An entrepreneur looking at a map of his region—a long coastline dotted with ports, resorts, and growing cities—sees immense potential for solar energy. Yet he also sees a recurring problem: standard solar modules installed near the sea often show rapid decay, with corroded frames and declining performance after just a few years. This common scenario highlights a significant market opportunity: producing solar modules engineered to withstand the harsh conditions of marine and high-humidity climates.

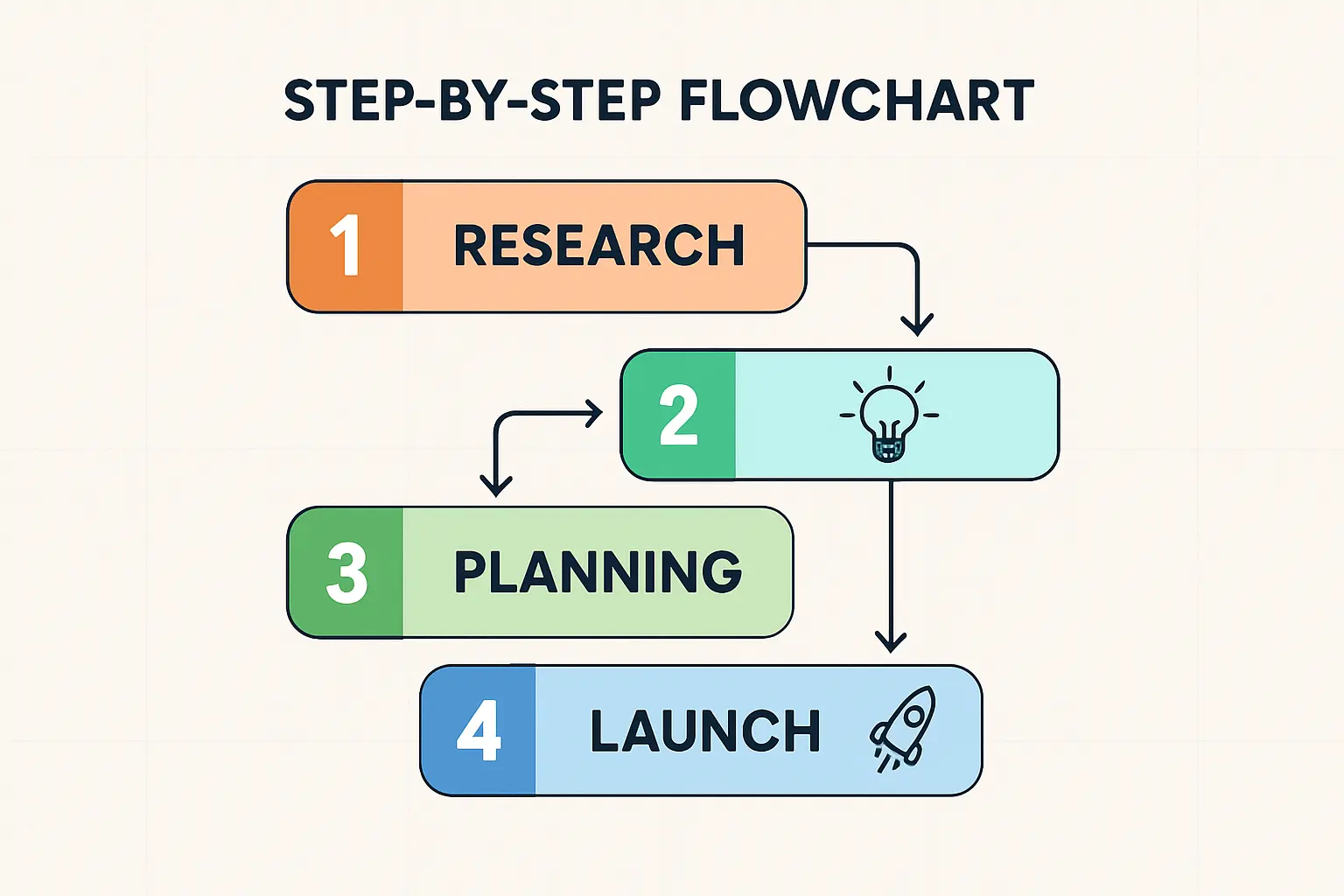

Successfully manufacturing for this niche isn’t about reinventing the entire production process, but about strategically modifying materials and quality control. This article outlines the key adjustments to the Bill of Materials (BOM) and production process required to build durable, salt-mist resistant solar modules, transforming a technical challenge into a competitive advantage.

Understanding the Challenge: Why Standard Modules Fail in Coastal Regions

Coastal and tropical environments present a dual threat to solar modules: high humidity and aerosolized salt, commonly known as salt mist. When this corrosive combination penetrates a module, it triggers a cascade of failures that can severely shorten the asset’s productive life.

The primary mechanisms of degradation include:

-

Galvanic Corrosion: When two different metals, such as the aluminum frame and steel mounting hardware, are in contact with an electrolyte like saltwater, an electrochemical cell forms, causing the more reactive metal to corrode at an accelerated rate.

-

Pitting and Crevice Corrosion: Saltwater can become trapped in small gaps, such as under the junction box or between the frame and the glass. In these oxygen-deprived crevices, the chloride ions in the salt aggressively attack protective coatings and the base metal, leading to deep, localized pits that weaken the module’s structure.

To standardize product resilience, the industry relies on certifications like the IEC 61701 Salt Mist Corrosion Test. This test exposes modules to a concentrated salt spray in a controlled chamber to simulate years of coastal exposure. Achieving a high severity level (e.g., Severity 6) in this test independently verifies that a module is fit for marine environments.

A Strategic Bill of Materials (BOM) for Corrosive Environments

The foundation of a salt-mist resistant module lies in its components. A manufacturer must carefully select materials that offer superior protection against moisture and corrosion. For those new to the industry, a solar module bill of materials (BOM) is essentially the master list of every component required for production.

The Frame: The Module’s First Line of Defense

The aluminum frame provides structural support and is the component most visibly affected by corrosion. A standard anodized frame, while sufficient for many inland climates, often lacks the resilience for sustained salt spray exposure.

The primary vulnerability is the thickness of the protective anodized layer. Once breached, corrosion can quickly set in. Strategic upgrades include:

-

Increased Anodization Thickness: Specifying an anodization layer of at least 20 micrometers (μm), compared to the standard 10–15 μm, provides a more robust barrier.

-

Powder Coating: Applying a durable powder coating over the aluminum frame offers excellent chemical and corrosion resistance.

-

Fiber-Reinforced Polymer (FRP) Frames: For the most extreme environments, replacing the aluminum frame entirely with a non-corrosive composite like FRP eliminates the risk of metallic corrosion altogether.

While these options add a small percentage to the material cost, they can extend the module’s effective lifespan by years, significantly improving the business case for projects in coastal locations.

Encapsulant and Backsheet: Protecting the Cells from Within

The solar cells themselves are protected from the environment by layers of encapsulant and a protective backsheet. The ability of these layers to block moisture is measured by their Water Vapor Transmission Rate (WVTR)—the lower, the better.

Standard modules typically use EVA (Ethylene Vinyl Acetate) as an encapsulant. While cost-effective, EVA has a relatively high WVTR. A superior alternative for humid environments is POE (Polyolefin Elastomer). POE offers a much lower WVTR, providing better long-term protection against moisture ingress that can lead to delamination or internal corrosion of cell contacts.

Similarly, the backsheet must act as an impermeable barrier. While many multi-layer polymer backsheets exist, the ultimate solution for moisture protection is found in glass-glass modules. By replacing the polymer backsheet with a second pane of glass, the cells are hermetically sealed, offering the highest possible resistance to humidity and salt mist.

Sealing and Adhesion: Eliminating Points of Entry

Every seam and connection point on a module is a potential pathway for moisture. The choice of sealants and adhesives is therefore critical.

-

Junction Box: The junction box must have a high ingress protection rating (IP67 or IP68) and be attached with a durable, waterproof adhesive. High-grade silicone is often preferred over double-sided tapes for a more permanent and robust seal.

-

Edge Sealing: The perimeter of the laminate (the glass-encapsulant-backsheet sandwich) is a critical area. Applying a butyl or silicone edge sealant before framing creates a final barrier that prevents moisture from wicking into the module layers over time.

Adapting the Production Process for Maximum Durability

Specifying the right materials is only half the battle. The assembly process must be executed with precision to ensure these components perform as intended. A review of the standard solar panel manufacturing process highlights key stages where adjustments are necessary.

Precision in Lamination and Framing

The lamination stage, where the module layers are fused together under heat and vacuum, is a pivotal step. Any trapped air bubbles or incomplete adhesion can create voids that later become collection points for moisture. Lamination cycles—including temperature, pressure, and duration—must be optimized for the chosen encapsulant (e.g., POE often requires different parameters than EVA).

Automated framing machines ensure the frame is applied with consistent pressure and the sealant is distributed evenly, creating a uniform, weather-tight seal that is difficult to achieve with manual processes.

Implementing a Rigorous Quality Control (QC) Regimen

High-performance modules demand a more stringent quality control regimen than standard products. Key QC checkpoints are essential to verify durability.

Essential tests include:

-

Electroluminescence (EL) Testing: Performed both before and after lamination, EL testing reveals microcracks and other cell defects invisible to the naked eye. These cracks can be exacerbated by mechanical stresses and become pathways for corrosion.

-

Adhesion Peel Tests: Periodically testing the adhesion strength of the encapsulant, backsheet, and junction box adhesive verifies the effectiveness of the lamination and curing processes.

-

Wet Leakage Current Test: This safety and quality test measures the module’s insulation against moisture, ensuring there are no unintended electrical paths that could cause power loss or safety hazards.

A well-configured turnkey solar module manufacturing line designed by an experienced partner will integrate these critical QC stations directly into the production flow, ensuring consistent quality without creating bottlenecks.

The Business Case: Turning a Technical Challenge into a Market Advantage

Manufacturing modules for corrosive environments is a strategic move that can yield significant business benefits.

-

Premium Product Offering: Modules certified for salt-mist and high-humidity resistance can command higher prices and deliver better profit margins.

-

Reduced Warranty Risk: Building a more durable product from the outset leads to fewer warranty claims, reducing long-term financial liabilities and protecting the company’s reputation.

-

Access to Underserved Markets: This specialization opens doors to lucrative segments such as coastal real estate developments, ports, island nations, offshore installations, and even agricultural facilities (where ammonia corrosion presents a similar challenge).

This approach is particularly relevant for entrepreneurs in the Middle East, Southeast Asia, and coastal Africa—regions where high solar irradiation and corrosive atmospheric conditions frequently coexist. By producing a product tailored to local needs, a new manufacturer can effectively compete against generic, low-cost imports.

Frequently Asked Questions (FAQ)

Q1: What is the IEC 61701 certification?

IEC 61701 is the international standard for testing the resistance of solar modules to salt mist corrosion. It involves placing modules in a chamber and subjecting them to a defined salt spray for a set period. The standard includes multiple severity levels, with Level 6 being a common benchmark for modules intended for marine or coastal deployment.

Q2: Do these modifications significantly increase production cost?

The increase in the Bill of Materials cost is typically modest, often in the range of 5–10%. This additional investment is generally offset by the module’s higher selling price, increased bankability for projects, and substantially lower risk of future warranty expenses.

Q3: Can an existing production line be upgraded to produce these modules?

Yes, an existing line can be adapted. The main adjustments involve qualifying new materials in the BOM, reprogramming the lamination and framing machine parameters, and enhancing the quality control procedures. It does not necessarily require a complete change of core machinery.

Q4: Is POE always a better encapsulant than EVA?

For applications requiring high moisture resistance and protection against Potential-Induced Degradation (PID), POE is technically superior. However, EVA remains a cost-effective and reliable choice for many standard applications. The selection depends on the target market and the desired product positioning.

Next Steps in Your Project Planning

Manufacturing specialized solar modules for marine environments is a calculated strategy that aligns product engineering with a clear market need. The process hinges on a deliberate combination of superior materials, precisely controlled production processes, and an uncompromising approach to quality control.

Understanding these technical requirements is the first step. The next is to translate this knowledge into a coherent business plan, financial model, and factory layout. Structured educational resources, such as the e-courses provided by pvknowhow.com, are designed to guide entrepreneurs without a technical background through each stage of this detailed planning process, from initial concept to a fully operational facility.