An investor considering a new solar manufacturing venture in a high-prestige market like Monaco faces a unique challenge. Beyond securing capital and technology, the core proposition must align with the principality’s commitment to sustainability and environmental stewardship. Here, a traditional ‘take-make-dispose’ manufacturing model isn’t just outdated; it’s a direct reputational risk.

The global solar industry is approaching a critical inflection point. While photovoltaic technology is a cornerstone of the green transition, a wave of first-generation panels is nearing the end of its operational life.

Projections from the International Renewable Energy Agency (IRENA) estimate that cumulative solar panel waste could reach 78 million tonnes by 2050. For a forward-thinking entrepreneur, this figure represents not just a looming environmental problem but a significant strategic and economic opportunity.

What is a Circular Economy in Solar Manufacturing?

A traditional, linear manufacturing process extracts raw materials, produces a product, and ends with its disposal. This model is inherently wasteful. By contrast, a circular economy is a systemic approach to economic development designed to benefit businesses, society, and the environment. It is based on three principles: design out waste and pollution, keep products and materials in use, and regenerate natural systems.

In solar manufacturing, this means re-evaluating the entire lifecycle of a photovoltaic module. A standard solar panel is a composite of several valuable materials, typically including:

- Glass: ~75%

- Polymers (EVA, backsheet): ~10%

- Aluminum (frame): ~8%

- Silicon (cells): ~5%

- Copper (interconnects): ~1%

- Trace elements (silver, tin, lead): <0.1%

A circular model seeks to ensure these components do not end up in a landfill. Instead, they are recovered, reprocessed, and reintroduced into the supply chain, creating a closed-loop system that minimizes waste and conserves virgin resources.

The Dual Imperative: Environmental Regulation and Economic Opportunity

The shift towards circularity is driven by two powerful forces: increasing regulatory pressure and a compelling economic case.

Frameworks like the European Union’s Waste Electrical and Electronic Equipment (WEEE) Directive already set high standards. The directive mandates an 85% collection rate and an 80% recycling rate for PV modules, establishing a clear legal precedent for producer responsibility. For businesses operating in or selling to such markets, adherence is non-negotiable.

The economic argument is even more persuasive. The raw materials locked inside end-of-life solar panels hold immense value. IRENA estimates this recoverable value could exceed USD 15 billion by 2050. By establishing processes to reclaim high-value materials like silver and pure silicon, a manufacturer can create a new revenue stream and reduce its long-term dependence on volatile global commodity markets.

Strategic Pillars for a Zero-Waste Solar Factory

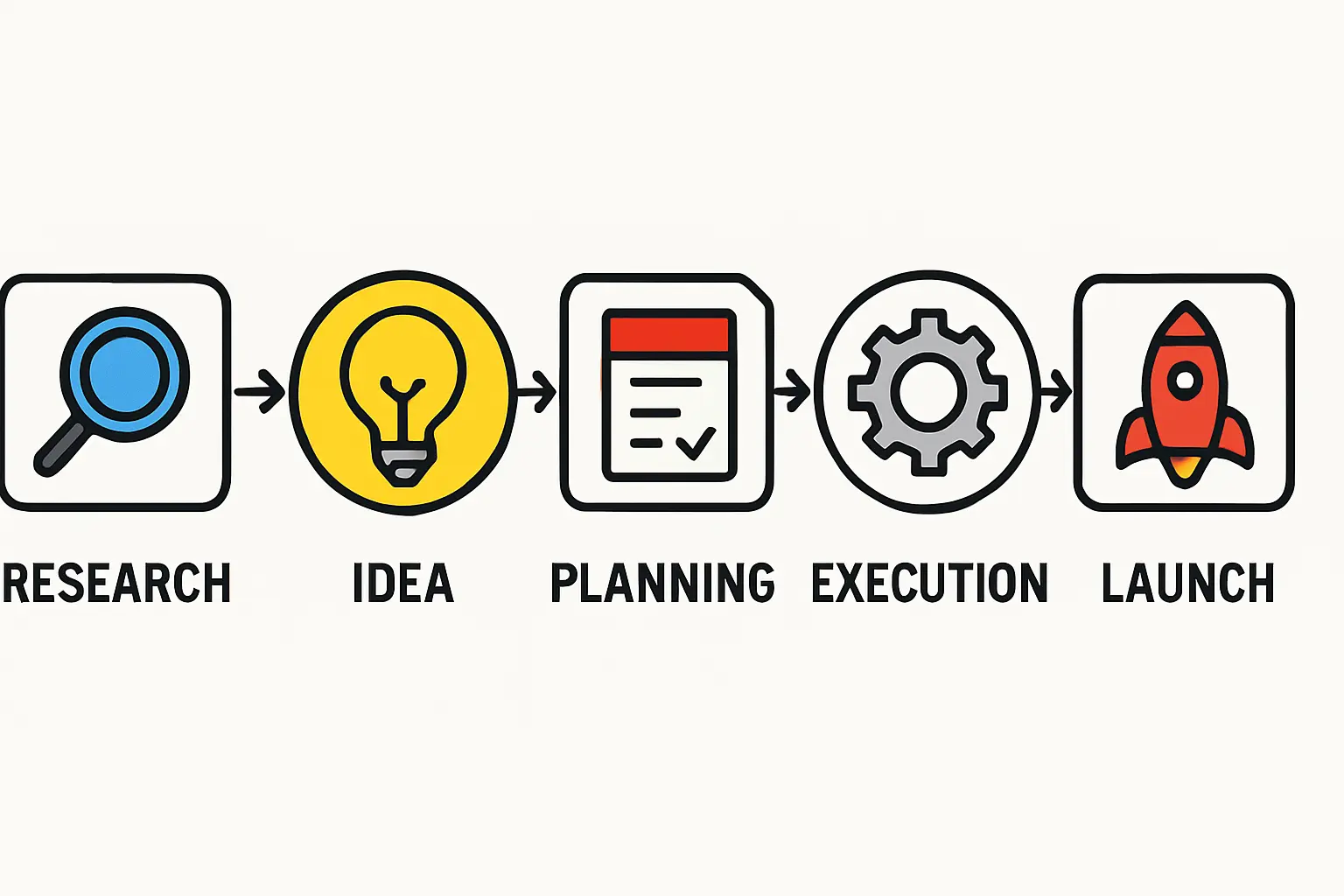

Implementing a circular model is not an afterthought; it must be integrated into the core operational strategy from the initial planning stages. This approach rests on three foundational pillars.

Pillar 1: Designing for Disassembly

The foundation of effective recycling is a product designed to be taken apart. Future-focused manufacturers are exploring module designs that make material separation easier and more cost-effective at the end of life. This involves choices in adhesives, sealants, and frame construction that facilitate automated disassembly, significantly increasing the purity and value of recovered materials. While this is an advanced concept, building it into the initial design of a new solar factory positions an enterprise for future leadership.

Pillar 2: Optimizing Production for Material Efficiency

Waste reduction begins on the factory floor. A meticulously planned solar panel manufacturing process minimizes scrap and material loss at every stage. This includes precise wafer handling to reduce breakage during solar cell production, optimizing ribbon cutting to minimize copper waste, and implementing rigorous solar module quality control to reduce the number of rejected units. Every percentage point of improved material efficiency translates directly to lower production costs and a smaller environmental footprint.

Pillar 3: Establishing a Robust End-of-Life (EoL) Management Program

A credible circular strategy requires a clear, demonstrable plan for managing modules once they are decommissioned. This involves establishing partnerships with specialized recycling firms that employ advanced recovery techniques. Modern thermal and chemical processing methods can now achieve material recovery rates of over 95%, successfully separating glass, silicon, and valuable metals for re-use. Documenting these partnerships and processes is essential for proving a commitment to full lifecycle responsibility.

Case Study: Meeting Principality Standards in Monaco

For an entity operating within Monaco, these principles are not just best practices; they are a license to operate. Monaco’s government and its influential ‘White Paper on Responsible and Sustainable Luxury’ explicitly prioritize circularity, environmental stewardship, and reputational integrity.

A solar manufacturer in this context must demonstrate a ‘zero-waste’ philosophy that aligns with the principality’s brand. A circular model provides a powerful narrative. It frames the venture as a high-technology enterprise that not only produces clean energy but does so with minimal waste, contributing to a sustainable material ecosystem.

This approach transforms a potential industrial operation into a symbol of Monaco’s commitment to a green and prosperous future, satisfying stakeholders from government officials to the investment community. Experience from J.v.G. turnkey projects confirms that integrating these considerations early is far more effective and less costly than attempting to retrofit them later.

Frequently Asked Questions (FAQ)

What is the main challenge in recycling solar panels today?

The primary technical challenge is the delamination process—cleanly separating the layers of glass, encapsulant (EVA), and backsheet without contamination. This is crucial for recovering high-purity materials like silicon and silver, which hold the most economic value.

Is a circular model profitable for a new manufacturer?

While it requires upfront investment in process design and strategic partnerships, a circular model builds long-term value. Profitability comes from reduced raw material costs over time, potential revenue from selling recovered materials, and an enhanced brand reputation, which can lead to preferential market access and a stronger social license to operate.

How does this affect the initial solar factory setup?

It influences the planning process from day one. Equipment selection may favor machines that minimize kerf loss (material lost during cutting) or handle materials more delicately. The factory layout might include designated areas for managing and segregating production scrap for recycling. Most importantly, it embeds a quality-first, waste-minimization culture throughout the entire operation.

Can recycled silicon be used in new solar cell production?

Yes. With advanced purification processes, silicon recovered from end-of-life panels can be refined back to the high-purity levels required for manufacturing new solar cells. This ‘closing of the loop’ is a cornerstone of a truly circular solar economy, reducing the industry’s reliance on energy-intensive virgin polysilicon production.

Conclusion: Building a Future-Proof Solar Enterprise

Implementing a circular economy model is a strategic decision that moves a solar manufacturing business beyond simply producing a green product to creating a green process. For entrepreneurs aiming to operate in jurisdictions with the highest environmental and reputational standards, this approach is no longer optional.

By designing for disassembly, optimizing production, and planning for end-of-life management, a new venture can mitigate regulatory risk, unlock new economic value, and build a resilient, future-proof enterprise. It proves that responsible manufacturing and commercial success are not mutually exclusive; they are inextricably linked.