Disclaimer: This case study represents a composite example derived from real-world

consulting work by J.v.G. Technology GmbH in solar module production and factory optimization. All data points are realistic but simplified for clarity and educational purposes.

For entrepreneurs and investors surveying the global landscape, few regions present an opportunity as clear as West Africa. The region faces a significant energy deficit, where its rapidly growing economies are constrained by unreliable and insufficient power infrastructure. This gap between demand and supply is more than a challenge—it is a multi-billion dollar market opening for decentralized, reliable energy solutions.

This strategic blueprint outlines the compelling case for establishing a solar module factory in Morocco as a manufacturing and logistics hub for West Africa’s burgeoning off-grid and commercial & industrial (C&I) solar sectors.

The Compelling Case for West Africa’s C&I and Off-Grid Solar Market

West Africa’s demand for electricity is growing at an estimated 8% annually, yet national grids struggle to keep pace. Businesses frequently suffer from power outages, forcing them to rely on expensive and polluting diesel generators—a reality that severely hampers productivity and economic growth.

For the commercial and industrial sector, the engine of the region’s economy, stable power is not a luxury but a necessity. Solar photovoltaic (PV) systems offer a direct solution, delivering cost savings, energy independence, and operational stability.

At the same time, vast rural populations remain without access to any form of electricity. Off-grid solar solutions, from small home systems to community microgrids, represent the most viable path to electrification, unlocking social and economic development. This convergence of industrial need and rural demand creates a sustainable, high-volume market for solar modules tailored to the region’s specific environmental conditions.

Why Morocco is the Ideal Manufacturing Hub

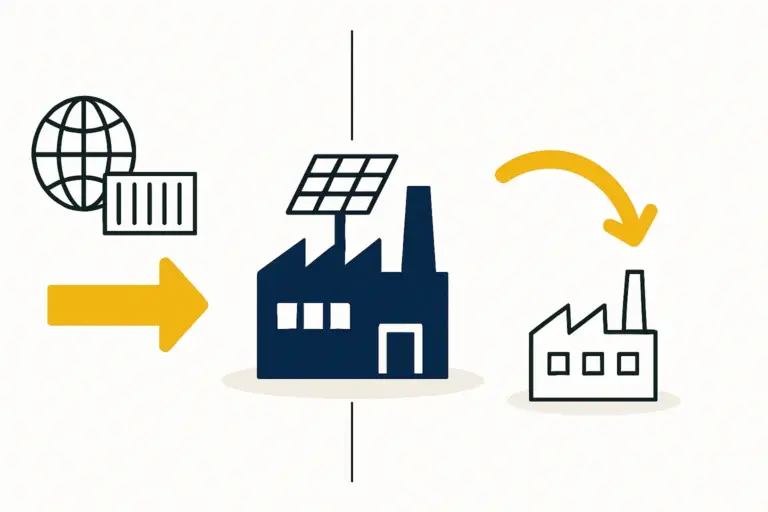

While establishing a factory directly within a target market like Nigeria or Ghana might seem logical, a hub-and-spoke model based in Morocco offers superior strategic advantages that significantly de-risk the investment.

Geopolitical Stability and Pro-Business Environment

Morocco is known for its political stability and has actively cultivated a business-friendly climate. The government offers significant investment incentives, particularly in designated economic zones like Laâyoune, which can include tax exemptions and streamlined administrative processes.

World-Class Logistics

The port of Tanger Med is one of the largest and most efficient in Africa, offering a strategic gateway to global supply chains and West African maritime routes. This infrastructure ensures the reliable importation of raw materials and efficient exportation of finished solar modules.

Favorable Trade Agreements

Morocco holds observer status with the Economic Community of West African States (ECOWAS) and has numerous bilateral free trade agreements. These agreements reduce tariffs and simplify cross-border commerce, providing a crucial competitive advantage over manufacturers from outside the continent.

The Product Strategy: Manufacturing for Regional Demands

Success in the African market requires more than just a standard solar panel. The environmental conditions—high ambient temperatures, intense solar irradiation, and seasonal dust—demand a more robust design.

This plan focuses on producing the DESERT+ series of solar modules, specifically engineered for hot and arid climates. Unlike standard modules, these are designed for long-term durability and sustained energy yield in harsh conditions. A key feature is the use of glass-glass solar panels, which offer superior protection against humidity, mechanical stress, and heat-related degradation compared to conventional glass-foil designs.

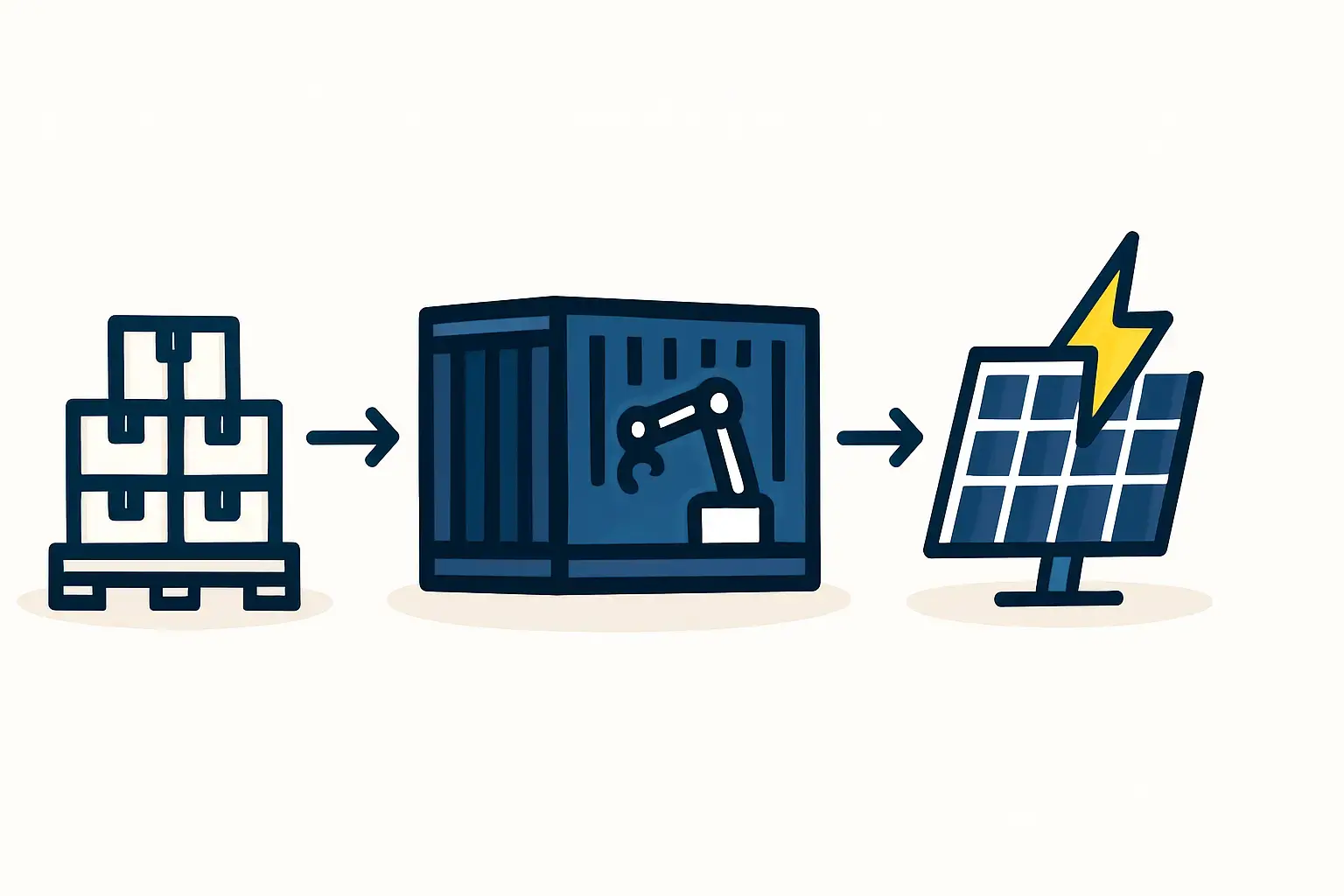

The production of these specialized modules can be established efficiently with a turnkey solar production line. This approach, often implemented by experienced engineering firms like an established European industrial solutions provider, allows a new market entrant to deploy a proven, fully integrated manufacturing process with predictable outputs and quality standards from day one.

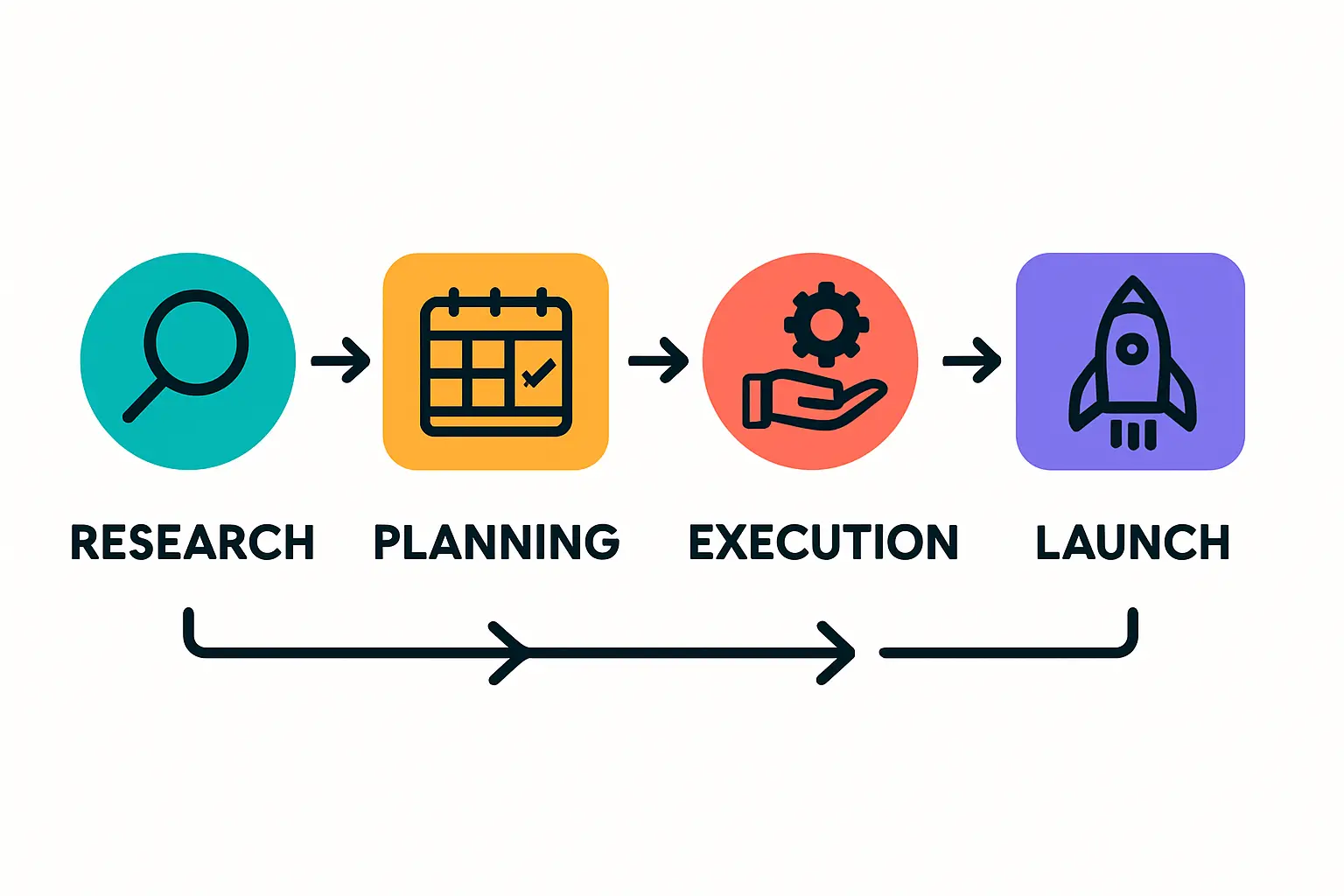

A Structured Approach to Market Entry and Growth

Launching a manufacturing venture in a new region requires a meticulous, structured approach. The planning and execution framework developed by the experienced European turnkey engineering team, refined over decades of consulting in emerging markets, offers a clear roadmap.

Step 1: Securing Project and Export Financing

One of the primary hurdles for large-scale projects in Africa is access to suitable financing. This model mitigates that risk by aligning the project with the mandates of regional development banks. Institutions such as the African Development Bank (AfDB) and the West African Development Bank (BOAD) are chartered to support projects that foster regional integration, promote renewable energy, and create local employment.

By positioning the Moroccan factory as a hub for West African energy independence, the project becomes highly attractive to the export financing facilities these banks offer. This secures the necessary capital while adding a layer of institutional credibility.

Step 2: Building a Resilient Distribution Network

Manufacturing a superior product is only the first step; the route to market is equally critical. A successful strategy depends on a robust distribution network of trusted local partners in key target countries like Senegal, Ivory Coast, Ghana, and Nigeria.

This network would include:

- Local solar installation companies serving the C&I sector.

- Distributors specializing in renewable energy components.

- Non-governmental organizations and development agencies running rural electrification programs.

This approach ensures the modules reach end-users efficiently and leverages local market knowledge and relationships.

Step 3: Localisation and Skill Development

A core principle of this model is sustainable development. The factory in Morocco would not only produce solar panels but also become a center for knowledge transfer. The project plan must include comprehensive training for local technicians, engineers, and operators. This investment in solar factory manpower creates skilled employment opportunities, contributes directly to the local economy, and builds a sustainable operational foundation.

Investment Profile: A 50 MW Factory in Laâyoune

To put this strategic concept into tangible terms, consider the baseline scenario for a 50 MW per year manufacturing facility in Laâyoune.

- Capacity: 50 MW/annum, capable of producing approximately 125,000 modules per year (at 400 Wp).

- Facility Size: Requires an industrial building of approximately 3,000–4,000 square meters.

- Workforce: Employs between 50 and 70 staff, including operators, technicians, and administrative personnel.

- Timeline: Based on experience gained from European PV manufacturers’ turnkey projects, a facility of this scale can be fully operational within 12 to 18 months of the project’s financial close.

Frequently Asked Questions (FAQ)

Why not manufacture directly in a larger market like Nigeria?

While direct manufacturing has its merits, the ‘hub’ model in Morocco offers a more stable and de-risked platform. Morocco’s superior logistical infrastructure, political stability, and comprehensive free trade agreements create a more secure environment for a capital-intensive investment. It allows the business to serve multiple West African markets from a single, efficient, and predictable base.

What is the typical timeline for setting up such a factory?

A well-structured project using a turnkey line solution can move from planning to full production remarkably quickly. A realistic timeline is 12 to 18 months, encompassing site preparation, equipment procurement and installation, staff training, and initial certification audits.

Is deep solar expertise required for an entrepreneur to start this venture?

No. The most critical requirement is a strong business and project management background. Partnering with an experienced engineering firm that provides the turnkey production line, process knowledge, and operational training addresses the technical complexities of manufacturing. The core message of platforms like pvknowhow.com is that the right guidance can bridge the technical gap.

How do DESERT+ modules specifically benefit the C&I sector?

For a business, a solar investment is evaluated on its long-term return. DESERT+ modules, with their robust glass-glass construction, are built to withstand high temperatures and harsh conditions with minimal degradation. This means they produce more energy over their 30-year lifespan, delivering a higher, more reliable return on investment for the factory, hotel, or agricultural enterprise that installs them.

Conclusion and Path Forward

The establishment of a solar module factory in Morocco is more than an industrial project; it is a strategic investment in the economic future of West Africa. The combination of massive market demand, a prime manufacturing location, a purpose-built product, and a viable financing and distribution model creates a uniquely compelling business case.

This approach offers the opportunity to build a profitable enterprise and contribute tangibly to the region’s sustainable development. For investors ready to take the next step, gaining a deep understanding of the solar panel manufacturing process is the foundation for turning this strategic vision into a reality.

Download the West African Solar Market Expansion Case Study [PDF]

Author: This case study was prepared by the

turnkey solar module production specialists at J.V.G. Technology GmbH

It is based on real data and consulting experience from J.v.G. projects

worldwide, including installations ranging from 20 MW to 500 MW capacity.