An entrepreneur looking at Montenegro will see clear potential: a strategic position on the Adriatic, a favorable climate for solar energy, and a clear path toward European Union integration. But transforming this potential into a successful solar module manufacturing operation begins with a foundational, and often underestimated, decision: choosing the right location.

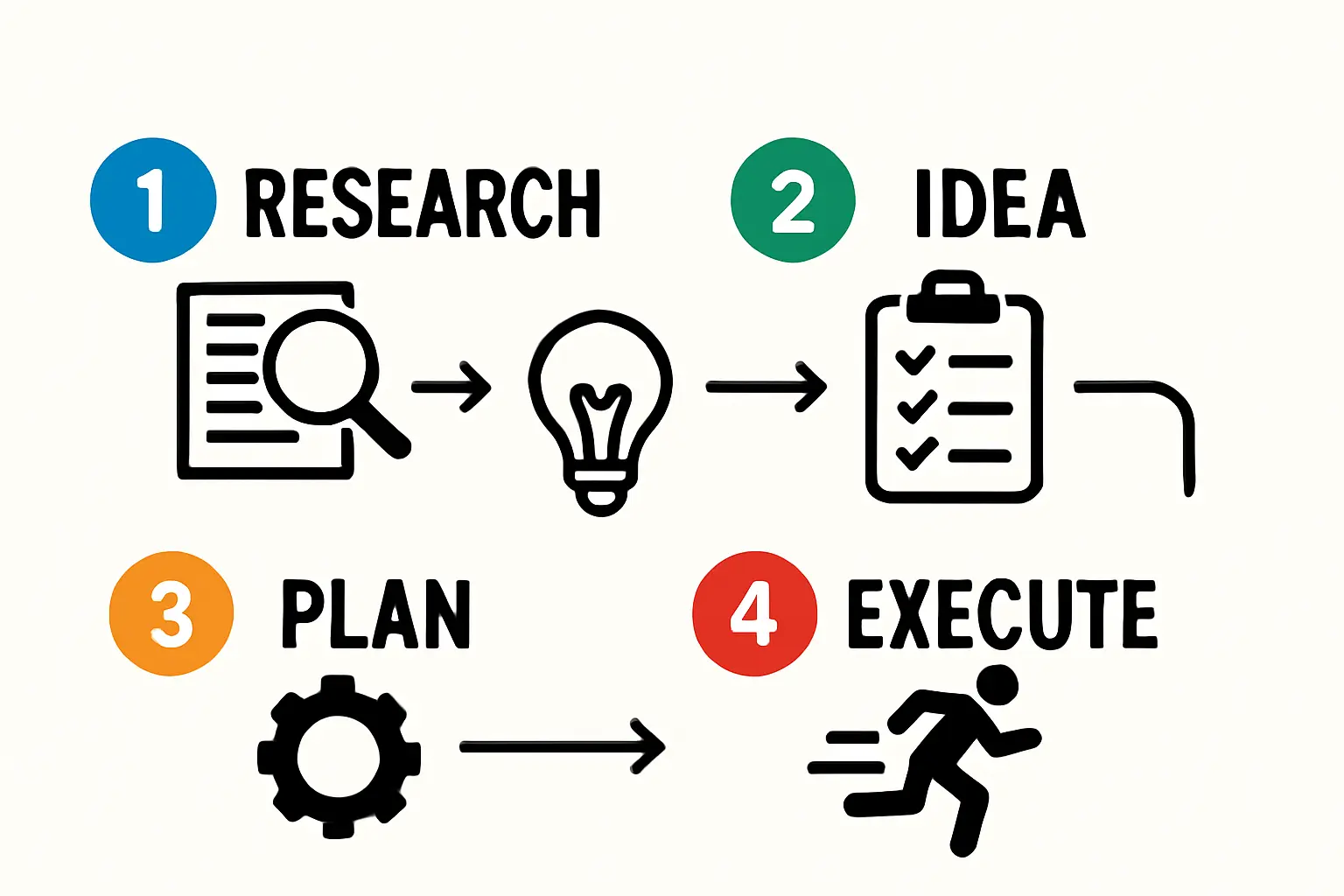

A detailed, strategic evaluation can be the difference between a site that propels growth and one that creates constant operational friction. This guide outlines the critical factors for selecting a factory location in Montenegro, with a specific focus on its designated business and industrial zones. It provides a framework for evaluating sites based on infrastructure, cost, utility access, and logistics—the cornerstones of a resilient manufacturing business.

Why Montenegro? The Strategic Context for Solar Manufacturing

Montenegro offers a unique combination of advantages for investors in the renewable energy sector. As an official EU candidate country, it is steadily aligning its regulations with European standards, creating a stable and predictable business environment. Its low corporate tax rate and various investment incentives, particularly within designated business zones, are designed to attract foreign capital.

The country’s location also offers a logistical gateway, connecting the Adriatic Sea to the Balkan hinterland and wider European markets. For an export-oriented solar module factory, this geographical advantage can significantly reduce transportation costs and delivery times.

Core Criteria for Evaluating Industrial Sites

Choosing a location is not merely a real estate transaction; it is a strategic decision that impacts everything from supply chain efficiency to production uptime.

Infrastructure and Logistics: The Arteries of Your Operation

The physical connections to and from your factory are paramount. A solar module production line relies on a steady inflow of raw materials like glass, cells, and aluminum frames, as well as a seamless outflow of finished products.

Key considerations include:

-

Proximity to Ports and Rail: For importing raw materials and exporting modules, proximity to a major port like the Port of Bar is a significant advantage. The Bar-Belgrade railway line further extends this logistical reach into Central and Eastern Europe.

-

Road Network Quality: Assess the condition and capacity of roads connecting a potential site to major highways. Congestion or poor road quality can lead to delays and increased transportation costs.

-

Supply Chain Access: Consider the distance to potential regional suppliers and, more importantly, the efficiency of customs and import procedures for international shipments.

Utility Access and Reliability: Powering Production

A solar module factory is an energy-intensive operation. Uninterrupted, high-quality power is not a luxury—it is essential for sensitive machinery such as laminators and cell stringers.

-

Electricity Grid: Verify the stability of the local grid. Inquire about the capacity of the nearest substation and the history of power outages. A dedicated high-voltage connection is often necessary.

-

Water and Waste Management: Ensure an adequate supply of industrial-grade water and access to facilities for managing industrial waste in compliance with local environmental regulations.

-

Telecommunications: High-speed internet is critical for modern production management systems (MES), remote diagnostics, and communication.

Utility costs and reliability directly impact operational expenditures and production targets, making these factors a fundamental part of any successful solar panel manufacturing business plan.

Land and Building Considerations: The Foundation of Your Factory

The physical space must accommodate not only the current production line but also future expansion. A typical 50 MW solar module factory requires approximately 5,000 to 7,000 square meters for production and storage.

-

Greenfield vs. Brownfield: A greenfield site (undeveloped land) offers complete design freedom but involves a longer timeline for construction and permitting. A brownfield site (an existing building) can accelerate startup but may require significant retrofitting to meet the specific needs of a solar factory, such as reinforced flooring and clean-room environments.

-

Zoning and Permits: Confirm that the land is zoned for industrial use and understand the full scope of building permits required. Experience from J.v.G. turnkey projects shows that the permitting process can become a significant bottleneck if not managed proactively from the start.

-

Expansion Potential: The ideal site has adjacent land available for future purchase, allowing the facility to scale its capacity without needing to relocate.

Labor Pool and Workforce Availability

A manufacturing facility requires a diverse team—from skilled engineers and technicians to a reliable assembly line workforce—and the local labor market must be able to support these needs.

-

Skilled Labor: Assess the availability of talent with technical or engineering backgrounds. Proximity to cities with technical schools or universities, like Podgorica, is a key advantage.

-

General Labor: Evaluate the size and reliability of the general labor pool in the region. Local wage levels and labor laws will also be a key factor in your operational cost structure.

A Closer Look at Montenegro’s Key Business Zones

Montenegro has established several business zones that offer specific incentives. The choice between them depends on the investor’s primary business model—whether it is export-focused, cost-sensitive, or reliant on a specific labor profile.

The Coastal Advantage: Port of Bar Free Zone

Primarily designed for export-oriented businesses, the Free Zone at the Port of Bar offers streamlined customs procedures and tax exemptions on imported raw materials that are processed and re-exported. For a manufacturer sourcing components globally and selling to European markets, this zone provides unparalleled logistical efficiency.

The Northern Potential: Berane and Mojkovac Zones

Montenegro’s northern region is a focus for government development initiatives. Business zones here, such as in Berane and Mojkovac, often feature significant incentives, including lower land costs, co-financing for job creation, and tax relief. While logistics may be more challenging compared to the coast, the lower operational costs can substantially reduce the overall cost to start a solar panel manufacturing company. This option is compelling for businesses targeting the Balkan domestic market.

The Central Hub: Podgorica and its Vicinity

The area around the capital, Podgorica, offers a balanced profile, providing the best access to a skilled workforce, government institutions, and administrative services. While land and labor costs may be higher than in the north, its central location and proximity to the country’s main airport offer excellent connectivity for both logistics and management.

Frequently Asked Questions (FAQ)

What is the typical size of land needed for a small solar factory?

For a semi-automated production line with a capacity of 20–50 MW per year, a plot of 10,000 to 20,000 square meters is generally recommended. This allows for a 5,000–7,000 square meter building with adequate space for logistics, storage, and future expansion.

Can foreign entities own industrial land in Montenegro?

Yes, foreign individuals and companies can own property and land in Montenegro, subject to the same rights and obligations as domestic entities. This policy is part of the country’s effort to attract foreign direct investment.

How long does the site approval and permitting process usually take?

The timeline can vary significantly depending on the municipality and the complexity of the project. A realistic estimate, from site acquisition to receiving all necessary building permits, can range from 6 to 12 months. Engaging local experts can help navigate local procedures more efficiently.

Are there specific environmental regulations for a solar panel factory?

Yes, like any industrial facility, a solar panel factory must comply with national environmental regulations. This typically involves an Environmental Impact Assessment (EIA) as part of the permitting process, focusing on waste management, water usage, and chemical handling.

Conclusion: A Decision That Defines the Future

Selecting a site for a solar module factory in Montenegro is a multi-faceted decision requiring a careful balance of logistical advantages, operational costs, and the regulatory landscape. The ideal location is rarely the cheapest or the closest to a port; it is the one that best aligns with a company’s long-term strategic goals.

Systematically evaluating each potential site against the core criteria of infrastructure, utilities, land, and labor allows an investor to lay a solid foundation for a successful and scalable manufacturing operation in one of Europe’s most promising emerging markets.