An entrepreneur can develop a comprehensive business model, secure funding, and source state-of-the-art machinery, only to overlook a fundamental driver of operational success: the cost and complexity of utility connections. For any high-consumption manufacturing facility, such as a solar module plant, understanding the nuances of electricity tariffs, water access, and grid integration isn’t a secondary detail—it’s a primary factor in financial viability and project timelines.

This article uses Malta’s specific regulatory environment as a practical case study to illustrate the critical due diligence required when planning a new industrial venture. The principles explored here—from multi-tiered electricity pricing to the procedural demands of a high-voltage grid connection—offer a valuable framework for entrepreneurs, regardless of their region.

Understanding Your Primary Operational Cost: Electricity

For a manufacturing plant, electricity is rarely a simple line item. It’s a significant and variable operational expenditure (OPEX) that directly impacts the cost of production per unit. A solar module factory, with machinery like laminators and stringers operating continuously, is classified as a high-consumption user. This status necessitates a direct connection to the high-voltage grid and a sophisticated understanding of the corresponding tariff structure.

Deconstructing Malta’s Non-Residential Electricity Tariffs

In Malta, the government-owned entity ARMS Ltd. manages utility billing. For an industrial user, the ‘High Voltage 11kV/33kV service’ tariff is the relevant framework. This structure is composed of several distinct charges, each requiring careful consideration in a financial model.

Service Charge: A fixed daily cost independent of consumption, set at €25.00 for high-voltage customers. This amounts to a predictable annual cost of €9,125 that must be factored into the baseline operational budget.

Consumption Charge: This is the variable cost for electricity used, measured in kilowatt-hours (kWh). The tariff is tiered, meaning the price per kWh decreases after a certain consumption threshold is met.

- First 50,000,000 kWh per year: €0.1298 per kWh

- Additional kWh per year: €0.1210 per kWh

For a factory with an annual consumption of 60,000,000 kWh, this calculation illustrates the importance of accurate forecasting.

Reactive Energy Charge: This technical but financially significant charge is, in simple terms, a penalty for inefficient electricity usage within the factory. Inductive loads from large motors can cause a mismatch between voltage and current, creating ‘reactive power’ that burdens the grid without performing useful work. This charge, set at €0.05 per kVArh for consumption exceeding 60% of the active power (kWh), incentivizes installing power factor correction equipment to improve efficiency.

Fuel Surcharge: This variable component is adjusted periodically to reflect the global cost of fuels used for power generation. It introduces market volatility into the electricity budget and underscores the need for contingency planning.

The Strategic Importance of a High-Voltage Connection

A facility consuming several million kWh annually cannot simply connect to the standard low-voltage network. It requires a dedicated connection to the high-voltage grid, a process that involves constructing a private substation on the factory premises. This substation houses the transformers and switchgear needed to step down high-voltage electricity (e.g., 11,000 Volts) to a usable level for the factory’s machinery (e.g., 400 Volts).

This requirement has two major implications for a business plan:

-

Capital Expenditure (CAPEX): The substation represents a significant upfront investment.

-

Project Timeline: The design, approval, and construction of this infrastructure is a lengthy process that must be integrated into the project’s earliest stages.

Securing a Critical Resource: Water Supply

While less complex than electricity, water access is another critical utility. In an island nation like Malta, where freshwater is scarce, most of the supply comes from energy-intensive reverse osmosis (RO). This production method is directly reflected in the commercial tariff managed by the Water Services Corporation (WSC).

The standard tariff for commercial and industrial use is a flat rate of €4.19 per cubic meter. Connecting to the WSC network involves a formal application process. Depending on the factory’s location and required flow rate, infrastructure upgrades may be necessary, creating potential costs and delays that must be investigated during the site selection phase.

The Critical Path: Navigating the Grid Connection Process with Enemalta PLC

Connecting a large industrial user to the national grid is a formal, multi-stage process managed by the grid operator, Enemalta PLC. This process forms a critical path in the overall project timeline, as no manufacturing can begin until a secure and stable power supply is established.

The Step-by-Step Connection Protocol

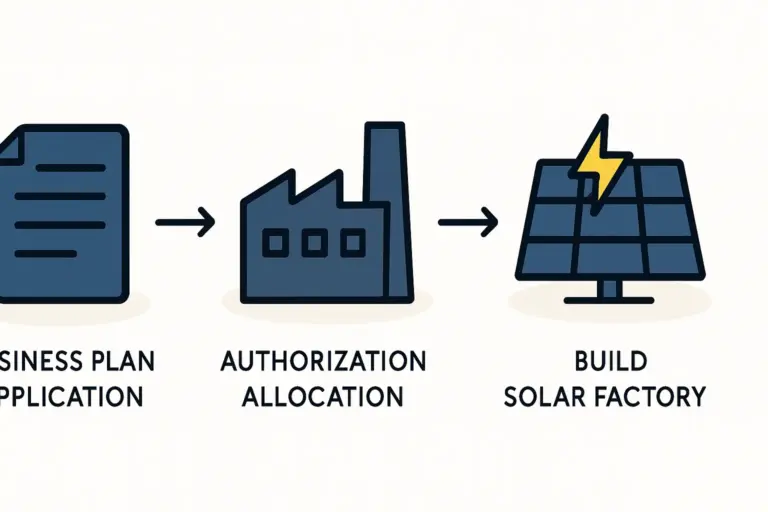

For any connection rated above 400kVA—a threshold easily surpassed by a solar factory—the following procedure applies:

-

Formal Application: The business submits a detailed application outlining its expected maximum power demand, consumption patterns, and the technical specifications of the planned facility.

-

Technical Feasibility Study: Enemalta engineers conduct a study to assess the new load’s impact on the area’s existing grid infrastructure. This study determines the technical solution for the connection.

-

Detailed Quotation: Following the study, Enemalta provides a comprehensive quotation. This quote covers not just the cable but the full scope of work, which may include trenching, cable laying, jointing, and any necessary upgrades to the public grid.

-

Agreement and Installation: Once the quotation is accepted and payment is made, the physical work is scheduled and executed. The entire process, from application to energization, can take several months and must be synchronized with the factory’s construction schedule.

Budgeting for the Unknown: Connection Costs

The cost of a grid connection is highly variable and site-dependent. A primary factor is the distance from the factory to the nearest suitable high-voltage node in Enemalta’s network. A location far from existing infrastructure will incur significantly higher costs for cabling and civil works. This financial uncertainty underscores why choosing the right site for your solar panel factory is one of the most important early decisions in the project.

Integrating Utility Planning into Your Business Model

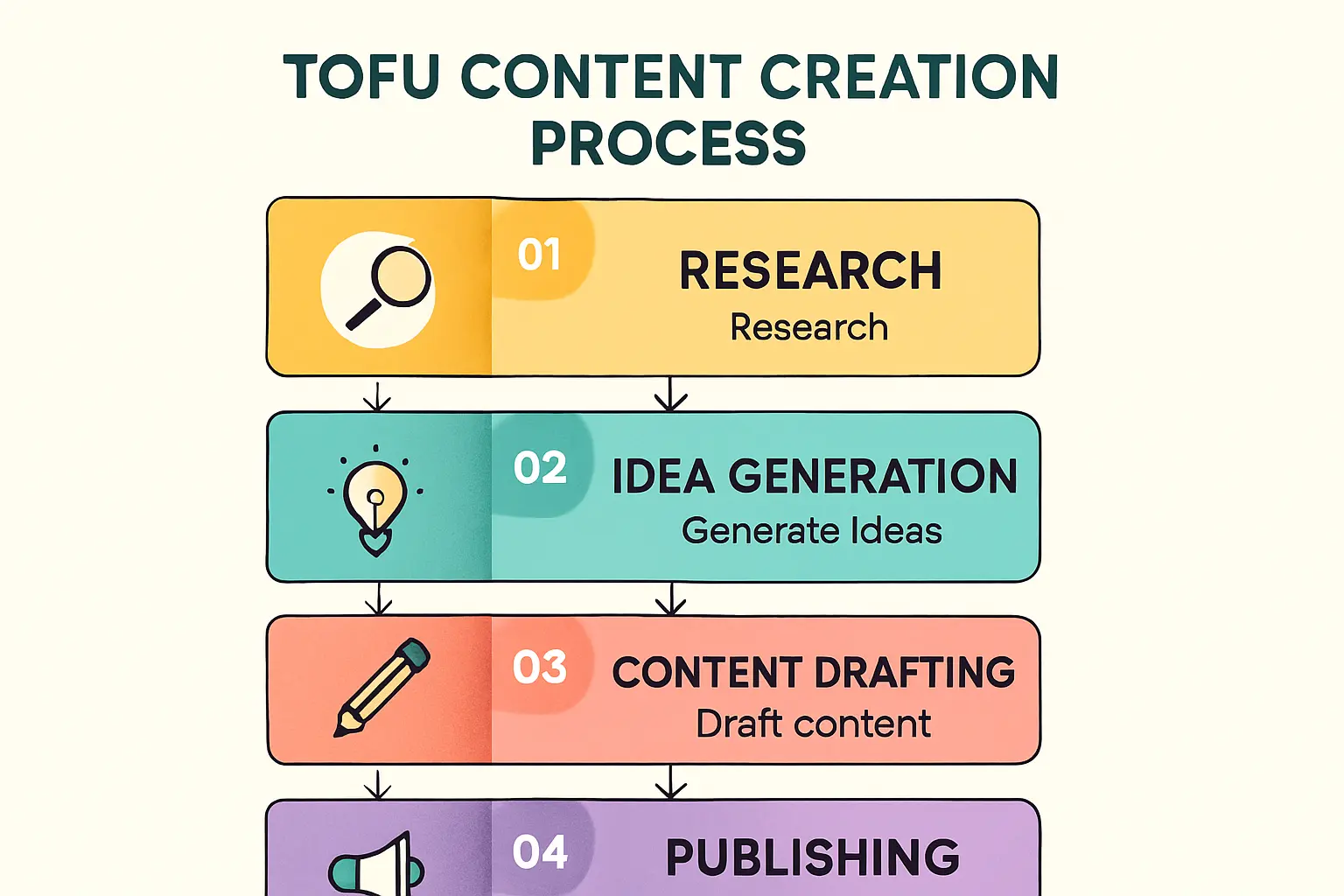

A thorough analysis of utility costs and connection protocols is a cornerstone of effective project planning. These factors must be integrated directly into financial projections and operational strategy. An accurate forecast of electricity costs, for example, is essential for creating a reliable solar panel manufacturing business plan.

Understanding the power requirements and sensitivities of the production line also influences decisions on which specific solar panel manufacturing equipment to procure. Based on experience from J.v.G. Technology GmbH turnkey projects, aligning machinery specifications with local grid conditions from the outset can prevent costly operational issues later on. A structured planning approach ensures these critical details are addressed methodically.

Frequently Asked Questions (FAQ)

Why is the electricity tariff for industrial users so complex?

The tariff structure is designed to reflect the costs associated with providing a large, stable supply of power. The fixed service charge covers the maintenance of dedicated infrastructure, while tiered consumption charges can incentivize large-scale industrial activity. Penalty charges, like the one for reactive energy, encourage users to operate efficiently, which in turn benefits the stability of the entire grid.

How early should a business start the grid connection process?

The grid connection process should begin as early as possible, ideally during the site selection phase. An initial consultation with the utility provider (Enemalta in this case) can provide preliminary feedback on the feasibility and potential costs for different locations—a decisive factor in the final site selection.

Are these utility costs and processes typical for other regions?

While the specific tariffs and regulatory bodies are unique to Malta, the underlying principles are universal. Any entrepreneur planning an industrial facility anywhere in the world must conduct similar due diligence. This includes identifying the utility provider, analyzing the commercial tariff structure, understanding the grid connection protocol, and budgeting for both operational costs and the upfront capital investment for the connection. This case study serves as a template for the type of research required.

What is a substation and why is it necessary for a factory?

A substation is a facility that uses transformers to ‘step down’ electricity from high voltage to a lower voltage. The national grid transmits power at very high voltages to minimize energy loss over long distances. A factory’s machinery, however, operates at a much lower voltage. The private substation acts as the interface, safely and efficiently converting the power to a usable form for the plant and ensuring the stable, high-capacity supply needed for industrial operations.

Conclusion: From Due Diligence to Operational Success

The journey from a business concept to a fully operational manufacturing plant demands meticulous planning. As the Malta case study demonstrates, utilities are not a simple expense but a strategic component of the business framework. The costs, timelines, and technical requirements associated with electricity, water, and grid connection can significantly influence a project’s budget, schedule, and ultimate profitability.

By treating utility planning with the same rigor as market analysis or equipment procurement, an entrepreneur builds a resilient foundation for long-term success. This detailed early-stage analysis is a hallmark of a well-prepared project and a crucial step in understanding how to start solar panel manufacturing on a solid footing.