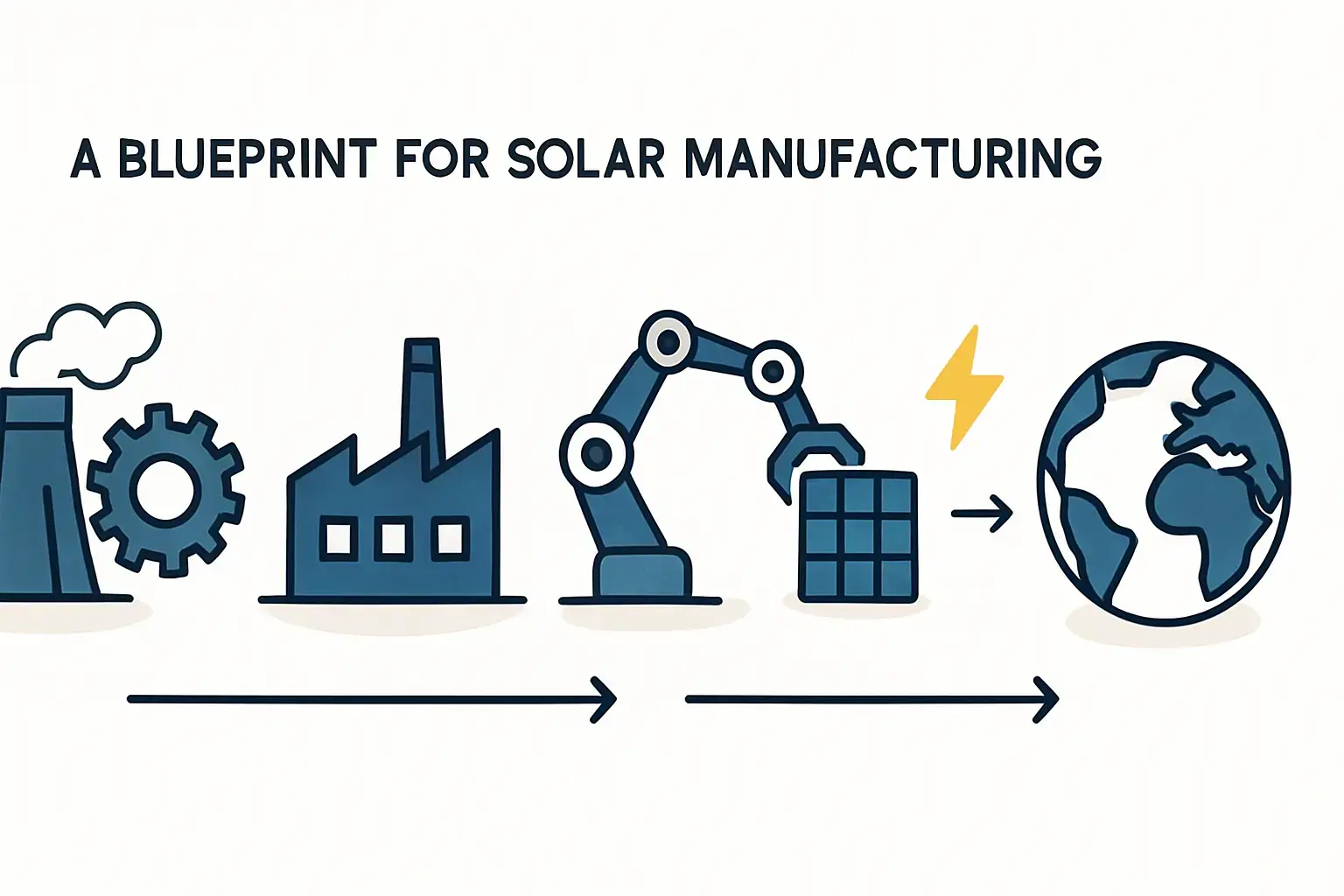

An entrepreneur spots a public tender notification for a multi-megawatt solar energy project in Morocco. His company has extensive experience importing and installing high-quality solar modules. However, his bid is deemed non-compliant, while a competitor with a local assembly operation wins the contract. This scenario is becoming increasingly common as governments worldwide, particularly in Morocco, prioritize local economic development through strategic procurement policies.

For business professionals looking to enter or expand in Morocco’s burgeoning solar market, understanding and meeting Local Content Requirements (LCRs) is more than just a regulatory hurdle—it’s a significant competitive advantage. This article explores how establishing an in-country solar module assembly operation can be the key to unlocking these large-scale public projects.

Understanding Morocco’s Strategic Vision for Renewable Energy

Morocco has positioned itself as a regional leader in renewable energy. The government’s ambitious goal is to increase the share of renewables in its electricity mix to 52% by 2030. This national strategy is driven by key state-affiliated agencies like the Moroccan Agency for Sustainable Energy (MASEN) and the Office National de l’Electricité et de l’Eau Potable (ONEE).

These large-scale energy projects, often financed by international development banks, are not merely about generating clean power. They are designed to achieve broader economic objectives:

- Job Creation: Building a skilled local workforce in a high-growth industry.

- Technology Transfer: Developing domestic technical expertise and industrial capabilities.

- Economic Resilience: Reducing reliance on imported energy technologies and foreign currency expenditure.

To achieve these goals, public tenders for solar projects invariably include Local Content Requirements, mandating that a certain percentage of the project’s value be generated within Morocco.

What Are Local Content Requirements (LCRs) in Public Tenders?

Local Content Requirements are contractual obligations in a public tender that require the winning bidder to use a specified minimum percentage of local goods, services, labor, and supplies. In Moroccan solar tenders, this concept is often called the ‘industrial integration rate.’

This rate is a calculated measure of the value added within the country. A simple statement of intent is not enough; bidders must provide verifiable documentation to prove their contribution to the local economy.

The ‘Industrial Integration Rate’: A Measure of Local Value

Think of the industrial integration rate as a scorecard for a project’s local economic impact. Points are awarded for tangible contributions such as:

- Local Labor: Salaries paid to Moroccan engineers, technicians, and administrative staff.

- Local Procurement: The purchase of materials and components from Moroccan suppliers (e.g., aluminum frames, glass, junction boxes, cables).

- Local Services: Use of Moroccan companies for logistics, construction, engineering consultancy, legal, and financial services.

Simply importing finished solar panels and installing them on-site generates a very low industrial integration score, often disqualifying a bidder from the most valuable government contracts.

Why Importing Finished Modules Fails to Meet LCRs

A business model based solely on importing finished solar modules struggles to meet meaningful LCRs. Since the primary value of the core technology—the solar module—is created in another country, the only local value added is typically in logistics, customs clearance, and on-site installation labor.

While important, these contributions often represent a small fraction of the total project cost, falling far short of the required industrial integration rate. Consequently, companies that only import are at a distinct disadvantage. They cannot compete for tenders that stipulate significant local content, effectively limiting their market to smaller, private projects that do not carry the same requirements.

The Strategic Advantage of Local PV Module Assembly

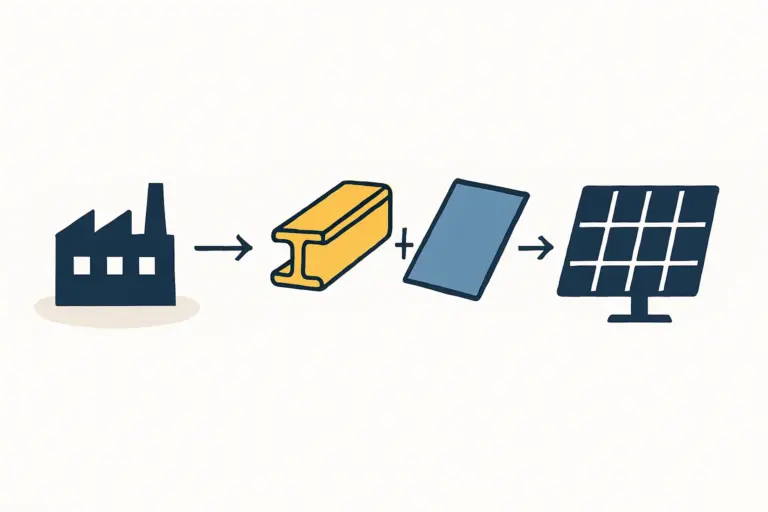

Establishing a semi-automated assembly line for solar modules within Morocco directly meets the LCR challenge. It transforms a business from a simple importer into a local industrial partner, creating significant and documentable in-country value.

Based on experience from J.v.G. turnkey projects, even a modest assembly facility (e.g., 20–50 MW annual capacity) can be a powerful tool for winning public tenders.

How Assembly Contributes to the Integration Rate

A local assembly operation adds value at multiple stages, each contributing to the required industrial integration rate:

-

Direct Local Employment: An assembly line requires a team of skilled and semi-skilled local staff, including operators, quality control technicians, maintenance engineers, and management. A 20–50 MW line typically creates 25 to 40 direct jobs.

-

Sourcing of Bill of Materials (BOM): While solar cells may initially be imported, many other components can be sourced locally over time. This includes aluminum frames, specialized solar glass, junction boxes, cables, and packaging materials. Each locally sourced component significantly increases the integration score.

-

Local Service Ecosystem: The factory itself relies on a network of local service providers for logistics, waste management, security, IT support, and maintenance, further boosting documented local spending.

-

Technology and Skills Transfer: The operation of a modern assembly line brings valuable technical knowledge and quality management processes (like ISO 9001) into the country. This commitment aligns with the strategic goals of agencies like MASEN and is viewed favorably in tender evaluations. By setting up a turnkey solar panel production line, an investor demonstrates a long-term commitment to the country’s industrial development.

Documenting and Proving Local Content: A Practical Guide

To successfully leverage a local assembly operation in a public tender, meticulous documentation is essential. Bidders must be prepared to submit a comprehensive file proving their industrial integration rate.

Key Documentation

- Employment Records: Contracts and payroll information for all local employees.

- Supplier Invoices: Verifiable invoices from Moroccan suppliers for all locally procured materials and components.

- Service Contracts: Agreements with local logistics, security, and maintenance firms.

- Production Reports: Detailed reports showing the transformation of raw materials into finished modules within the Moroccan facility.

- Company Registrations: Proof that the operating entity is legally established in Morocco.

Working with Authorities

Engaging with agencies like MASEN or ONEE early in the process is beneficial. They often provide guidelines on how the industrial integration rate is calculated and what documentation is expected. A transparent and well-documented approach builds trust and demonstrates a serious commitment to the country’s development goals.

Frequently Asked Questions (FAQ)

How much local content is typically required?

This varies by tender. Some may specify a minimum percentage (e.g., 30-40%), while others use a competitive system where bids with higher local content scores are favored. The trend is toward increasing requirements over time.

Do I need a full factory that produces everything from sand?

No. The strategic entry point is module assembly. This involves importing the solar cells—the most technologically complex component—and completing the final, value-intensive manufacturing steps in-country. This provides the best balance of investment and local content contribution. Understanding the difference between module assembly and cell production is key to developing a sound business plan.

What is the typical investment for a local assembly line?

For a semi-automated line with an annual capacity of 20 to 50 MW, the initial investment for machinery, setup, and training is typically in the range of 1.5 to 3.5 million EUR. This is significantly lower than the cost of establishing cell production.

How long does it take to set up an assembly line?

With a structured, turnkey approach, a solar module assembly line can be fully operational in under 12 months, from initial planning to the production of the first certified modules.

Can I source all materials for a solar module in Morocco?

Initially, this is unlikely. High-purity components like solar cells and EVA encapsulant will almost certainly need to be imported. However, a key part of the strategy is to progressively increase local sourcing for items like aluminum frames, glass, and junction boxes as the local supply chain develops.

Conclusion: From Importer to Industrial Partner

For entrepreneurs and investors targeting Morocco’s government-led solar projects, the message is clear: the business model must evolve from importation to local production. Local Content Requirements are not a barrier but a strategic directive.

By establishing an in-country module assembly facility, a business can meet and exceed these requirements, secure a powerful competitive advantage in public tenders, and become a long-term partner in Morocco’s sustainable energy future. The process requires careful planning, but the rewards include access to the region’s largest and most stable energy projects. For those ready to take the next step, outlining the first steps toward establishing a solar module factory is a logical starting point.