An investor considering a solar module factory in Namibia might first look at the local labor market and ask a critical question: ‘Where will we find experienced technicians to run a modern production line?’

It’s a valid concern for any entrepreneur entering the solar industry. However, experience from successful factories in emerging markets shows that the most effective strategy is not to find a pre-existing workforce, but to build one.

With a strategic approach to recruitment and a structured, hands-on training program, Namibia’s motivated labor pool is a significant asset, not a liability. This guide outlines a practical framework for developing a highly skilled local team capable of operating a world-class solar module manufacturing facility.

The Namibian Labor Context: A Foundation of Potential

An effective workforce strategy begins with a clear understanding of the local environment. Namibia presents a unique combination of challenges and opportunities that, addressed correctly, can create a competitive operational advantage.

The country has a substantial, youthful population eager for skilled employment. According to the Namibia Statistics Agency’s 2018 Labour Force Survey, over 200,000 individuals were unemployed, with youth unemployment at a striking 46.1%. This indicates a large, available talent pool for new industrial projects.

The Namibian government has also shown a commitment to enhancing the country’s technical capabilities. The Harambee Prosperity Plan II emphasizes the importance of Technical and Vocational Education and Training (TVET) to support industrialization. A 2022 GIZ study on behalf of the German government, focusing on Namibia’s green hydrogen economy, identified a clear need for skilled artisans and technicians. While this points to a skills gap, it also confirms that an initiative providing high-quality technical training aligns directly with national development goals.

The key is to view this landscape not as a deficit of solar-specific experience, but as an opportunity to recruit individuals with foundational aptitudes and mold them into specialists through a dedicated program.

Core Competencies for Modern Solar Module Production

A common misconception is that a solar panel factory requires a large team of advanced engineers. In reality, the day-to-day operation of a semi-automated production line relies on skills that are highly trainable: process discipline, attention to detail, and a commitment to quality control.

The operational success of a solar factory hinges on mastering each production step. The manufacturing process breaks down into several key stages, each requiring specific operator skills rather than deep theoretical knowledge.

The primary roles within a typical 20-50 MW factory include:

- Machine Operators: Responsible for loading materials and overseeing specific stations like the stringer, layup station, and laminator. The critical skills for this role are consistency and the ability to follow standard procedures.

- Quality Control Inspectors: Tasked with visual inspection, EL testing, and sun simulation tests to ensure every module meets international standards. This role demands meticulous attention to detail.

- Maintenance Technicians: These roles are ideal for individuals with a background in mechanics or electronics who can perform routine maintenance and troubleshoot minor issues. Graduates from local Vocational Training Centres (VTCs) are often excellent candidates.

- Line Supervisors: Team leaders who oversee a shift, manage workflow, and ensure production targets and quality benchmarks are met.

These competencies are not unique to the solar industry. They are the bedrock of any modern manufacturing operation, from food processing to automotive assembly.

A Practical Recruitment Strategy for Namibia

Since prior solar manufacturing experience will be virtually nonexistent in the local market, the recruitment process should focus on aptitude and attitude rather than a specific resume history.

A successful recruitment strategy involves:

-

Targeting Aptitude: Focus on sourcing candidates from Namibia’s VTCs and institutions like the Namibia University of Science and Technology (NUST). Look for individuals with training in electrical, mechanical, or industrial fields; their foundational knowledge is an excellent starting point.

-

Looking Beyond Solar: Widen the search to individuals with experience in any regulated manufacturing environment. A technician from a bottling plant who understands quality control and production line dynamics is often a more valuable candidate than someone with unrelated academic qualifications.

-

Implementing Practical Assessments: During interviews, use hands-on tests to assess manual dexterity, logical problem-solving, and the ability to follow complex instructions. These assessments provide far more insight into a candidate’s potential than a conversation alone.

-

Prioritizing a Learning Mindset: The most important attribute is a willingness to learn and adapt. A proactive, reliable, and motivated team is the foundation for a successful ramp-up and long-term operational excellence.

By focusing on these core traits, an investor can assemble a team with the intrinsic qualities needed to excel in a high-tech manufacturing environment.

The Cornerstone: A Structured Training Framework

A robust, multi-phased training program is what transforms a team of promising recruits into skilled specialists. This program is arguably the single most critical investment in the factory’s long-term success.

Based on experience from J.v.G. Technology GmbH turnkey projects, a successful training program is built around three distinct phases.

Phase 1: Foundational Classroom Training

This initial phase, lasting one to two weeks, covers the theoretical knowledge every employee needs. Topics include:

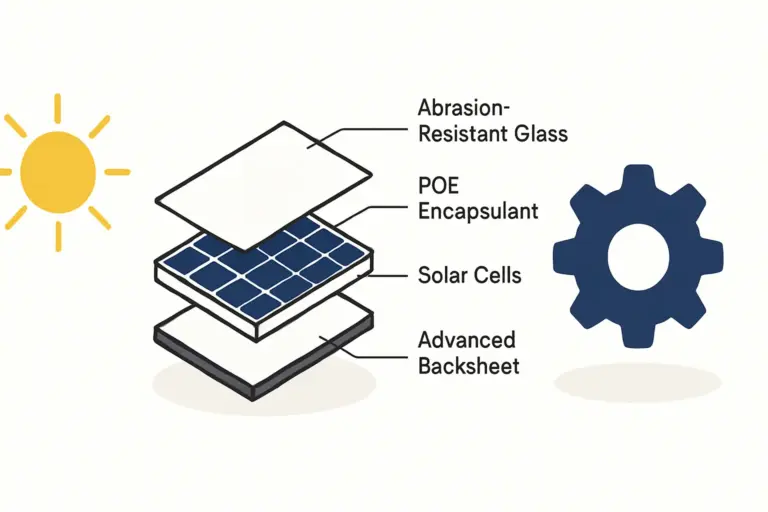

- PV Technology Basics: How a solar cell works and how modules are constructed.

- Material Science: Understanding the properties of glass, EVA, backsheets, and cells.

- Quality Standards: An introduction to IEC standards and the importance of ISO 9001 principles.

- Workplace Safety: Comprehensive training on handling materials and operating machinery safely.

Phase 2: Hands-On Equipment Training

This is the most critical phase, where theory is put into practice. Led by engineers from the equipment supplier commissioning the production line, trainees learn to operate each piece of machinery, from the cell tester to the final framing station. Understanding the key solar panel manufacturing machines is central to this phase, and the direct knowledge transfer from machine experts is invaluable.

Phase 3: Supervised Production Ramp-Up

Once the team is familiar with the equipment, the final phase involves running the line, initially at a slower pace or with non-critical materials. This allows the team to build rhythm, refine communication, and master the workflow together. Under the guidance of supervisors and external experts, the team receives continuous feedback, correcting errors and optimizing processes until the line is ready for full-capacity production.

Ensuring Long-Term Success Through Local Leadership

The ultimate goal is to create a self-sufficient, locally managed operation. From the first cohort of trainees, it is vital to identify individuals who demonstrate leadership potential. These candidates should be given additional responsibilities and mentored to become the next generation of line supervisors, quality managers, and maintenance heads.

This ‘train-the-trainer’ approach not only ensures operational continuity but also creates clear career paths. It fosters loyalty, reduces long-term reliance on expatriate personnel, and embeds technical expertise deeply within the local organization, securing the investment for years to come.

Frequently Asked Questions (FAQ)

How many employees are required for a 20-50 MW solar module factory?

A typical single-shift operation for a factory of this size requires 25 to 35 employees. This includes machine operators, quality control personnel, maintenance technicians, and essential administrative and logistics staff.

Is it necessary to hire personnel with advanced engineering degrees?

Not for most operational roles. The key requirement is for trainable individuals with strong attention to detail and process discipline. While a plant manager or head of engineering would typically hold a relevant degree, the majority of the workforce can be sourced effectively from vocational training centers or other manufacturing backgrounds.

What is the typical duration of an initial training program?

A comprehensive initial program, including both classroom theory and hands-on equipment training, generally lasts between four and eight weeks. This is followed by a multi-week period of supervised production ramp-up to solidify skills and streamline operations.

Can workers from industries like food processing or textiles be retrained for solar manufacturing?

Yes, absolutely. These workers often have valuable, directly transferable skills in process adherence, safety protocols, and quality assurance. Their experience in a structured manufacturing environment makes them excellent candidates for retraining.

What is the long-term role of expatriate specialists?

Initially, expatriate experts—often from the equipment supplier or a technical partner like J.v.G. Technology GmbH—are crucial for commissioning the production line and leading the initial training. Their role then shifts from direct management to mentorship and advisory, with the primary goal of developing a fully autonomous local management team.