An investor new to the solar industry often focuses on production machinery, the building, and the business plan. Many assume that connecting to the local power grid and water supply is a simple administrative step. In practice, securing stable and sufficient utility infrastructure is one of the most complex and critical challenges in establishing a solar manufacturing facility, especially in a market as dynamic as Morocco.

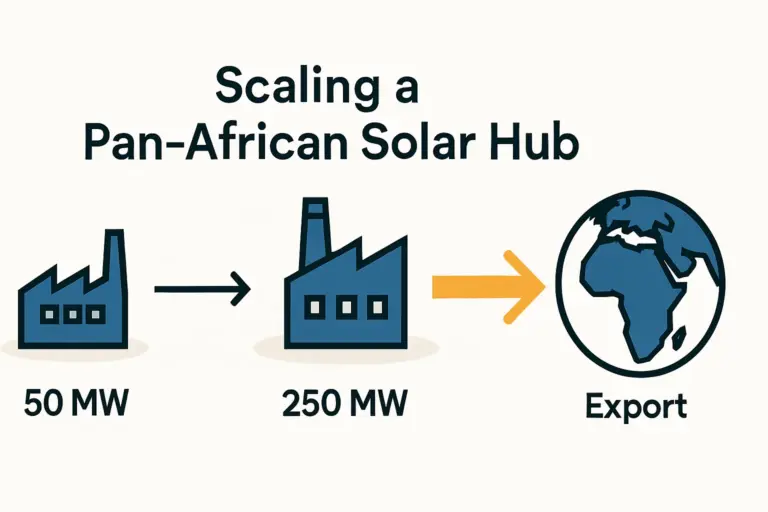

Overlooking this stage can lead to significant delays and budget overruns. A factory full of state-of-the-art equipment is of little use if the power supply is unstable or the water connection cannot be secured for months. Morocco, with its ambitious goal of achieving 52% of its energy from renewable sources by 2030, presents a tremendous opportunity. However, success hinges on navigating its unique infrastructural landscape with careful planning and technical foresight. This guide outlines the essential power and water considerations for setting up a 50 MW solar module factory in the country.

The Strategic Importance of Location: Beyond Land Cost

The choice of location for a solar factory extends far beyond the price per square meter. While proximity to ports and labor is important, access to robust utility infrastructure is paramount. Morocco’s industrial zones are concentrated, but their capacity to support energy-intensive operations varies significantly.

Industrial hubs along the Casablanca-Rabat-Tanger corridor generally offer more reliable infrastructure. In contrast, developing a facility in southern regions, while potentially offering lower land costs and proximity to large-scale solar farms, may present considerable challenges with grid stability and water availability. A thorough feasibility study must assess local utility capacity before any land is acquired.

This analysis is a cornerstone of the site selection process. A comprehensive approach to choosing the right location for your solar factory weighs the trade-offs between land cost, logistics, and the reliability of essential services like power and water.

Securing a Stable Power Supply: The Lifeblood of Your Operation

A solar module production line is a sophisticated, continuous operation highly sensitive to power quality. Interruptions or fluctuations can halt production, damage sensitive equipment, and cause significant financial losses.

Understanding Your Factory’s Power Appetite

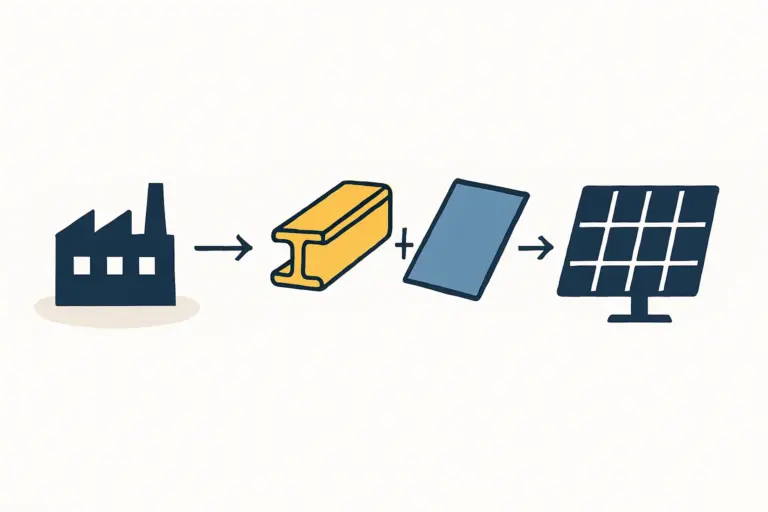

A typical 50 MW solar module production facility requires a continuous power supply of approximately 1 MW. This energy powers more than just the main production equipment; it also runs essential support systems:

- Laminators: These are the most power-intensive machines, using heat and pressure to encapsulate the solar cells.

- Stringers: Automated machines that solder cells together require precise, uninterrupted power.

- Climate Control (HVAC): Maintaining a clean, temperature- and humidity-controlled environment is crucial for product quality and requires significant energy.

- Compressed Air Systems: Pneumatic controls on various machines rely on a constant supply of compressed air.

With such high demand, a standard low-voltage connection is insufficient. The factory will require a dedicated medium-voltage connection from the public grid.

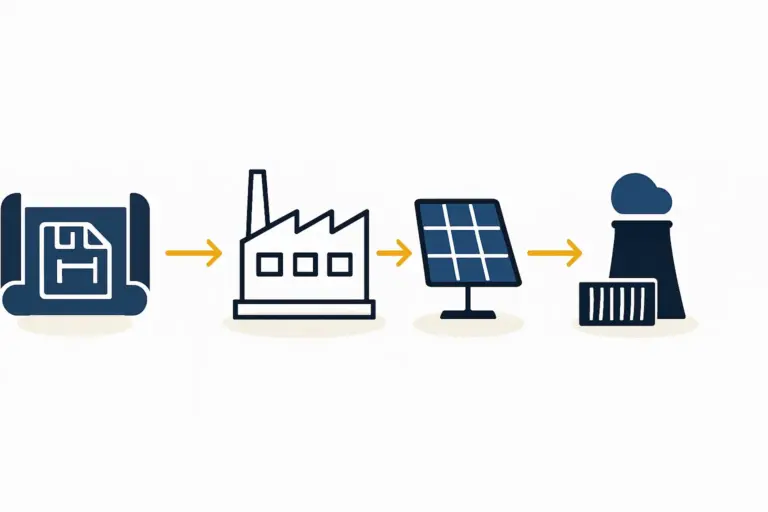

Navigating the Grid Connection with ONEE

The Office National de l’Électricité et de l’Eau Potable (ONEE) is the state-owned utility responsible for electricity and water distribution in Morocco. Engaging with ONEE is a critical, and often lengthy, part of the setup process.

The procedure typically involves:

-

Application and Feasibility Study: The investor submits a formal request detailing the factory’s power requirements. ONEE then conducts a study to determine the nearest connection point and the necessary upgrades to its network.

-

Infrastructure Development: This phase usually requires the construction of a dedicated substation on or near the factory premises. The investor is often responsible for financing this infrastructure, which includes medium-voltage switchgear and a step-down transformer (e.g., from 22 kV to 400 V).

-

Approval and Commissioning: The process concludes with a final inspection and approval before the connection is energized.

This entire process can take anywhere from 6 to 12 months and must be initiated at the earliest stages of project planning.

The Critical Question of Grid Stability

While Morocco’s national grid is relatively robust, regional stability can vary. Power sags, spikes, or brief outages can wreak havoc on automated production lines. In areas with less stable grids, particularly those further from the main economic centers, a backup power strategy is not optional—it is essential.

For a 1 MW demand, this typically involves installing one or more diesel generators equipped with an automatic transfer switch (ATS). This system can detect a grid failure and switch to backup power within seconds, protecting the essential machines for a 50 MW production line and preventing costly downtime.

Managing Water Resources in an Arid Climate

Morocco is a water-stressed country, a fact that has become a central element of its national economic strategy. For an industrial project, securing a reliable water source requires a responsible and technically sound approach.

Quantifying Water Needs for Solar Module Production

While not as water-intensive as other industries, a solar factory has consistent daily water needs. The primary uses include:

- Glass Washing: Solar glass must be perfectly clean before lamination. This process requires purified, demineralized water to avoid leaving mineral deposits.

- Machine Cooling: Certain equipment, like laminators, may use water in their cooling circuits.

- Domestic Use: With 30 to 50 employees, the facility requires water for sanitation and other daily needs.

A 50 MW factory might require between 5,000 and 10,000 liters of water per day, depending on the specific technology and efficiency measures in place.

Sourcing Water: Challenges and Solutions in Morocco

In a country conscious of water scarcity, investors have several options to consider, each with distinct advantages and challenges.

- Municipal Connection (ONEE): Connecting to the public water network is the most straightforward option where available. However, in some industrial zones, capacity may be limited, and the risk of water rationing during periods of drought is a real business consideration.

- Drilling a Private Well: This offers independence from the public network but is a complex undertaking. It requires geological surveys to assess the water table, extensive permitting from local water basin authorities (Agences de Bassin Hydraulique), and significant upfront investment. Long-term sustainability can also be a concern.

- Water Recycling Systems: The most forward-thinking and resilient solution is investing in a closed-loop water treatment and recycling system. These systems can capture, treat, and reuse up to 90% of a factory’s process water. This approach drastically reduces the daily intake required from external sources, lowers operational costs, and demonstrates strong corporate responsibility.

Investing in water recycling technology aligns with Morocco’s national priorities and significantly de-risks the operation against future water shortages.

Integrating Infrastructure Planning into Your Project Timeline

A key insight from J.v.G. Technology’s experience with turnkey projects is that utility connections dictate the project timeline. The 6-to-12-month period required for securing power and water often defines the critical path.

Applications and technical studies with ONEE must begin concurrently with building design and machine procurement. Any delay in this process will inevitably postpone the start of production. Factoring these timelines into the full turnkey solar factory setup process from day one prevents costly surprises and ensures a coordinated, efficient project execution.

Frequently Asked Questions (FAQ)

What is the typical cost for a medium-voltage grid connection in Morocco?

The cost can vary widely, from €50,000 to over €250,000. It depends heavily on the distance to the nearest suitable grid line and the extent of the required network upgrades and substation construction. A detailed study by ONEE is necessary for an accurate budget.

Can a solar factory run on its own solar power?

While it seems logical, it isn’t practical for the primary manufacturing load. A 1 MW rooftop or ground-mounted solar system would be required to meet the factory’s continuous demand, including at night, which would necessitate a very large and expensive battery storage system. Using a PV system to offset a portion of electricity consumption and reduce operational costs is more feasible, but grid power remains essential for stable, 24/7 production.

How does poor water quality affect module production?

Using untreated water for cleaning glass can leave mineral residues (calcium, magnesium) after drying. These deposits can compromise the adhesion of the encapsulant during lamination, leading to delamination and long-term reliability issues in the finished solar modules. This is why a demineralization system is a standard requirement.

What role does the local government play in securing utilities?

Regional investment centers (Centres Régionaux d’Investissement) and the authorities managing specific industrial zones can act as facilitators. They can provide initial information on infrastructure availability and assist in coordinating with utilities like ONEE. However, the technical and financial responsibility for the connection ultimately lies with the investor.

Conclusion: Building on a Solid Foundation

Establishing a solar module factory in Morocco is a venture with immense potential, supported by a clear national vision. However, success is built not just on advanced machinery but on the bedrock of reliable infrastructure.

Thorough due diligence on power and water availability at the site selection stage is non-negotiable. Proactive engagement with local utilities, realistic timeline planning, and strategic investments in backup power and water recycling are essential risk-mitigation measures. Understanding these foundational requirements is the first step toward building a successful and resilient manufacturing operation that can thrive in one of North Africa’s most promising solar markets.