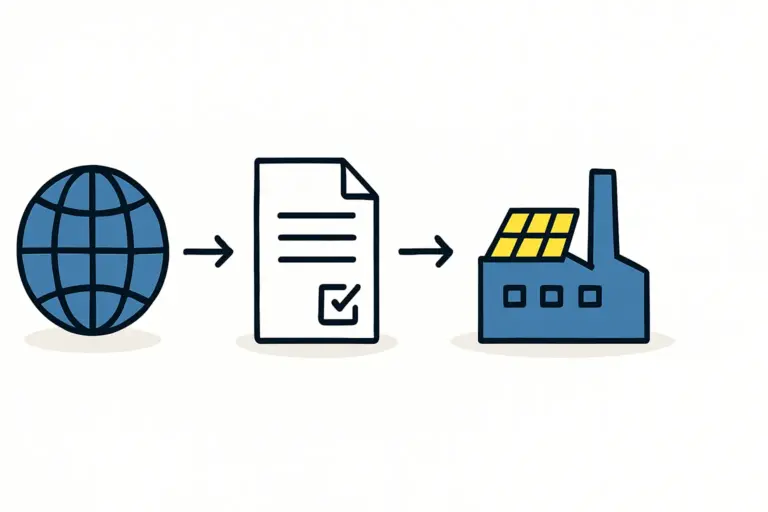

Recent government directives in Myanmar are encouraging domestic solar panel production as a solution to the country’s significant energy shortages. For entrepreneurs and investors looking to enter this emerging market, this government support presents a compelling opportunity, but it also raises a fundamental operational question: where will the raw materials for these factories come from?

The success of any solar manufacturing venture hinges on a reliable, cost-effective, and high-quality supply chain. This article offers a detailed analysis for business professionals considering this venture in Myanmar, comparing the feasibility of sourcing components locally versus importing from established international hubs. Striking the right balance is the first step toward building a resilient and profitable operation.

Understanding the Core Components of a Solar Module

Before evaluating sourcing options, it’s essential to understand the primary materials involved. A typical solar panel is an assembly of several specialized components, each with its own manufacturing requirements. These items are detailed in a Bill of Materials (BOM), which serves as the factory’s foundational shopping list.

The main components include:

- Solar Glass: A highly transparent, low-iron, tempered glass that protects the solar cells while maximizing light absorption.

- Aluminum Frames: Extruded aluminum profiles that provide structural integrity and a means for mounting the panel.

- Solar Cells: The core technological component that converts sunlight into electricity. These are highly sophisticated semiconductor devices.

- Encapsulant (EVA): Ethylene Vinyl Acetate is a polymer sheet used to laminate the components together, providing adhesion and insulation.

- Backsheet: A durable, multi-layer polymer film on the rear of the panel that protects against moisture and provides electrical insulation.

- Junction Box: An enclosure on the back of the panel containing bypass diodes and the connection cables.

Each of these materials must meet strict international quality standards for the final solar module to be certified and considered bankable by project financiers.

The Case for International Sourcing: Reliability and Scale

For most new entrants into the solar manufacturing industry, importing components from established international suppliers is the standard approach. This strategy provides a clear path to market with predictable quality and costs.

Access to Established Supply Hubs

Regional manufacturing powerhouses—particularly China, but also Thailand and Vietnam—have mature, highly developed supply chains for every solar component. These suppliers offer decades of experience, massive economies of scale, and extensive product catalogues. For a new factory in Myanmar, these hubs are geographically close, providing a logistical advantage over sourcing from Europe or North America.

Quality and Certification

International component suppliers typically hold certifications from recognized bodies like TÜV Rheinland. Using pre-certified components significantly simplifies the complex and costly process of getting the final solar module certified under IEC 61215 and IEC 61730 standards. This de-risks the market entry process and is often a non-negotiable requirement for project developers and financiers.

Cost-Effectiveness at Scale

The sheer production volume of international suppliers allows them to offer competitive pricing that is difficult for a new, local manufacturer to match. This cost advantage applies to nearly all components, from solar cells to junction boxes.

Potential Challenges

Despite these benefits, an international sourcing strategy comes with its own set of challenges. These include:

- Logistical Complexity: Managing international shipping, customs clearance, and potential delays.

- Import Duties and Taxes: Tariffs can significantly impact the final cost of materials.

- Currency Fluctuations: Exposure to foreign exchange risk can affect profitability.

- Longer Lead Times: Compared to local sourcing, international shipping can extend production timelines.

Exploring Local Sourcing in Myanmar: Potential and Pitfalls

The call from Myanmar’s leadership to use domestic raw materials like silica and aluminum is strategically sound. A robust local supply chain can offer significant long-term advantages, including reduced logistical costs, shorter lead times, support for the national economy, and potential government incentives.

However, the transition from raw material availability to finished, high-quality solar components demands a realistic assessment.

Assessing Local Manufacturing Capabilities

- Solar Glass: While Myanmar may have silica sand deposits, the production of solar-grade, low-iron, patterned, and tempered glass is a highly specialized industrial process. It is unlikely that existing glass manufacturers in the country currently possess this capability without significant investment and technology transfer.

- Aluminum Frames: Similarly, while aluminum may be available, extruding frames to the precise dimensions and tolerances required by automated solar manufacturing equipment is critical. Any deviation can lead to production line stoppages and quality issues.

- Specialized Components: Items like solar cells, EVA, backsheets, and certified junction boxes are the products of advanced chemical and electronics manufacturing. Developing this capacity locally would be a long-term, capital-intensive endeavor.

Based on experience from J.v.G. turnkey projects in emerging markets, building these specialized local supply industries from the ground up often takes several years and substantial investment.

A Hybrid Approach: The Most Practical Strategy for New Entrants

For an entrepreneur starting a solar panel factory in Myanmar, the most practical and lowest-risk strategy is a hybrid sourcing model. This approach balances the immediate need for quality and reliability with the long-term goal of localization.

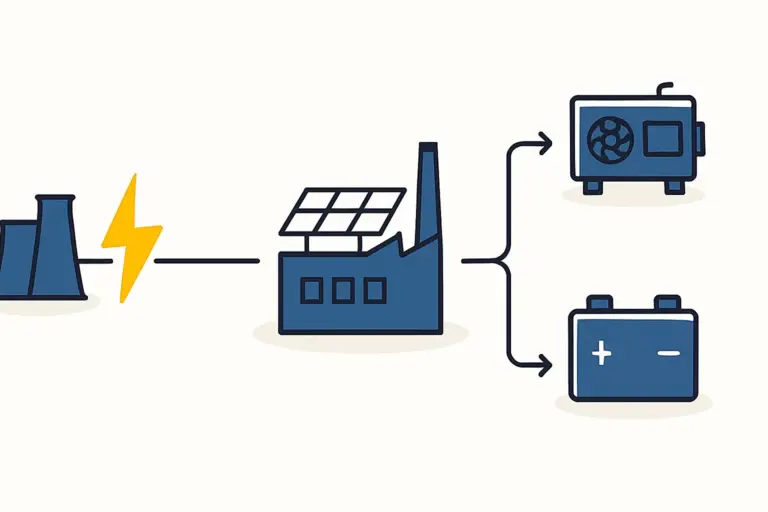

Phase 1: Import Core and Critical Components

Begin operations by importing all critical, high-technology components—including solar cells, EVA, backsheets, and certified junction boxes—from reputable international suppliers. Doing so ensures the factory can produce certified, bankable modules from day one.

Phase 2: Develop Local Sourcing for Bulk Materials

Simultaneously, the new enterprise should begin developing local supply chains for the bulkiest and most transport-sensitive components: glass and aluminum frames. This could involve:

- Partnering: Collaborating with existing local aluminum extruders or glass manufacturers to help them upgrade their equipment and processes to meet solar industry standards.

- Investing: Directly investing in or establishing a dedicated local facility for frame extrusion or glass tempering.

This phased approach allows the factory to become operational quickly while building a sustainable and cost-effective local supply chain over time.

Frequently Asked Questions (FAQ)

Are solar cells produced in Myanmar?

Currently, there is no large-scale commercial production of solar cells in Myanmar. For the foreseeable future, these critical components will need to be imported from specialized manufacturers in China, Southeast Asia, or Europe.

What is the most difficult component to source locally?

Aside from solar cells, high-quality encapsulants (EVA) and backsheets are particularly challenging to source locally in a new market. These materials require a sophisticated chemical industry and rigorous quality control to ensure a 25-year lifespan for the solar module.

Can a factory start with 100% imported materials and switch to local sourcing later?

Yes, this is a common and highly recommended strategy. It allows the business to focus initially on mastering the module assembly process. As the operation matures, the business can then strategically shift certain components to local suppliers once they meet the required quality and cost parameters.

Do local materials need special certification?

Absolutely. Every single component in a solar module, regardless of its origin, must meet the specific requirements of international standards (like IEC). The final module will undergo rigorous testing, and the failure of any single component, whether local or imported, will result in the entire module failing certification.

Conclusion and Next Steps

The push for domestic solar panel manufacturing in Myanmar presents a landmark opportunity for investors. However, success depends on a clear-eyed and strategic approach to building the supply chain. A hybrid model—importing specialized components while strategically developing local suppliers for bulk materials like glass and frames—offers the most balanced and pragmatic path forward.

This strategy mitigates the initial risks associated with quality and certification while laying the groundwork for a more resilient, cost-effective, and nationally integrated operation. Navigating these supply chain complexities is a foundational step toward building a successful solar manufacturing business. A well-structured plan, based on deep industry experience, is key to mitigating risks and optimizing for long-term growth.