Disclaimer: This case study represents a composite example derived from real-world

consulting work by J.v.G. Technology GmbH in solar module production and factory optimization. All data points are realistic but simplified for clarity and educational purposes.

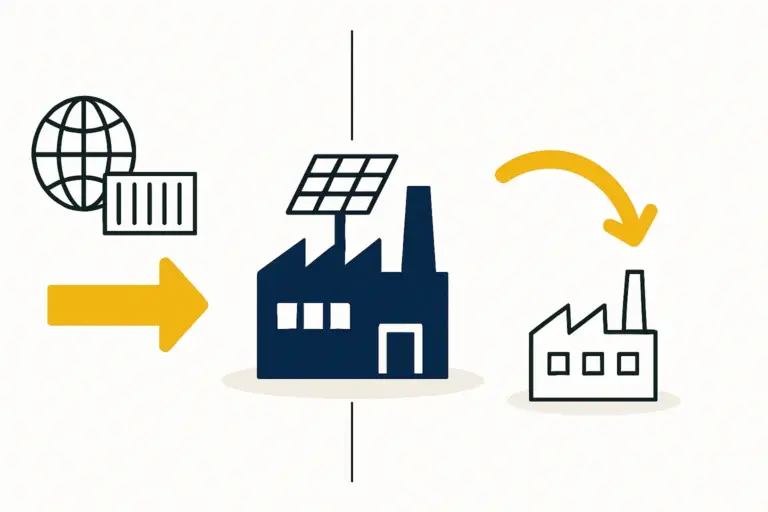

An investor watching Europe’s green transition sees two things clearly: an accelerating demand for solar energy and a critical dependency on imports to meet it. With the vast majority of solar modules powering this transition arriving from thousands of miles away, Europe faces a strategic vulnerability—and entrepreneurs see a significant opportunity to establish manufacturing closer to home.

This article outlines a detailed investment scenario for doing just that: establishing a 100 MW solar module factory within Morocco’s Tanger Med Free Zone. The goal is to produce specialized, high-performance modules for export to the utility-scale solar markets in Spain and France. We’ll explore how leveraging Morocco’s unique geographic, economic, and political advantages can create a highly competitive and profitable manufacturing enterprise.

The Strategic Advantage: Why Morocco?

The viability of this manufacturing model hinges on a powerful convergence of factors that make Morocco an ideal nearshore hub for supplying the European solar market. The fundamental business advantages are clear and compelling.

Geographic Proximity and Logistical Excellence

Located just 14 kilometers from the coast of Spain, the Tanger Med port complex is the largest in the Mediterranean and Africa. Its state-of-the-art infrastructure offers direct, efficient shipping routes to major European ports. For a solar module manufacturer, this means dramatically reduced logistics costs and delivery times compared to competitors in Asia. This proximity enables a more responsive supply chain—a critical factor for large-scale European construction projects.

Favorable Trade and Investment Climate

Morocco’s economic strategy actively encourages foreign investment and export-oriented industries. The Morocco-EU Association Agreement, a comprehensive free trade deal, allows most industrial goods, including solar modules, to enter the European Union market tariff-free. This immediately creates a substantial cost advantage over manufacturers from countries facing EU import duties.

Operating within a designated free zone like Tanger Med offers its own significant financial incentives, including:

- Exemption from corporate tax for the first five years, followed by a capped rate.

- Exemption from value-added tax (VAT) and customs duties.

- Simplified administrative and customs procedures for imports and exports.

This favorable framework is strengthened by Morocco’s national commitment to renewable energy. With a goal of sourcing 52% of its electricity from renewables by 2030 and hosting world-renowned projects like the Noor Ouarzazate solar complex, the country has cultivated a stable, pro-investment environment for the solar industry.

The Product: Engineering for the European Utility Market

Success in a competitive market requires more than a strategic location; it demands a product precisely engineered for the target customer. For the sun-rich regions of Spain and France, this means manufacturing modules that perform optimally under high-temperature and high-irradiation conditions.

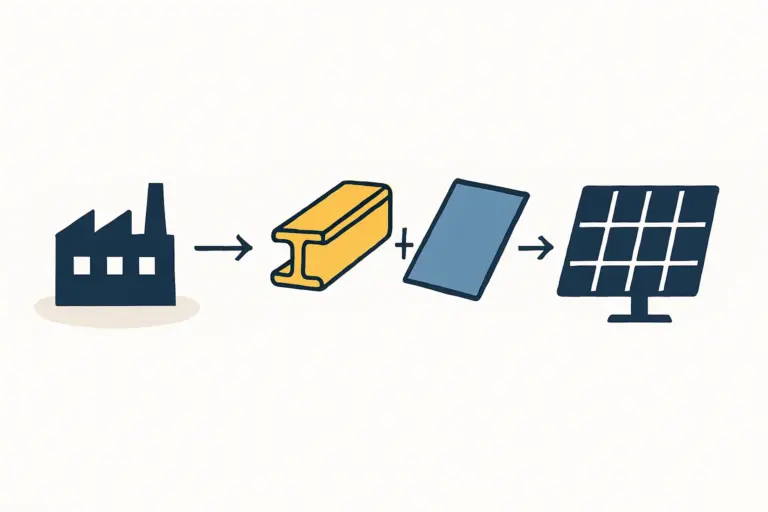

The Case for DESERT+ Technology

Standard solar modules can experience accelerated degradation and reduced efficiency when operating in the intense heat common to Southern Europe’s utility-scale solar farms. Under these conditions, specialized technology creates a key competitive edge.

The plan focuses on producing high-efficiency DESERT+ modules, which are specifically designed for such environments. Key features include:

- High-Efficiency Cells: Utilizing modern cell architectures like TOPCon to maximize energy output per square meter.

- Durable Encapsulation: Employing advanced materials that better resist long-term heat and UV radiation, minimizing power loss over the module’s lifetime.

- Robust Construction: A reinforced frame and specialized glass coatings protect against environmental stressors like sand and high winds.

Producing a technologically superior module tailored to the specific climatic challenges of the target market strengthens the business case and justifies a premium, bankable product.

Aligning Production with Market Demand

A 100 MW annual production capacity is a strategic entry point. It is large enough to achieve economies of scale and supply multiple utility-scale projects per year, yet manageable for a new entrant. This capacity ensures the factory can meet the volume demands of major European energy companies—essential for securing the long-term contracts that underpin the entire investment.

The Operational Framework: A Turnkey Approach

A strategic vision requires a practical execution plan. The path from concept to production involves securing customers, structuring finances, and building the physical plant—a process best managed through a structured, turnkey approach.

Securing Offtake Agreements: The Foundation of Bankability

Before a single piece of equipment is ordered, the primary goal is to secure offtake agreements. These long-term contracts with European utility companies or project developers guarantee the purchase of a significant portion of the factory’s future output. Such agreements are the foundation of the project’s bankability, as they ensure a steady revenue stream and give financiers the certainty they require. The combination of a tariff-free, strategically located factory and a specialized DESERT+ module creates a compelling proposition for potential European buyers.

Financial Planning and Investment Structure

The initial capital expenditure for a 100 MW facility typically falls in the range of USD 25–35 million. A successful investment relies on rigorous financial modeling that accounts for all equipment costs, construction, working capital, and operational expenses. Based on experience from past European PV manufacturers’ projects, a detailed business plan is essential for securing financing. This plan projects revenue based on secured offtake prices and models the return on investment over the project’s lifetime.

The Turnkey Factory Setup

Executing the construction and commissioning of a turnkey solar module factory is a complex, multi-stage process. It involves:

- Facility Design: Laying out the factory floor for optimal material flow and efficiency.

- Equipment Procurement: Sourcing, ordering, and shipping all necessary machinery, from cell stringers to laminators and testers.

- Installation & Commissioning: Assembling the production line and calibrating all equipment to meet quality standards.

- Team Training: Hiring and training local engineers and technicians to operate and maintain the machinery.

Guidance from experienced consultants, such as an established European turnkey engineering team, is invaluable in navigating this process. Their expertise ensures the factory is built to international standards and can begin production on schedule and within budget.

The End Goal: Supplying Europe’s Green Transition

The culmination of this strategic blueprint is a manufacturing facility that directly supplies the engines of Europe’s energy transition: large-scale solar farms. By delivering high-performance, cost-competitive modules from a nearshore location, the Moroccan factory becomes a vital and reliable link in the European solar supply chain. This model not only represents a sound financial investment but also contributes to the energy security and decarbonization goals of the entire region.

Frequently Asked Questions (FAQ)

What is the typical timeline for a 100 MW factory setup?

From the final investment decision to the first certified module coming off the line, a typical timeline is 12 to 18 months. This includes factory preparation, equipment delivery lead times, installation, and commissioning.

Why is a Free Zone like Tanger Med important?

Operating in a free zone provides critical financial and logistical advantages. The primary benefits are tax exemptions, which directly improve profitability, and simplified customs procedures, which reduce administrative burdens and speed up the movement of goods.

Are local skilled workers available in Morocco?

Yes, Morocco has a well-established industrial sector and a growing pool of skilled labor. A core component of any turnkey project is a comprehensive training program to ensure the local team is proficient in operating and maintaining sophisticated production equipment to international quality standards.

How does this model compete with manufacturers from Asia?

This model competes on three main fronts:

- Cost: It eliminates EU import tariffs and significantly reduces shipping expenses.

- Speed: Proximity allows for much faster delivery and a more agile response to market demand.

- Specialization: It focuses on producing a specialized, high-performance module engineered for the specific climatic conditions of its target European market.

Conclusion: From Blueprint to Reality

Establishing a 100 MW solar module factory in Morocco’s Tanger Med Free Zone is a compelling strategic investment. It capitalizes on clear logistical, trade, and economic advantages to serve Europe’s vast and growing demand for solar energy. While the opportunity is significant, its successful realization depends on meticulous planning, robust financial modeling, and expert execution.

For entrepreneurs and investors considering entry into the solar manufacturing sector, a well-structured plan is the first and most critical step. Building the foundational knowledge to evaluate these opportunities is essential. Structured educational resources, like the e-courses from pvknowhow.com, are designed to help you navigate the complexities of creating a successful enterprise in the global solar industry.

Download the 100 MW Morocco Solar Export Case Study (PDF)

Author: This case study was prepared by the

turnkey solar module production specialists at J.V.G. Technology GmbH

It is based on real data and consulting experience from J.v.G. projects

worldwide, including installations ranging from 20 MW to 500 MW capacity.