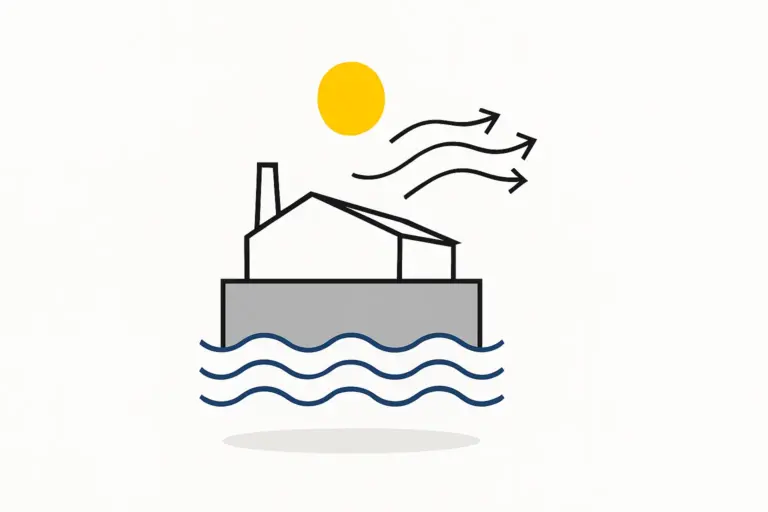

An entrepreneur invests millions to establish a state-of-the-art solar module factory. The facility is ready, the staff is trained, and the first production run is scheduled. But on the first day of operation, a city-wide power outage halts the entire production line.

Mid-cycle, the laminator cools down with valuable materials still inside, creating significant waste. This scenario is a reality for industrial ventures in regions with developing or isolated power infrastructure.

For any manufacturing business, a stable power supply isn’t a luxury—it’s the foundation of operational continuity and profitability. Below, we explore the unique energy challenges facing manufacturing plants, particularly in island or weak grid environments, and outline a strategic approach to securing an uninterrupted power supply.

The Global Challenge of Grid Instability

As economies grow, so does their appetite for electricity. The International Energy Agency (IEA) reported in 2022 that global electricity demand is steadily rising, with an expected annual growth of 2.7% through 2025, driven largely by emerging and developing economies. But grid infrastructure in these regions often struggles to keep pace, leading to frequent power disruptions.

For businesses, the consequences are severe. The World Bank notes that in Sub-Saharan Africa, where electricity access is the lowest globally, businesses with a connection still face an average of 9.6 power outages per month. These interruptions are more than minor inconveniences; they translate into lost production hours, damaged equipment, and significant financial losses, costing businesses hundreds of billions of dollars globally each year.

This challenge is particularly acute for ‘island grids’—power systems that are not connected to a larger continental grid. These can be found on actual islands or in remote mainland areas. Such isolated systems are often defined by:

- Voltage and Frequency Fluctuations: Unstable power that can damage sensitive electronics in modern machinery.

- Frequent Blackouts: Complete interruptions in power supply that can last for minutes or hours.

- Dependence on Imported Fuels: Many island grids rely on diesel generators, making electricity costs volatile and high, often exceeding $0.30 per kilowatt-hour (kWh), according to the International Renewable Energy Agency (IRENA).

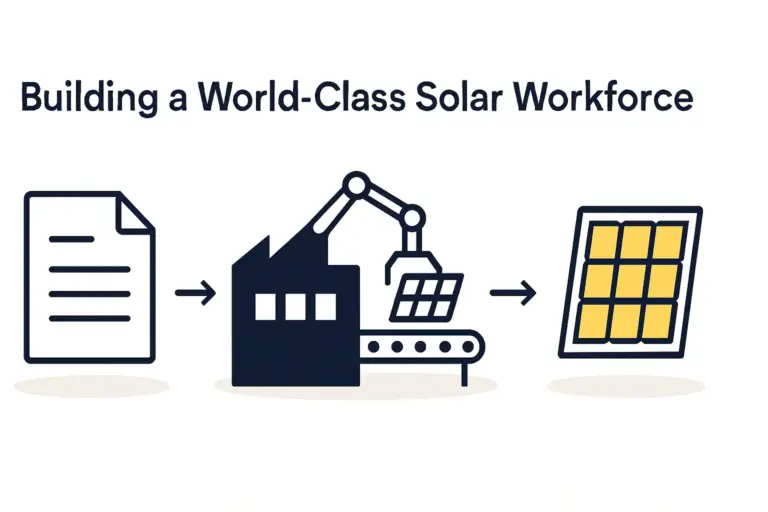

Why Solar Manufacturing is Uniquely Vulnerable

A solar module factory operates with highly specialized, energy-intensive equipment. Machines like automated cell stringers and laminators require a continuous and stable supply of electricity to function correctly.

A sudden power loss during a lamination cycle, for example, can ruin an entire batch of modules—a costly error. Similarly, abrupt shutdowns can cause mechanical stress or electronic failure in precision machinery, leading to expensive repairs and extended downtime. The success of a modern factory, therefore, is directly tied to the quality of its power supply.

Evaluating Power Backup Solutions

Faced with an unreliable grid, business owners traditionally turn to diesel generators as a backup solution. While functional, this approach comes with significant drawbacks that affect both the bottom line and operational efficiency.

The Drawbacks of Diesel Generators

- High and Volatile Fuel Costs: The price of diesel is subject to global market fluctuations and local supply chain challenges, making operational expenditures difficult to predict and control.

- Maintenance Demands: Generators require regular, skilled maintenance, adding to fixed costs.

- Environmental and Logistical Concerns: Noise, emissions, and the logistics of fuel storage and delivery create additional operational hurdles.

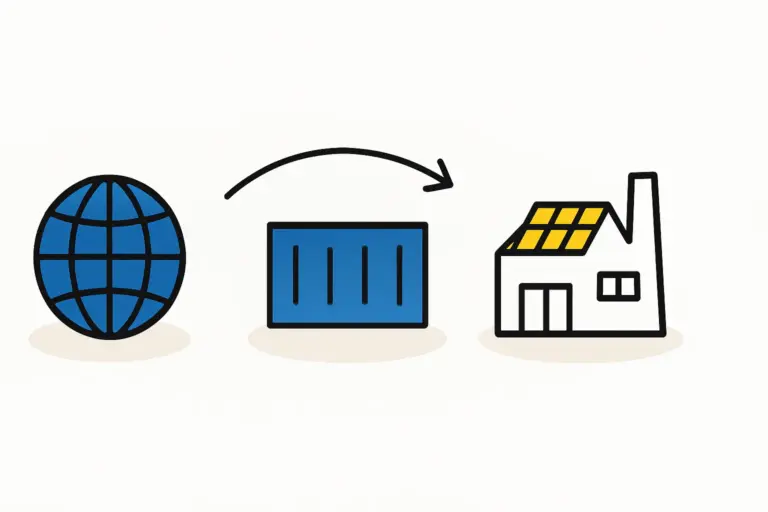

The Strategic Alternative: Solar-Plus-Storage

A more modern and economically sound solution is an integrated solar-plus-storage system. This approach combines a solar photovoltaic (PV) array with a Battery Energy Storage System (BESS) to create an independent, reliable power source for the factory.

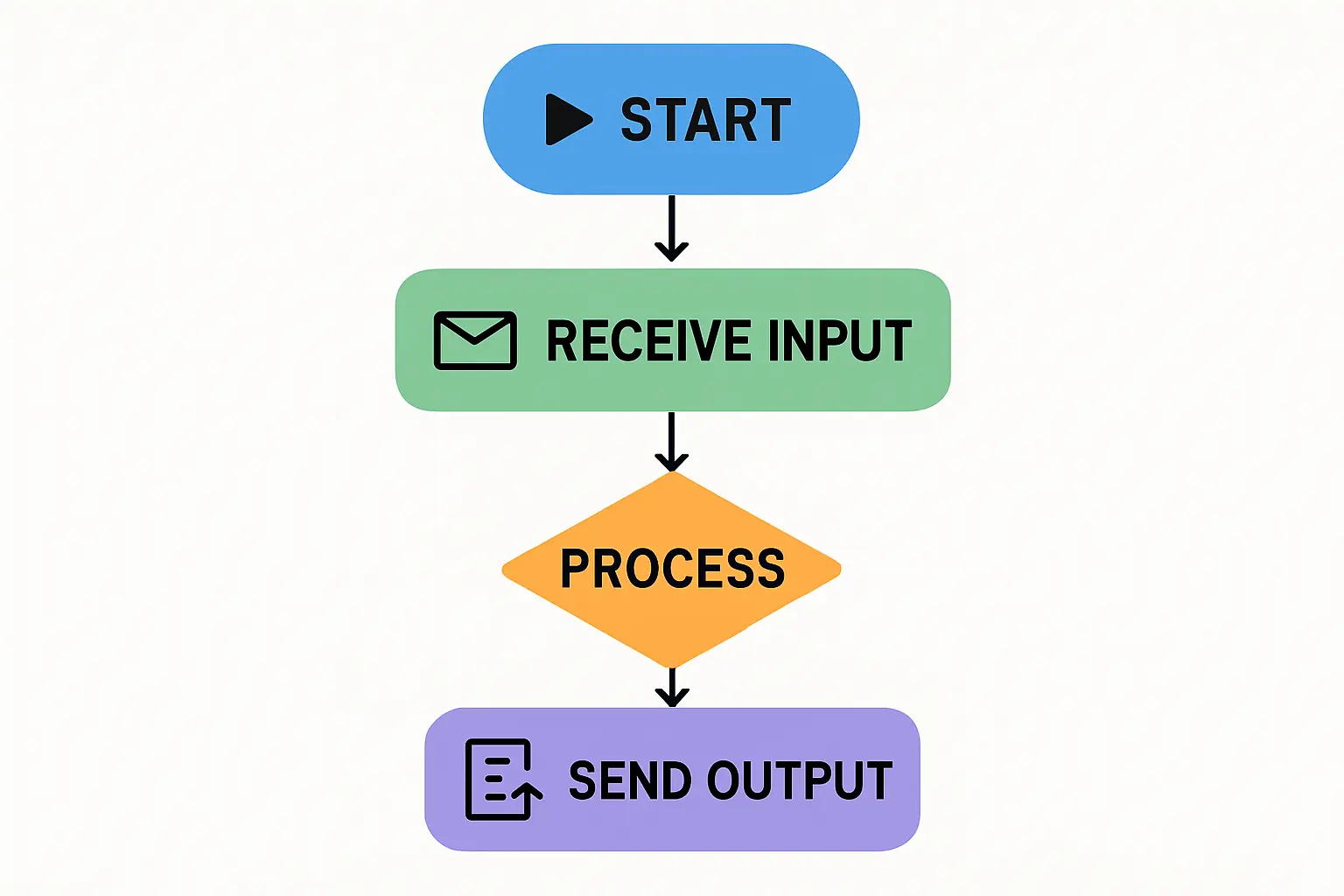

The system functions in four stages:

- Generation: The solar PV array, often installed on the factory roof, generates clean electricity during daylight hours.

- Consumption: This electricity directly powers the factory’s operations, reducing reliance on the grid.

- Storage: Excess energy generated is used to charge the BESS.

- Backup and Stability: During a grid outage, the BESS instantly provides uninterrupted power to critical machinery. It can also stabilize the power supply by smoothing out voltage sags or surges from the grid.

Experience from J.v.G. turnkey projects shows how this integrated system can transform a factory’s energy profile. For instance, a 25 MW solar module factory established in a Caribbean island nation faced daily grid fluctuations that threatened production. By implementing a 1.5 MW solar PV system with a 2 MWh battery storage system, the facility achieved remarkable results:

- Downtime reduced by over 90%.

- Annual electricity costs cut by 40%.

- Return on investment (ROI) projected in under five years.

This real-world example demonstrates that a solar-plus-storage system is not just an emergency backup; it’s a strategic investment in operational resilience and long-term cost control.

Key Planning Considerations

Implementing such a system successfully requires careful planning. Entrepreneurs considering a solar manufacturing plant in a region with grid challenges should factor this need in from the very beginning.

Key considerations include:

- Load Analysis: A thorough analysis of the factory’s energy consumption is essential to correctly size the PV array and BESS. The goal is to match generation and storage capacity to the power demands of critical machinery.

- System Integration: Professional integration with the factory’s electrical infrastructure is crucial to ensure seamless switching between grid power and battery power.

- Quality of Components: The long-term reliability of the system depends on the quality of the solar panels, inverters, and battery technology used.

Frequently Asked Questions (FAQ)

Is a solar-plus-storage system mandatory for a new factory?

While not technically mandatory, it’s a highly strategic investment for any manufacturing operation in a location with an unreliable or expensive grid. It mitigates major financial and operational risks.

What is the typical payback period for such an investment?

The payback period varies depending on local electricity rates, the cost of diesel, and the amount of solar irradiation. However, as demonstrated in past J.v.G. projects, payback periods of three to seven years are increasingly common, making it a financially compelling decision.

Can this system power the entire factory?

Systems can be designed for different scenarios. Some businesses choose to provide backup only for their most critical production machinery, while others size the system to power the entire facility during an outage. A phased approach, starting with critical loads, is often practical.

How does this affect the factory’s building requirements?

The main physical requirements are roof or ground space for the solar PV array and a secure, climate-controlled area for the battery energy storage system. These considerations should be incorporated into the initial facility design.

Conclusion: Securing Your Investment with Energy Independence

For an entrepreneur entering the solar manufacturing industry, ensuring a stable power supply is as crucial as sourcing the right machinery. In regions where grid infrastructure is a known challenge, relying solely on the public utility is a significant business risk.

An integrated solar-plus-storage system offers a clear path toward energy independence. It insulates the operation from grid instability, protects valuable equipment, and turns a volatile operational cost into a predictable, long-term investment. By taking control of its energy supply, a business positions itself for sustained growth and profitability, no matter the condition of the local grid.