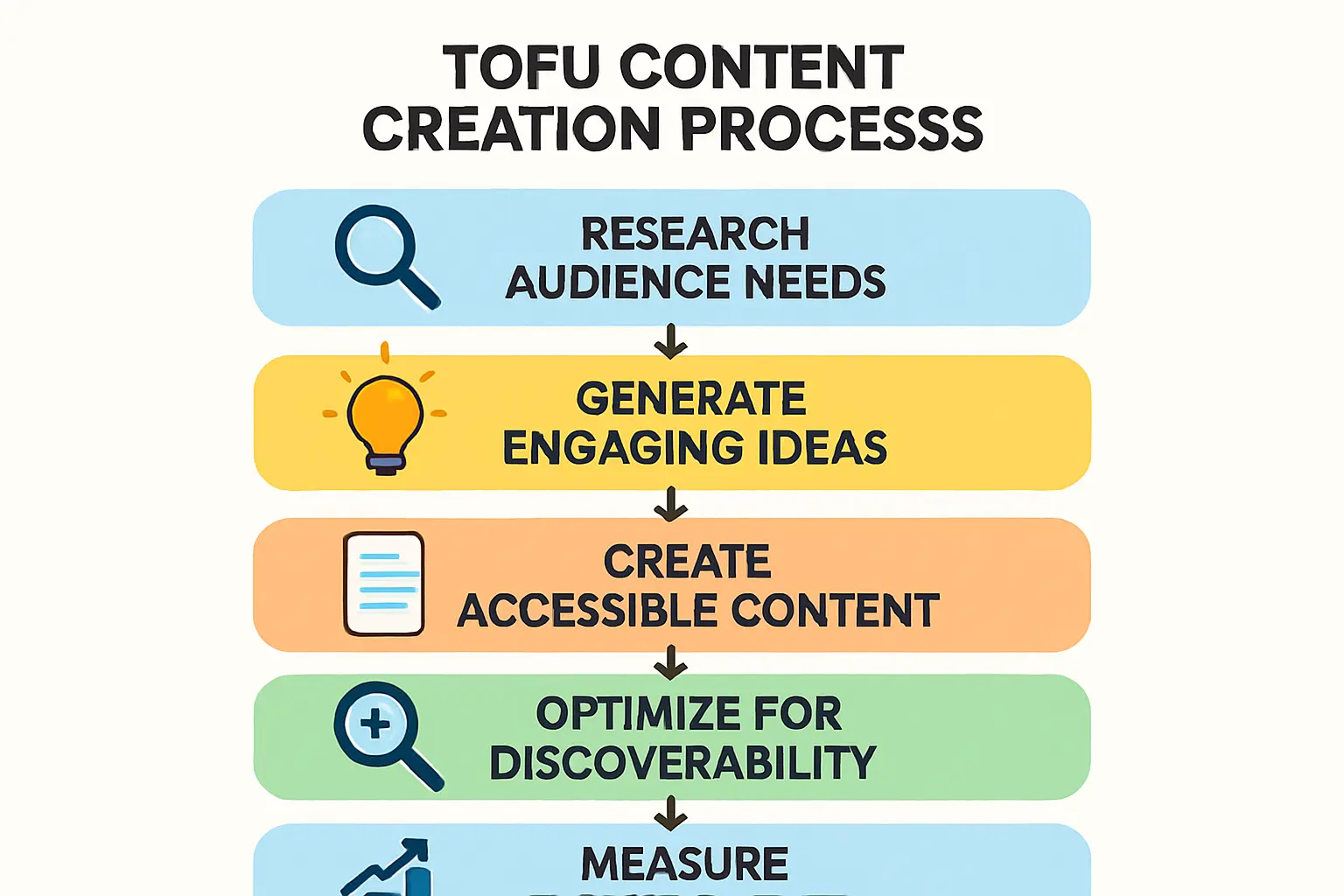

A successful solar manufacturing operation in Madagascar demands a proactive approach to logistics. The primary challenges involve inbound supply, inland transport conditions, and the outbound distribution of finished products.

Inbound Logistics: Securing Raw Material Flow

A solar module factory is fundamentally an assembly operation that relies on a consistent influx of imported components. Securing a steady supply of raw materials for solar panel production—from photovoltaic cells and encapsulants to glass and aluminum frames—is entirely dependent on efficient port operations and reliable inland transport.

Strategic Solution: Establish a robust inventory management system with sufficient buffer stock. Holding two to four weeks of critical raw materials at a secure warehouse, either near the port or at the factory site, can absorb the impact of shipping or transport delays. The cost of this buffer stock must be factored into the initial working capital requirements of the business plan.

Inland Transport: Navigating the ‘Last Mile’

While the RN2 corridor is the main economic lifeline, the quality of Madagascar’s road network deteriorates significantly beyond the main national routes. Transporting raw materials to a factory or, more importantly, distributing finished modules to rural or remote project sites is a formidable challenge. Unpaved roads, inadequate bridges, and seasonal impassability during the rainy season are common issues.

Strategic Solution: The physical location of the factory becomes a critical logistical decision. Locating the facility with direct access to a major, well-maintained transport route can dramatically reduce operational friction and cost. This is a key factor in the solar factory building requirements and site selection process. Partnering with experienced, local logistics providers who have a proven track record of navigating these challenging conditions is also essential.

Outbound Logistics: Distributing Finished Modules

Solar modules are relatively large and fragile. Transporting them across difficult terrain requires specialized handling and packaging to prevent damage. The challenge of distributing finished panels to installation sites, especially for rural electrification projects, is a significant operational hurdle.

Strategic Solution: A ‘hub-and-spoke’ distribution model can be effective. This involves shipping modules in bulk from the factory to secure, regional warehouses (hubs). From these hubs, smaller, more agile vehicles can be used for final delivery to project sites (spokes). This approach minimizes the risk of damage on long-haul journeys over poor roads and allows for more flexible delivery scheduling.

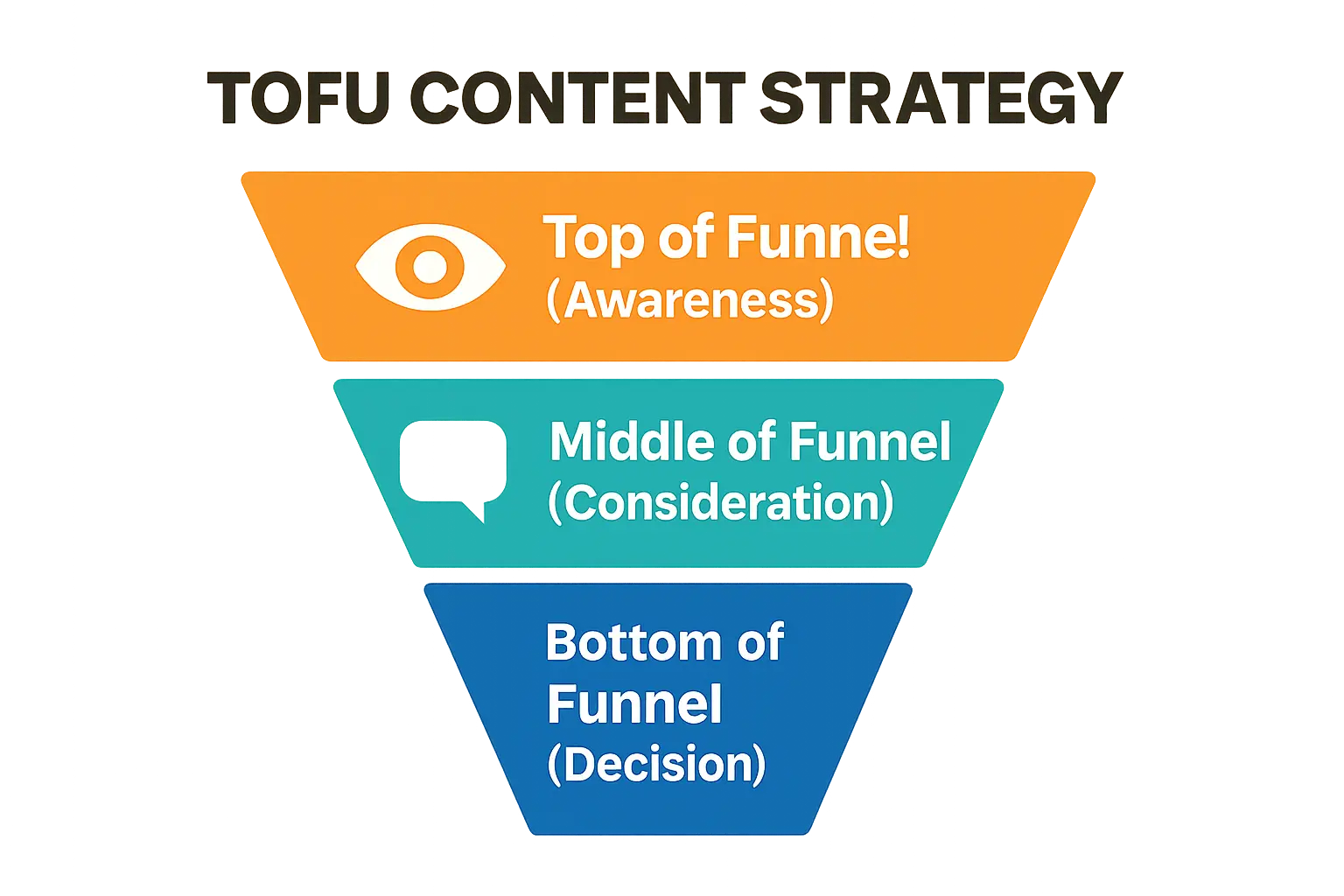

A Framework for Your Madagascar Logistics Strategy

Based on experience from J.v.G. turnkey projects in regions with similar infrastructure challenges, a detailed logistical plan is as critical as the production line design itself. Your strategy should address four key areas:

-

Integrated Siting: Analyze the trade-offs between locating your factory near the Port of Toamasina (streamlining raw material imports) versus near Antananarivo (closer to a major market and labor pool). The optimal choice depends on your specific business model.

-

Multi-Modal Transport Planning: Develop a primary logistics plan based on road transport via the RN2, but include a contingency plan that incorporates rail transport or alternative routing.

-

Seasonal Resilience: Your operational plan must account for the rainy season. This includes increased inventory levels, flexible production scheduling, and communication protocols with logistics partners to manage expected delays.

-

Local Expertise: Engage with reputable local customs brokers, freight forwarders, and transport companies early in the planning process. Their on-the-ground knowledge is invaluable and can help avoid costly mistakes.

Frequently Asked Questions (FAQ)

Why is Toamasina the recommended port for a solar factory?

Toamasina is Madagascar’s largest deep-water port, handling the vast majority of its international cargo. Its capacity to receive large container ships and its ongoing expansion make it the only truly viable option for importing heavy manufacturing equipment and a continuous supply of raw materials at scale.

How significant is the impact of the rainy season on logistics?

The impact is substantial. Heavy rains from November to April can make secondary roads impassable and cause significant delays on primary routes like the RN2 due to flooding or damage. It’s essential to plan for potential transport delays measured in days, or even weeks, during the peak of the season.

Is it better to locate the factory near the port or near the capital?

There are trade-offs. A location near Toamasina simplifies the import of raw materials and reduces the risk of inland transport disruptions affecting production. A location near Antananarivo places the factory closer to a major domestic market, government offices, and a larger labor pool. A detailed feasibility study is required to determine the optimal choice for your specific project.

What are the first steps in developing a logistics plan for Madagascar?

The first step is to conduct a thorough feasibility study with a strong focus on infrastructure and logistics. This should involve mapping potential supply routes, vetting local logistics partners, and modeling the costs and timelines associated with different transport scenarios, including seasonal variations.

Ultimately, navigating the logistical landscape of Madagascar is a challenge that can be successfully managed with diligent, upfront planning. By treating the supply chain with the same importance as the production line, entrepreneurs can build a resilient foundation for a successful solar manufacturing venture, capable of meeting the growing energy demands of the nation.