Madagascar has one of the world’s most favorable climates for solar energy, with an average solar irradiation of nearly 2,800 kWh per square meter annually. Yet, the country faces a striking paradox: its electricity access rate is among the lowest in the world.

For an entrepreneur, this gap between immense natural resources and unmet energy demand presents a clear business opportunity. This analysis explores Madagascar’s market dynamics and outlines how a local solar module factory can be strategically positioned to serve two distinct customer segments: the vast off-grid rural population and the energy-dependent commercial sector.

Understanding Madagascar’s Dual Energy Landscape

The demand for solar energy in Madagascar is not monolithic. It stems from two separate sources, each with its own unique requirements and challenges. A successful manufacturing strategy must address both.

The Rural Electrification Imperative

According to recent data, only 33.7% of Madagascar’s population has access to electricity. In rural areas, this figure plummets to just 19%. As a result, millions of households rely on expensive and inefficient alternatives, such as kerosene lamps for lighting and diesel generators for minimal power.

The Malagasy government, through its New Energy Policy and institutions like the Rural Electrification Agency (ADER), is actively promoting decentralized renewable energy solutions to bridge this divide. This policy support creates a stable market for Solar Home Systems (SHS) and micro-grids—often the most practical and cost-effective way to bring power to remote communities.

The Commercial & Industrial (C&I) Drive for Independence

For businesses in Madagascar, particularly in key sectors like textiles, tourism, and agribusiness, the unreliable grid and high cost of diesel fuel are major operational hurdles. Many companies depend on diesel generators to ensure continuous operation, exposing them to volatile fuel prices and significant maintenance expenses.

For this segment, solar PV is more than an environmental choice—it is a strategic business decision. It offers a clear path to energy independence, predictable operational costs, and long-term savings. Businesses are increasingly investing in rooftop or ground-mounted solar installations to secure their power supply and improve their bottom line.

The Strategic Advantage of Local Solar Module Production

Currently, nearly all solar modules installed in Madagascar are imported. This reliance on foreign supply chains creates several challenges that a local manufacturer can turn into a competitive advantage:

- Logistical Hurdles: Importing goods to an island nation involves complex shipping, port delays, and high transportation costs.

- Import Duties & Taxes: Tariffs can significantly increase the final cost of imported panels, making them less accessible.

- Currency Fluctuation: Purchasing modules in foreign currencies (USD or EUR) exposes projects to exchange rate risks.

A local factory can directly address these issues, offering faster delivery, greater price stability, and products tailored to the Malagasy market.

Configuring a Production Line for a Two-Tier Market

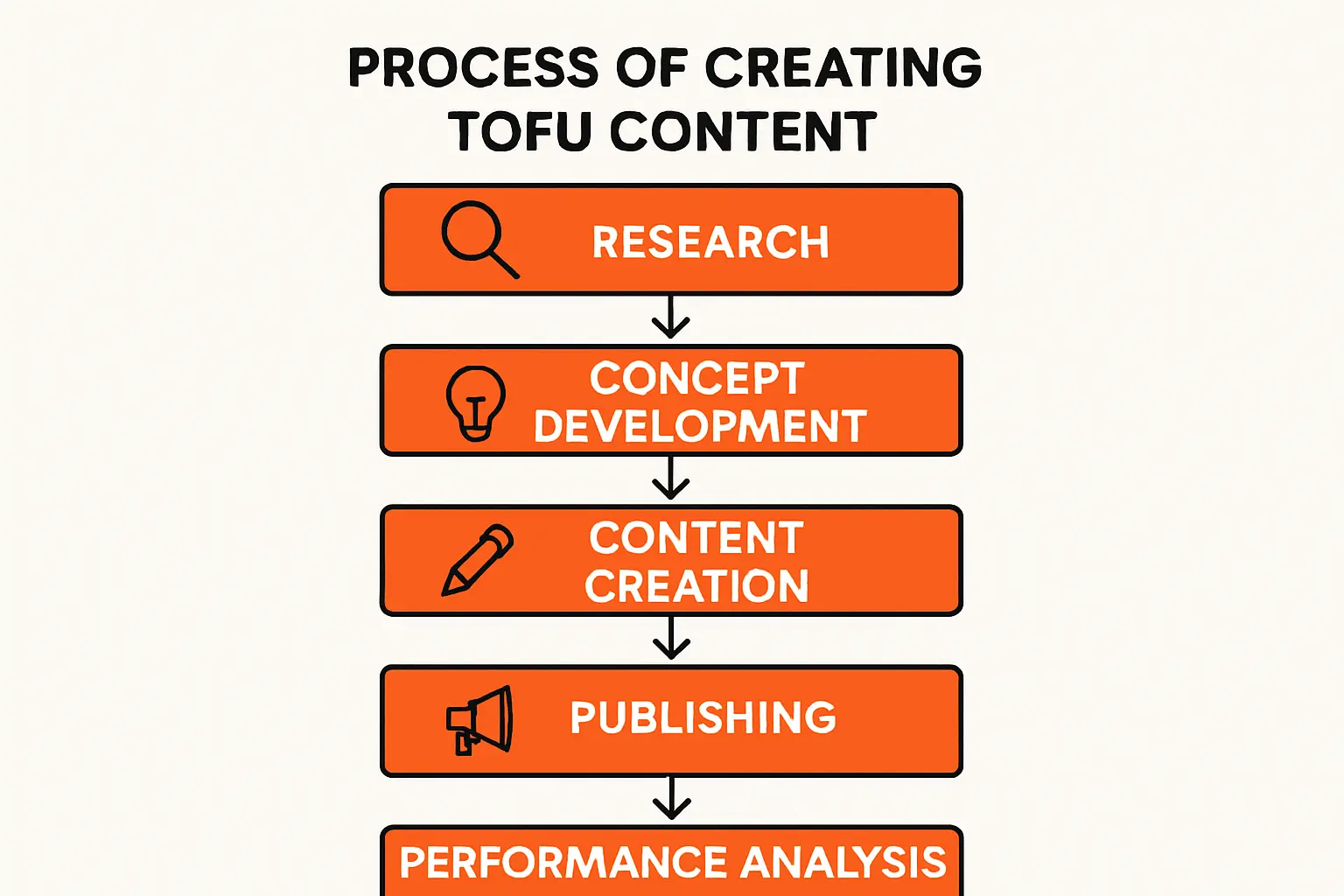

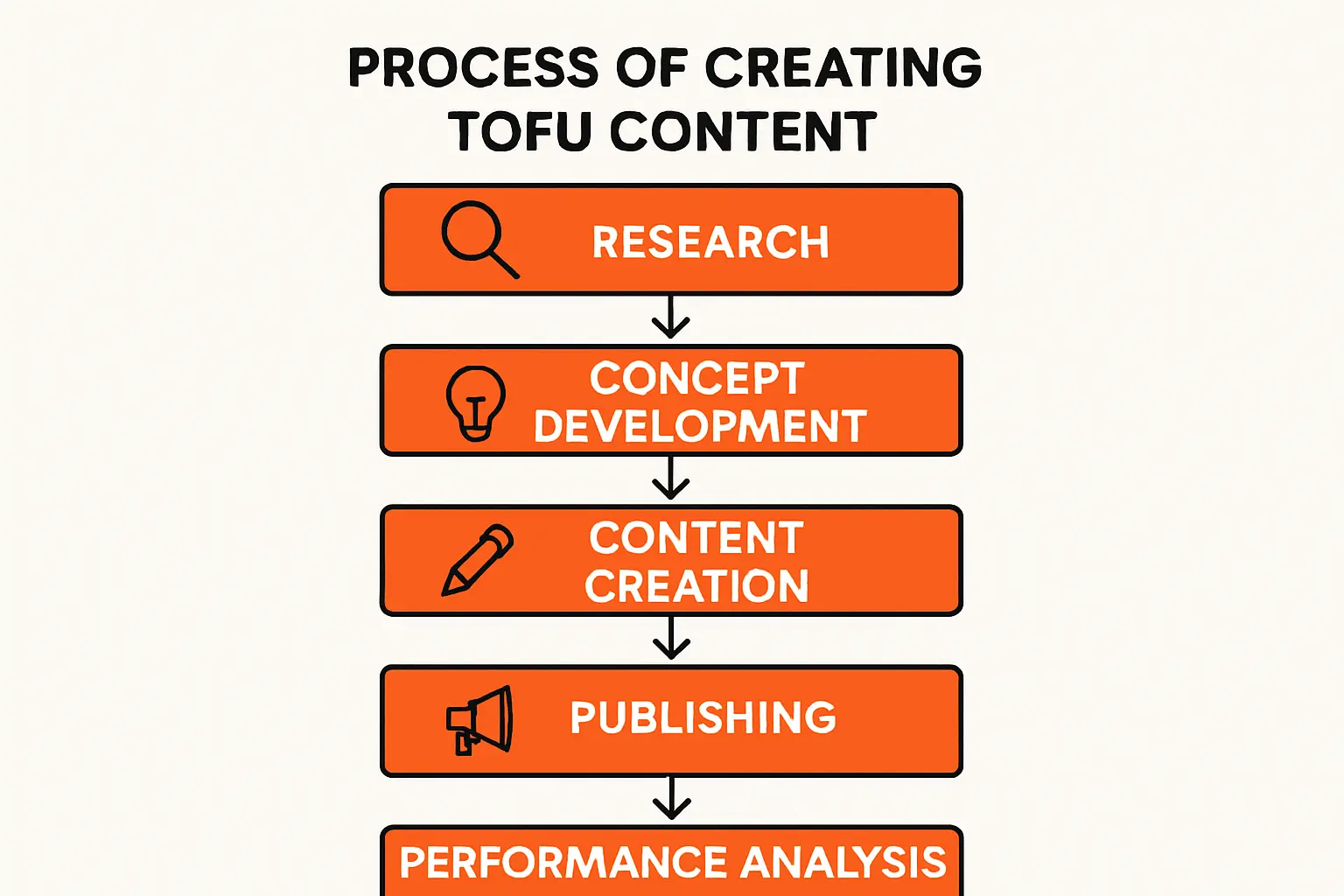

An investor does not need to choose between serving the rural or commercial market. A modern, semi-automated solar panel production line can be flexibly configured to produce modules for both segments. The key is to understand their distinct product requirements.

Product Strategy 1: Modules for Off-Grid Solar Home Systems (SHS)

The primary need in rural markets is for affordable and durable modules to power basic household systems. These systems typically include a panel, a battery, LED lights, and a port for charging mobile phones.

Module Configuration:

- Size & Power: Smaller wattage panels (e.g., 50W to 150W) are ideal, as they are easier to transport over difficult terrain and their cost aligns with the purchasing power of rural households or micro-financing programs.

- Durability: The construction must be robust enough to withstand challenging transport conditions and varying weather patterns, including high humidity and strong sun.

- Technology: Proven, reliable cell technologies are prioritized over the highest possible efficiency to keep the final product affordable.

Planning this type of production requires a detailed solar panel manufacturing business plan that accounts for material sourcing and distribution logistics to reach remote areas effectively.

Product Strategy 2: Modules for the Commercial & Industrial (C&I) Sector

Businesses investing in solar installations require modules that maximize energy production and deliver a reliable return on investment over a 25-year lifespan.

Module Configuration:

- Size & Power: Standard format modules (e.g., 60-cell or 72-cell equivalents) with higher power outputs are preferred to maximize energy generation on limited rooftop or land space.

- Efficiency: Higher-efficiency cells are crucial, as they generate more power per square meter, reducing the overall project footprint and balance-of-system costs.

- Certifications: Modules must meet international quality and safety standards (e.g., IEC certifications) to be considered ‘bankable’ for project financing.

The Flexibility of a Modern Production Line

The core equipment within a solar factory—such as the stringer, laminator, and solar simulator—can be adjusted to process different cell sizes and module configurations. The flexibility to switch between producing a 100W off-grid panel and a 450W commercial panel is a core design feature.

This adaptability stems from the solar panel manufacturing machine list chosen for the factory setup. By investing in versatile machinery from the outset, a manufacturer can pivot production based on market demand.

A Practical Look at Implementation

For those new to the sector, understanding how to start a solar panel factory from a strategic perspective is the crucial first step. A common entry point is a semi-automated line with an annual capacity of 20 to 50 MW. Such a facility requires a staff of 25–35 employees and can be housed in a building of approximately 2,000 square meters.

Experience from J.v.G. turnkey projects in emerging markets shows that a phased approach is often effective. A new enterprise could begin by focusing on one product type to establish its brand and distribution channels, then expand its portfolio to serve the other market segment.

Frequently Asked Questions (FAQ)

What is the primary driver for solar in Madagascar?

There are two primary drivers: the urgent need for electricity access in vast rural areas and the economic necessity for businesses to secure a reliable, cost-effective alternative to expensive diesel fuel.

Is it better to produce small or large modules?

Neither is inherently better; they serve two different, equally valid markets. Small modules (50-150W) are for off-grid residential use, while larger modules (400W+) are for commercial projects. A flexible production line that can produce both offers the greatest market reach.

Do I need a massive factory to start?

No. A large, fully automated ‘gigafactory’ is not necessary or advisable for entering a market like Madagascar. A semi-automated line with a capacity of 20 MW to 50 MW is a common and financially viable starting point that aligns with the current market size.

Are there government incentives for local production?

The Malagasy government’s New Energy Policy and its support for rural electrification signal a favorable environment for investment in local renewable energy manufacturing. Specific incentives may be available and should be investigated as part of the business planning process.

Conclusion: From Market Need to Manufacturing Reality

Madagascar’s energy landscape presents a clear and compelling case for local solar module manufacturing. The demand is not speculative; it is rooted in the fundamental daily needs of millions of households and the operational necessities of its core industries.

By understanding the distinct requirements of the off-grid and commercial sectors, an entrepreneur can configure a flexible and efficient production facility. This approach not only creates a profitable business venture but also contributes directly to the country’s economic development and energy independence.