Moldova’s formal recognition as an EU candidate country in June 2022 was more than a political milestone; it marked a profound economic shift. For the country’s entrepreneurs and business leaders, this opened a direct pathway to the European Union’s vast single market. In the solar energy sector, this development creates an unprecedented opportunity: to establish a manufacturing base in Moldova to supply one of the world’s most demanding and fastest-growing markets for photovoltaic (PV) modules.

However, accessing this market hinges on meeting its rigorous technical and safety standards. This guide outlines the essential regulatory framework and provides a practical roadmap for a new Moldovan solar factory to achieve the necessary certifications and turn its strategic location into a competitive advantage.

The EU Solar Market: A Demand-Driven Opportunity

The European Union’s commitment to renewable energy, solidified by its REPowerEU strategy, has created immense demand for solar modules. The plan aims to install over 320 GW of solar PV by 2025 and nearly 600 GW by 2030. To reduce its reliance on a single source of imports, the EU has also set a strategic goal to build 30 GW of annual European solar manufacturing capacity by 2025.

This creates a significant opening for new producers on the EU’s periphery. A Moldovan facility is not just another factory; it is a strategic asset that can help the EU diversify its supply chain, offering European buyers greater resilience and stability. For Moldovan entrepreneurs, this translates into clear, sustained demand for locally produced, high-quality solar modules.

Why Moldova Holds a Strategic Advantage

While competing with established global manufacturers may seem daunting, a Moldovan enterprise enjoys several distinct advantages rooted in its geography, trade agreements, and market perception.

Proximity and Logistics

Its location in Europe is a primary asset. A factory in Moldova can significantly reduce shipping times and logistics costs to major EU markets like Romania, Poland, and Germany compared to imports from Asia. This closeness allows for more flexible inventory management and faster responses to market changes—a crucial benefit for European distributors and project developers.

Favorable Trade Environment

The EU-Moldova Association Agreement, which includes a Deep and Comprehensive Free Trade Area (DCFTA), already provides a solid foundation for tariff-free trade. The country’s EU candidate status further strengthens these economic ties, simplifying customs procedures and aligning regulatory expectations over time.

The ‘Made in Europe’ Appeal

European customers are increasingly prioritizing supply chain transparency and regional manufacturing for both geopolitical and ESG (Environmental, Social, and Governance) reasons. Modules produced in an EU candidate country like Moldova can be marketed with a compelling ‘Made in Europe’ narrative, appealing to buyers who value quality, reliability, and shorter, more secure supply lines.

Navigating the Core EU Regulatory Framework

To successfully export solar modules to the EU, a manufacturer must comply with a set of mandatory standards. These are not optional quality labels but legal prerequisites for market access. The process starts with understanding the key certifications.

The Foundation: IEC 61215 & IEC 61730

These two standards from the International Electrotechnical Commission (IEC) form the bedrock of module quality and safety. They are globally recognized and non-negotiable for entry into the EU market.

-

IEC 61215 (Performance): This standard qualifies the design and type approval of crystalline silicon modules. It involves a series of rigorous stress tests—including thermal cycling, damp heat, humidity-freeze, and mechanical load tests—to ensure the module will perform reliably and durably over its expected lifetime.

-

IEC 61730 (Safety): This standard focuses on the module’s safety qualifications. It covers protection against electrical shock, fire hazards, and personal injury, ensuring the module is constructed to be safe for installers, maintenance personnel, and end-users throughout its lifecycle.

The Passport to Europe: CE Marking

The CE mark is a mandatory conformity marking for products sold within the European Economic Area (EEA). By affixing the CE mark, a manufacturer declares that the product meets all applicable EU health, safety, and environmental protection requirements. For solar modules, this declaration is primarily linked to compliance with:

-

The Low Voltage Directive (LVD): Ensures that electrical equipment within certain voltage limits provides a high level of protection.

-

The Electromagnetic Compatibility (EMC) Directive: Ensures the equipment does not generate or is not affected by electromagnetic disturbance.

The CE mark is not a quality certification; it is a declaration of legal compliance.

Environmental Compliance: RoHS and WEEE

Beyond performance and safety, manufacturers must adhere to EU environmental regulations.

-

RoHS (Restriction of Hazardous Substances): This directive restricts the use of specific hazardous materials, such as lead, mercury, and cadmium, in electrical and electronic products.

-

WEEE (Waste Electrical and Electronic Equipment): This directive makes producers responsible for financing the collection and recycling of their products at the end of their life. This typically requires a manufacturer to join a national WEEE producer compliance scheme in each EU country where it sells its modules.

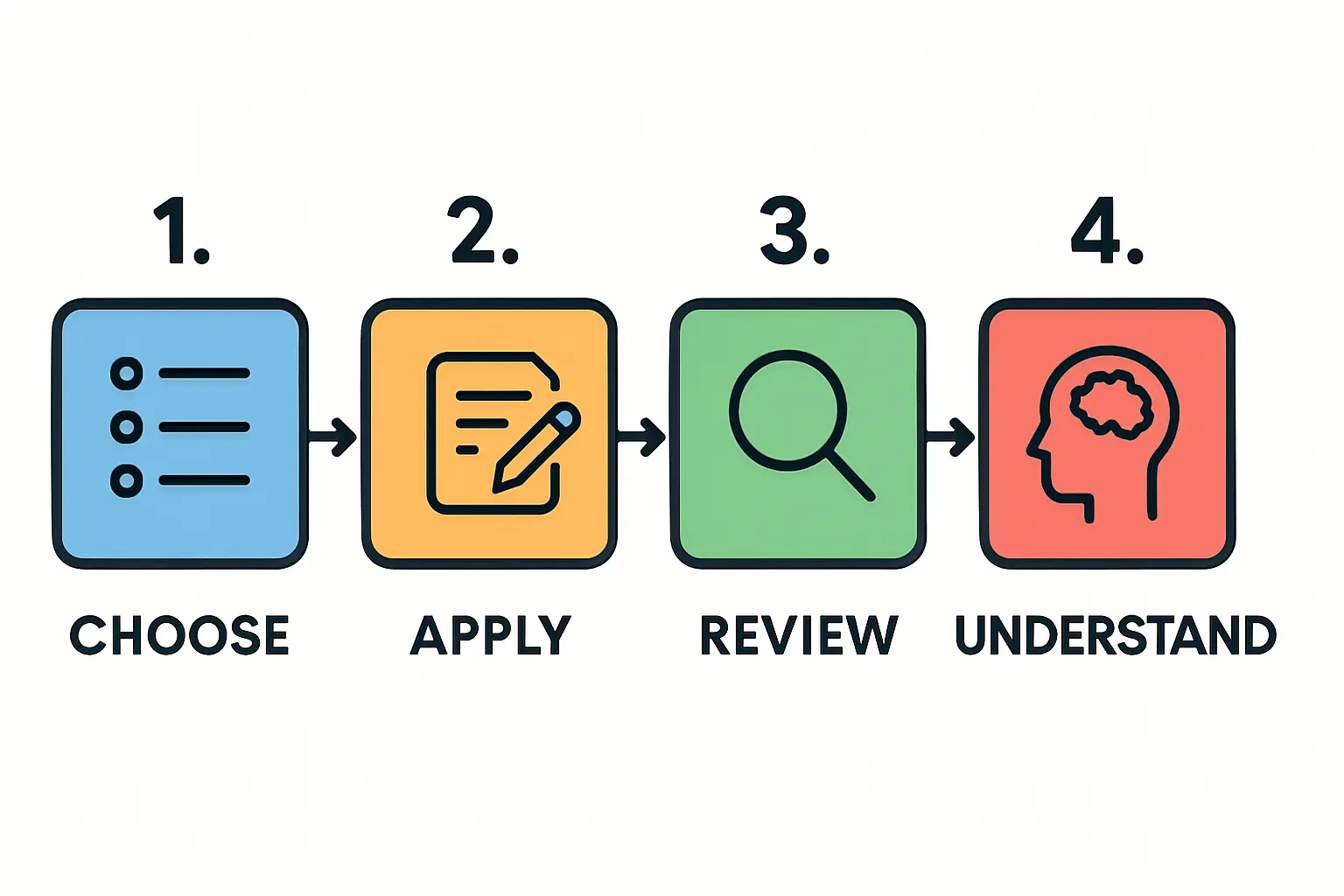

A Practical Pathway to Certification

Achieving these certifications is a systematic process that must be integrated into the factory’s operations from the very beginning. This process should not be an afterthought; it must be a core component of the business plan.

Step 1: Design for Compliance

The journey starts before the first module is produced. The choice of raw materials (the Bill of Materials, or BOM) and the module design must align with certification requirements. Using pre-certified components can streamline the process. This is why selecting the right manufacturing equipment and materials is a critical first decision.

Step 2: Implement a Quality Management System

Consistency is key. A robust quality management system, often certified to ISO 9001 standards, is essential to ensure that every module produced meets the same specifications as the one sent for testing. Accredited labs will perform a factory audit to verify these processes are in place.

Step 3: Pre-Certification Testing

Before committing to the expense of formal testing, conducting in-house tests with equipment like a sun simulator and an electroluminescence (EL) tester helps a manufacturer identify and correct potential issues early.

Step 4: Formal Type Approval with an Accredited Laboratory

The manufacturer submits a set of sample modules to an accredited certification body (e.g., TÜV Rheinland, VDE, Intertek). These labs will perform the full sequence of tests required by IEC 61215 and IEC 61730.

Step 5: Factory Audit and Surveillance

Certification bodies conduct an initial inspection of the manufacturing facility, followed by periodic audits. These audits ensure that the factory continues to operate under the same conditions and with the same materials used for the originally certified modules. Setting up a turnkey solar module production line with an experienced partner ensures these requirements are built into the process from day one.

Step 6: Declaration of Conformity and Marking

Once all tests are passed and audits are completed, the manufacturer receives the final certification reports. At this point, it can legally issue the EU Declaration of Conformity, affix the CE mark to its products, and begin exporting to the European Union.

Common Pitfalls for New Manufacturers

The path to certification is well-defined but presents challenges that can cause significant delays and cost overruns if not anticipated.

-

Underestimating Documentation: The certification process is documentation-heavy. Incomplete or inaccurate records are a common reason for delays.

-

Non-Certified Components: Using a single non-certified material in the Bill of Materials can invalidate the entire certification effort.

-

Ignoring Timelines and Costs: Certification can take 6-12 months from the time modules are submitted and represents a significant expense. The initial investment required for the business must account for these certification costs and timelines.

Experience from J.v.G. turnkey projects shows that planning for certification from the very beginning is the single most important factor in avoiding costly delays and ensuring a smooth market entry.

Frequently Asked Questions (FAQ)

How long does the solar module certification process typically take?

While the laboratory testing itself can take several months, the entire process from initial planning and factory setup to receiving the final certificate can take over a year. It is crucial to build this timeline into the overall business plan.

Are these certifications a one-time event?

No. Certifications require periodic factory surveillance audits (typically annually or semi-annually) to remain valid. Furthermore, if a manufacturer makes any significant changes to the module design or key materials, re-certification may be necessary.

Can a factory in Moldova truly compete with established Asian manufacturers?

Yes. While it may not compete solely on the cost per watt, a Moldovan factory can compete effectively on other critical factors: lower logistical costs, faster delivery times to EU markets, immunity from certain trade tariffs, and the growing customer demand for European-made products with secure supply chains.

Do I need to be a technical expert to manage this process?

A business owner does not need to be a photovoltaic engineer, but they do need a structured approach and reliable technical partners. A well-defined plan, supported by experienced consultants or turnkey providers, can navigate the complexities of certification successfully. Platforms like pvknowhow.com provide structured e-courses to help business professionals with this planning phase.

For Moldovan entrepreneurs, the convergence of the EU’s green energy ambitions and the nation’s new geopolitical standing has created a landmark business opportunity. The path to the European solar market is governed by rigorous standards, but it is clear and manageable. By embedding the principles of quality, safety, and compliance into its foundation, a new Moldovan solar factory can not only meet these requirements but also build a resilient, competitive, and highly valuable manufacturing enterprise for the future.