Malta’s strategic Mediterranean location and access to European markets make it an attractive prospect for investors planning a new solar module manufacturing facility. A successful project, however, is built not just on market access, but on navigating the local regulatory landscape. For those unfamiliar with the Maltese system, securing the necessary permits can appear complex.

This guide provides a clear, step-by-step overview of the administrative and environmental approval processes in Malta. It is designed to help business professionals understand the key authorities, anticipate requirements, and forecast project timelines, making a potential hurdle a manageable part of the business plan.

Understanding Malta’s Dual-Authority System

The Maltese regulatory framework for industrial development is managed by two distinct yet interconnected bodies: the Planning Authority (PA) and the Environment and Resources Authority (ERA).

The Planning Authority (PA)

This authority oversees land use and development. Its primary concern is ensuring that any proposed construction aligns with national planning policies, zoning regulations, and building standards. For a solar factory, the PA will assess the building’s design, size, location, and its impact on the surrounding infrastructure.

The Environment and Resources Authority (ERA)

The ERA focuses exclusively on safeguarding the environment by evaluating the factory’s potential operational impact. This includes assessing air and water emissions, waste generation, noise levels, and the use of natural resources.

Investors must understand that these are not sequential steps but are often parallel processes. A development permit from the PA is needed to build the structure, while an environmental permit from the ERA is required to operate it legally.

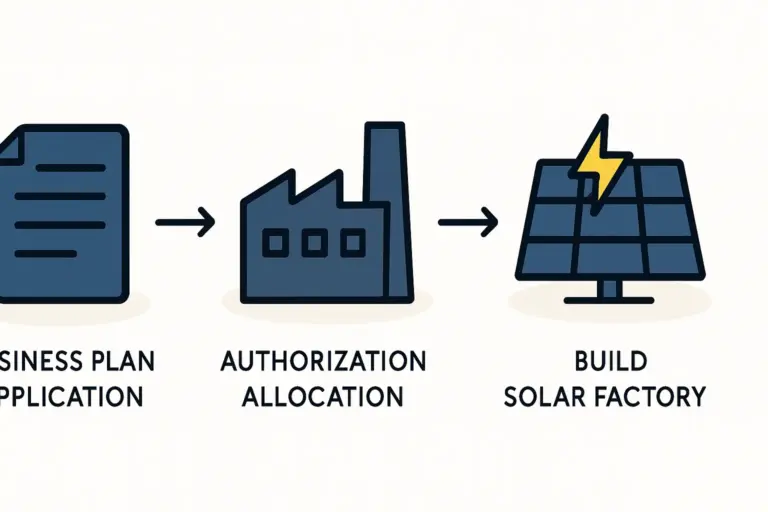

The Planning Authority (PA) Development Permit: A Step-by-Step Pathway

Securing a development permit from the Planning Authority is a structured, multi-stage process. Engaging a local, warranted architect (Perit) is not just recommended—it is mandatory for navigating this system.

Stage 1: Pre-Application and Screening

The process begins with an initial submission to the PA, during which the project architect provides preliminary details about the proposed factory. The PA screens this information to determine the correct application track and identify any major planning issues early. This initial engagement is crucial for setting the project on the right course and understanding the full scope of requirements.

Stage 2: Application Submission and Validation

After incorporating pre-application feedback, a formal application is submitted. This package includes detailed architectural drawings, site plans, and supporting documents that demonstrate compliance with all relevant planning policies. The PA then undertakes a validation process, a formal check to ensure the application is complete and contains all necessary information. This stage assumes an investor has a clear plan for the facility, from the layout of the turnkey solar manufacturing line to the logistical flow of materials.

Stage 3: Public Consultation and Assessment

Following validation, the application enters a public consultation period, typically lasting 30 days. During this time, the public and other government bodies can review the proposal and submit comments. At the same time, a designated PA case officer conducts a thorough assessment, which culminates in a report and recommendation for the decision-making body.

Stage 4: Decision and Post-Decision Matters

The final decision is made by the Planning Commission or Board, based on the case officer’s report and any feedback received. The outcome could be approval (often with specific conditions), refusal, or a request for modifications. If a permit is granted, there is a period during which third parties can appeal the decision. Once this appeal period passes and the permit becomes final, construction can begin.

Navigating the Environment and Resources Authority (ERA) Permit

Parallel to the PA process, the investor must secure approval from the ERA. This ensures the plant will operate within strict environmental limits, a standard practice across the European Union.

The Environmental Impact Assessment (EIA) Screening

A project of this nature—an industrial manufacturing plant—will almost certainly require an EIA screening, as stipulated in Schedule I of the EIA Regulations (S.L. 549.46). The investor submits a Project Description Statement (PDS) detailing the factory’s processes, raw materials, and potential environmental outputs. Based on this, the ERA will determine one of two outcomes:

-

No Full EIA Required: If the potential impact is deemed minimal, the project can proceed to the next stage of environmental permitting without an in-depth study.

-

Full EIA Required: If the project is likely to have significant environmental effects, the ERA will mandate a comprehensive Environmental Impact Assessment. This is a detailed study conducted by independent consultants, which can add considerable time and cost to the project planning phase.

Industrial Emissions Regulations and the IPPC Permit

Solar module manufacturing involves chemical processes and generates specific types of waste, placing it under the Industrial Emissions Regulations. As a result, the factory will require an Integrated Pollution Prevention and Control (IPPC) permit to operate. This permit sets legally binding limits on emissions to air and water, outlines waste management protocols, and mandates energy efficiency and monitoring measures. Applying for an IPPC permit is a detailed technical undertaking that requires specialist environmental input.

Waste Management Considerations

A key area of scrutiny for the ERA will be the factory’s waste management plan. This document must detail how various waste streams—from broken glass and silicon to used chemicals and packaging materials—will be segregated, stored, and disposed of or recycled in accordance with EU and Maltese law.

Strategic Considerations for Investors

Successfully navigating this regulatory landscape requires more than just following procedures; it demands strategic planning from the outset.

Site Selection within Designated Industrial Zones

In Malta, choosing the right location for a solar factory is critically important. Establishing the plant within a government-designated industrial zone, such as the Bulebel or Hal Far Industrial Estates, can significantly streamline both the planning and environmental permitting processes. These areas are already zoned for industrial use, simplifying the PA assessment and often meaning that baseline environmental studies are already available.

Realistic Project Timelines

Investors must plan for a realistic administrative timeline. Based on experience from J.v.G. turnkey projects, accurately forecasting this phase is critical for managing capital and stakeholder expectations. A straightforward application with no EIA might take 6 to 12 months to clear. However, if a full EIA is required, the permitting process could extend to 18 months or more.

The Importance of Local Expertise

The Maltese system has its own local practices. Attempting to manage the permitting process without qualified local professionals—specifically a Perit for the PA application and an environmental consultant for the ERA submissions—is impractical and highly likely to result in significant delays or even refusal. Their expertise is essential for preparing compliant documentation and liaising effectively with the authorities.

Frequently Asked Questions (FAQ)

What is the primary difference between the PA and ERA permits?

The Planning Authority (PA) permit concerns the physical development—the permission to build the factory structure. The Environment and Resources Authority (ERA) permit, in contrast, governs the factory’s operations—the permission to run manufacturing processes within environmental limits. An investor needs both.

Can the PA and ERA processes be done simultaneously?

Yes, they are typically handled in parallel. The authorities consult with each other throughout the assessment. For instance, the PA will not issue a final development permit for a project that the ERA has flagged as having insurmountable environmental issues.

How much should an investor budget for permitting fees?

Fees vary significantly based on the project’s scale and complexity. They include application fees for both the PA and ERA, as well as the professional fees for the required local architect and environmental consultants. If a full EIA is necessary, the cost for these specialized studies can be substantial. These costs should be considered a key part of the initial project budget.

Is a full Environmental Impact Assessment (EIA) always required for a solar factory?

Not automatically. An EIA is mandated only if the initial screening by the ERA determines that the project is likely to have a significant environmental impact. Given the nature of manufacturing, however, investors should be prepared for this possibility in their project planning.

Conclusion: Your Next Steps in Planning

Navigating Malta’s permitting pathway is a methodical process that rewards thorough preparation and expert guidance. The dual-authority system, while rigorous, is transparent and aligned with international best practices. By understanding the distinct roles of the Planning Authority and the Environment and Resources Authority, engaging local professionals early, and building realistic timelines, an investor can confidently move a project from concept to reality.

Understanding the regulatory pathway is a foundational step. For a broader overview of the entire setup process, the guide on how to start a solar module factory provides a comprehensive framework. Structured educational resources, such as those offered by pvknowhow.com, can further assist business professionals in organizing these complex planning stages for a successful entry into the solar manufacturing industry.