An investor planning a new solar module factory often focuses on machinery, buildings, and balance sheets. Yet, a critical question frequently arises late in the process: ‘Where will we find people with the right skills to operate this advanced equipment?’

In a market like Madagascar, with its developing industrial base, this concern is understandable. It is not, however, an insurmountable barrier. Instead, it’s a manageable challenge that, when addressed strategically, can become a significant competitive advantage.

The first misconception is assuming you must find a pre-existing pool of experienced solar technicians. The reality, confirmed by numerous J.v.G. turnkey projects in emerging markets, is that the most successful ventures build their workforce from the ground up. Madagascar’s young population—with a median age of just 19.6 years and a national literacy rate over 76%—represents a vast, motivated talent pool ready for training. The key is not to find experts, but to create them through a structured, systematic process.

Core Competencies: Identifying the Right Aptitudes for Recruitment

Instead of searching for specific solar manufacturing experience, recruitment should focus on identifying candidates with the right inherent aptitudes. These foundational traits are far more critical for long-term success and quality control than specific work experience.

Manual Dexterity and Attention to Detail

Solar module assembly involves handling delicate components with precision, like solar cells that are often less than 0.2 mm thick. Operators must work carefully and consistently to avoid microcracks and ensure flawless soldering. Ideal candidates often come from backgrounds requiring fine motor skills, such as electronics repair, textiles, or detailed craftwork. Simple practical tests during interviews can effectively assess a candidate’s dexterity and concentration.

Process Discipline

A modern solar production line is a highly standardized environment with strict quality control protocols. The ability to follow multi-step instructions precisely, every single time, is non-negotiable for achieving product certification and ensuring reliability. Candidates who demonstrate a methodical, disciplined approach to tasks are highly valuable, as this mindset is essential for maintaining the integrity of the manufacturing process.

Technical Curiosity and Problem-Solving

While operators focus on execution, a successful team also needs individuals with a natural curiosity for how things work—these are your potential team leaders and maintenance staff. They are crucial for identifying minor process deviations, performing routine machine maintenance, and troubleshooting issues before they cause significant downtime. This aptitude for basic problem-solving is a strong indicator of leadership potential within the factory.

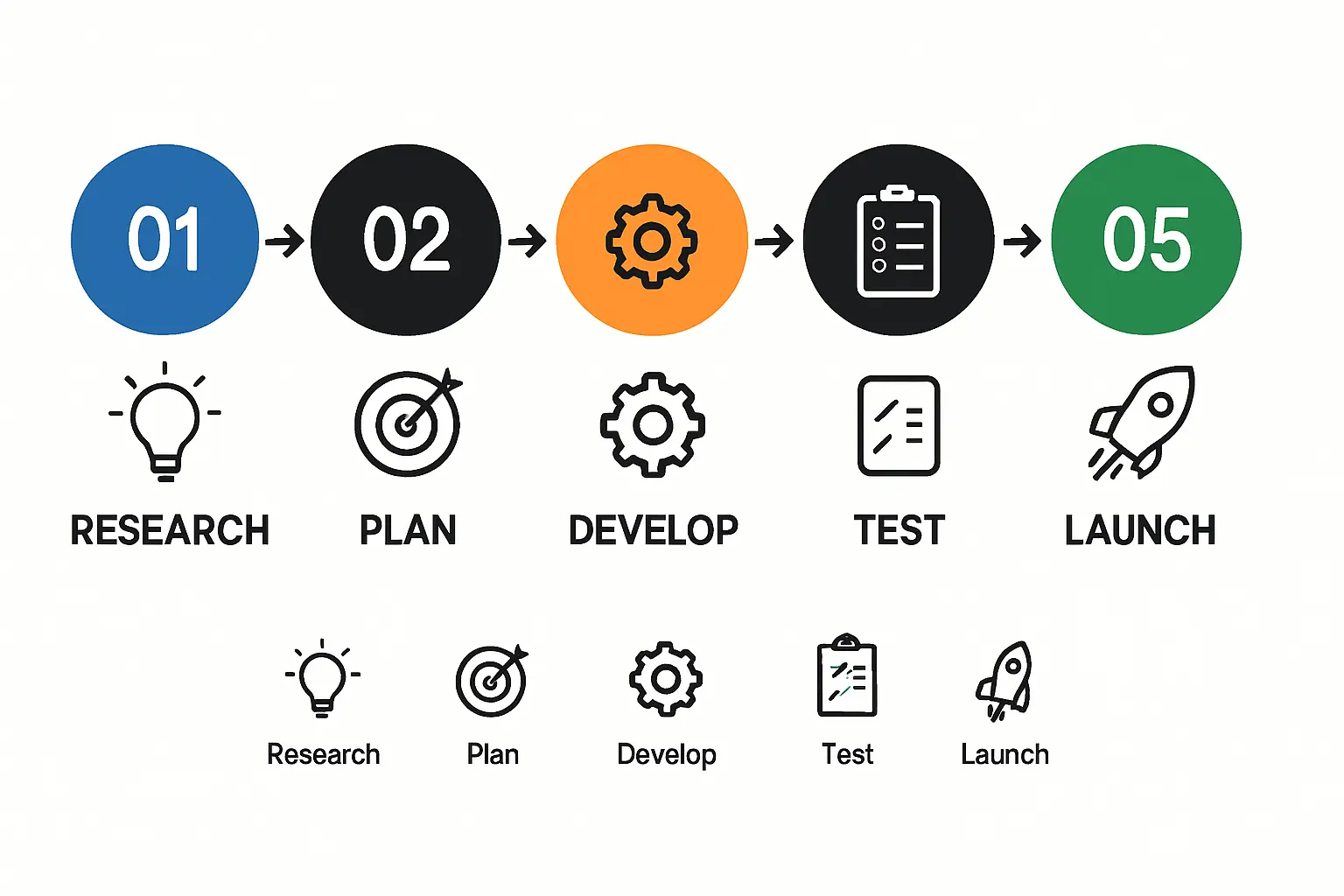

A Phased Training Framework: From Novice to Qualified Technician

A well-designed program can transform motivated but inexperienced individuals into a proficient technical team in just a few months. A phased approach ensures a logical progression from theory to practical application.

Phase 1: Foundational Knowledge (Weeks 1-2)

This initial phase takes place in a classroom. The curriculum should cover the essential theory needed to work safely and effectively in the factory. Key topics include:

- Introduction to Photovoltaics: A basic understanding of how solar cells work and how a module is constructed.

- Safety Protocols: Comprehensive training on electrical safety, material handling, and emergency procedures.

- Quality Standards: An introduction to quality control concepts and the importance of each step in the solar panel production line.

- Machine Functions: An overview of each piece of equipment and its role in the assembly process.

Phase 2: Supervised Hands-On Training (Weeks 3-8)

After classroom instruction, trainees move to the production floor. Under the close supervision of experienced trainers—often provided by the turnkey line supplier—each new employee rotates through every station. This hands-on practice is critical for developing muscle memory and a deep understanding of the workflow. Trainees practice tasks on each machine, from the stringer to the laminator, until they can meet both speed and quality benchmarks.

Phase 3: Specialization and Upskilling (Ongoing)

Once the team achieves baseline proficiency, high-potential individuals can be identified for specialized training. This approach creates career progression pathways and builds a robust internal support structure. Specific roles for upskilling include:

- Quality Control Inspectors: Trained in visual inspection techniques, electroluminescence (EL) image analysis, and performance testing.

- Machine Maintenance Technicians: Given in-depth mechanical and electrical training on key equipment, such as understanding the difference between a stringer and a bussing machine.

- Team Leaders: Trained not only in the technical process but also in leadership, communication, and production reporting.

Leveraging Local Partnerships for Sustainable Talent Development

Building a skilled workforce shouldn’t happen in a vacuum. By integrating the factory into the local educational ecosystem, a company can create a sustainable talent pipeline that benefits both the business and the community.

Collaboration with Technical and Vocational Schools

Establishing a formal partnership with one or more of Madagascar’s technical and vocational training institutions can be highly effective. The company can advise on curriculum development to align it with industry needs, offer internships to promising students, and establish itself as a preferred employer for graduates. This proactive approach reduces long-term recruitment challenges and demonstrates a commitment to local development, which can also be beneficial when dealing with government bodies.

The ‘Train the Trainer’ Model

For long-term autonomy, the ‘train the trainer’ model is an industry best practice. During the initial factory setup and commissioning, the equipment supplier’s experts provide intensive training to a core group of local hires selected for their leadership potential. This group becomes the in-house training team, responsible for onboarding all future employees. This model ensures that expert knowledge is retained within the company and allows training to be delivered in the local language and cultural context, making it more effective and scalable.

FAQ: Common Questions on Building a Solar Manufacturing Workforce

How many employees are needed for a small-scale (20-50 MW) factory?

A typical semi-automated line of this capacity requires approximately 25 to 35 employees per shift. This includes machine operators, quality control staff, maintenance technicians, logistics personnel, and administrative support.

What is the typical timeframe to get a new team production-ready?

With a structured training program, a core team can be trained and ready to begin initial, supervised production within 8 to 12 weeks. Reaching full production capacity and efficiency typically takes an additional 3 to 6 months.

Is a technical university degree required for operators?

No. For machine operator positions, a secondary school education is generally sufficient. The most important qualifications are the aptitudes discussed earlier: dexterity, discipline, and a willingness to learn. Higher educational qualifications, such as a technical diploma or engineering degree, are typically required for roles in quality management, process engineering, and senior maintenance.

How does language impact the training process?

While Malagasy and French are the official languages of Madagascar, ensuring key personnel (team leaders, engineers) have a working proficiency in English is a significant advantage. This facilitates direct communication with international equipment suppliers and certification bodies. For operators, all training materials and machine interfaces should be translated into the local language to ensure clarity and reduce errors.

From Blueprint to Reality: Your Next Steps

Building a skilled, local workforce for a solar module factory in an emerging market isn’t a matter of luck, but of methodical planning. It begins by shifting the focus from finding existing experience to identifying raw potential. By implementing a phased training framework and fostering local educational partnerships, an investor can build a capable, loyal team that becomes the foundation for quality production and long-term success.

This investment in human capital is as critical as the investment in machinery. The next logical step is to ensure the physical environment supports this new team. Understanding the building requirements for a solar factory is essential for creating a safe, efficient workspace where a well-trained workforce can thrive. Educational platforms like pvknowhow.com offer detailed guidance, including sample training plans and organizational charts, to help new market entrants navigate this process effectively.