Disclaimer: This case study represents a composite example derived from real-world

consulting work by J.v.G. Technology GmbH in solar module production and factory optimization. All data points are realistic but simplified for clarity and educational purposes.

Many successful entrepreneurs considering entry into the solar industry often overlook a powerful asset they may already possess: an existing, underutilized industrial building. The common assumption is that starting a solar module factory requires constructing a new facility from the ground up.

However, a more capital-efficient and faster path often lies in retrofitting an existing plant—a strategy known as a ‘brownfield’ conversion. This strategy offers a compelling business case, particularly in regions like Mexico, where nearshoring and access to the North American market are creating significant opportunities. This article explores the strategic, financial, and operational aspects of converting an existing factory into a modern solar module production line, using a realistic investment scenario as a guide.

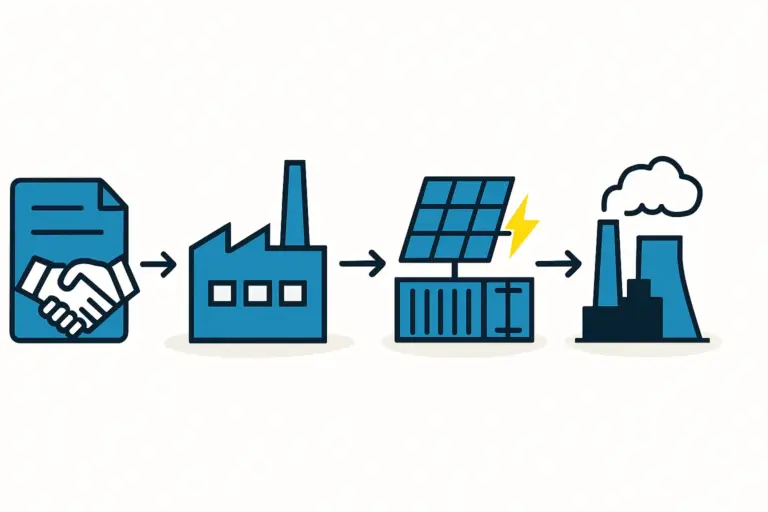

The Strategic Choice: Brownfield vs. Greenfield Projects

Before any investment is made, investors face a fundamental decision: build a new facility or adapt an existing one. Understanding this distinction is crucial for shaping the project’s entire scope, timeline, and budget.

Greenfield Project:

This involves acquiring land and constructing a brand-new factory designed specifically for solar module manufacturing. It offers complete design freedom but typically requires higher initial capital and a longer timeline due to construction and permitting.

Brownfield Project:

This involves purchasing or repurposing an existing industrial facility. While it imposes certain design constraints based on the building’s structure, it can significantly reduce initial investment and accelerate time-to-market.

For many investors, especially those entering the market for the first time, the brownfield approach offers a more pragmatic and financially accessible route.

A Case Study: Retrofitting a Manufacturing Plant in Mexico

To illustrate the process, consider a common scenario that European turnkey engineering team handles. An investor in Mexico has access to a 5,000 m² industrial building previously used for another type of manufacturing. The objective is to convert this space into a 100 MW annual capacity solar module production facility.

The strategic location in Mexico provides logistical advantages for serving both the domestic market and, crucially, the United States, benefiting from favorable trade agreements. The project goal is not merely to install machines but to engineer a high-efficiency production environment within an existing structure.

The Brownfield Advantage: Key Benefits for Investors

Converting an existing facility offers several compelling business advantages that directly impact the project’s return on investment.

Lower Initial Investment

The most immediate benefit is a significant reduction in capital expenditure. By eliminating the costs of land acquisition and new construction, investors can lower their initial outlay by as much as 20-40% compared to a comparable greenfield project. These funds can then be reallocated to higher-quality production machinery or working capital.

Accelerated Time-to-Market

In a rapidly evolving market, speed is a competitive advantage. A brownfield project can be operational in as little as 8–10 months, while a greenfield project often takes 12–18 months or more due to lengthy construction, permitting, and utility connection phases. This faster timeline means revenue generation begins sooner.

Leveraging Existing Infrastructure

Established industrial buildings are typically located in areas with ready access to essential infrastructure. This often includes high-capacity electrical grids, water and gas lines, road and logistics networks, and an available local workforce—elements that can be costly and time-consuming to develop for a new site.

Critical Challenges in a Brownfield Conversion

While advantageous, a brownfield project is a complex engineering challenge requiring meticulous planning and technical expertise. Simply placing machinery into an old building is a formula for inefficiency and operational failure.

Structural Assessment and Redesign

The first step is a thorough technical audit of the facility. Key considerations include:

-

Floor Load Capacity: Automated production lines, especially heavy machinery like laminators, exert significant point loads. The concrete slab must be assessed and potentially reinforced.

-

Ceiling Height: Sufficient vertical clearance is essential for robotic arms, overhead gantries, and maintenance access.

-

Column Spacing: The placement of support columns dictates the production line’s layout and material flow. The layout must be engineered around these fixed constraints.

A detailed review of the building requirements for a solar factory is essential for any conversion project.

Utility and Climate Control Upgrades

Solar module production requires a controlled environment, and existing HVAC systems are rarely adequate. A significant portion of the retrofit involves designing and installing systems to maintain cleanroom conditions, precise temperature, and humidity levels, particularly in the lamination and cell handling areas. The electrical system also requires substantial upgrades to reliably power the energy-intensive machinery.

Optimizing the Production Layout

The core engineering task is to design an efficient production line within the building’s existing footprint. This involves mapping the entire solar panel manufacturing process—from incoming raw materials to final module packaging—and optimizing the flow to minimize material handling and prevent bottlenecks. This often requires creative solutions to work around structural columns or irregular floor plans.

The Turnkey Partner’s Role in a Successful Conversion

Navigating these challenges requires specialized knowledge that bridges civil engineering, process engineering, and solar technology. This is where a turnkey solutions provider becomes invaluable. Experience from numerous European EPC projects shows that an effective partner manages the entire conversion process, including:

-

Technical Feasibility Study: Conducting an on-site audit to determine if the building is a suitable candidate for conversion.

-

Layout and Process Engineering: Designing the optimal production flow and machinery placement to maximize efficiency within the building’s constraints.

-

Equipment Specification and Integration: Selecting the right solar manufacturing equipment that fits the physical space and production goals.

-

Project Management: Overseeing all aspects of the retrofit, from structural modifications and utility upgrades to machinery installation and commissioning.

This integrated approach aligns all technical variables, transforming a potential liability into a productive asset.

Investment Overview: A Brownfield Project Scenario

For a 100 MW solar module factory in a repurposed 5,000 m² building, a typical investment breakdown might look like this. These figures are illustrative and serve as a general guide.

-

Building Retrofit & Upgrades (HVAC, Electrical, Structural): $1.0 million – $1.5 million

-

Production Equipment (100 MW Automated Line): $4.0 million – $5.5 million

-

Installation, Commissioning & Training: $0.5 million

-

Total Estimated Investment: $5.5 million – $7.5 million

Compared to a greenfield project, which could easily exceed $10 million when land and construction costs are included, the financial efficiency of the brownfield approach is clear.

Frequently Asked Questions (FAQ)

What is the ideal ceiling height for a solar factory conversion?

A minimum clear height of 6 to 8 meters is generally recommended to accommodate modern automated equipment, maintenance access, and ventilation systems. Lower ceilings can limit the choice of machinery and complicate the layout.

Can any industrial building be converted?

No. A thorough assessment is critical. Buildings with low floor load capacities, closely spaced support columns, or an insufficient power supply may be unsuitable or require cost-prohibitive modifications.

How many employees are needed for a 100 MW factory?

For a semi-automated 100 MW line operating in three shifts, a staff of approximately 50 to 70 people is typical. This includes production operators, technicians, quality control personnel, and administrative staff.

What are the main differences in cost between a brownfield and greenfield project?

The primary cost saving in a brownfield project comes from avoiding land purchase and new building construction. However, retrofitting costs for HVAC, electrical, and structural upgrades can be substantial. A greenfield project has higher initial construction costs but offers complete design freedom, which can lead to higher long-term operational efficiency.

Conclusion: The Path from Existing Plant to Future-Ready Factory

A brownfield conversion is a strategic, agile, and capital-efficient pathway into the solar module manufacturing industry. It allows investors to leverage existing assets, shorten project timelines, and deploy capital more effectively. However, its success is not guaranteed. It hinges on rigorous upfront technical assessment and expert engineering to overcome the inherent constraints of the existing structure.

With the right planning and partnership, an empty factory is not a liability but an opportunity—a foundation upon which a competitive and profitable solar manufacturing business can be built.

Download the Brownfield Solar Conversion Case Study (PDF)

Author: This case study was prepared by the

turnkey solar module production specialists at J.V.G. Technology GmbH

It is based on real data and consulting experience from J.v.G. projects

worldwide, including installations ranging from 20 MW to 500 MW capacity.