With the site for a new solar module factory in Namibia finalized, financing secured, and machinery specifications approved, an entrepreneur faces a critical challenge: how to transport a multi-million-dollar production line and a steady supply of raw materials from suppliers in Europe and Asia to the factory floor. The success of the entire venture hinges on this complex logistical chain.

This article offers a practical overview of using the Port of Walvis Bay for importing machinery and materials, as well as for future exports. It outlines the port’s strategic advantages, the key steps in the importation process, and considerations for inland transportation—a foundational guide for investors planning to establish a manufacturing presence in Namibia.

Why Walvis Bay is a Strategic Asset for Namibian Industrial Projects

For any industrial project in Namibia, the Port of Walvis Bay is more than just a point of entry—it is a fundamental strategic asset. Located on the west coast of Africa, it is a natural deepwater harbour renowned for its efficiency and modern infrastructure.

Unlike many regional ports that face significant congestion, Walvis Bay operates smoothly, offering predictable turnaround times. This reliability is invaluable for project managers coordinating tight installation schedules. The port’s new container terminal boasts an annual capacity of 750,000 TEUs (twenty-foot equivalent units), ensuring it can handle large volumes of cargo without delays. Such operational efficiency directly reduces the risk of costly project overruns and ensures a more stable supply chain for raw materials once production is underway.

Step 1: Importing Production Machinery and Raw Materials

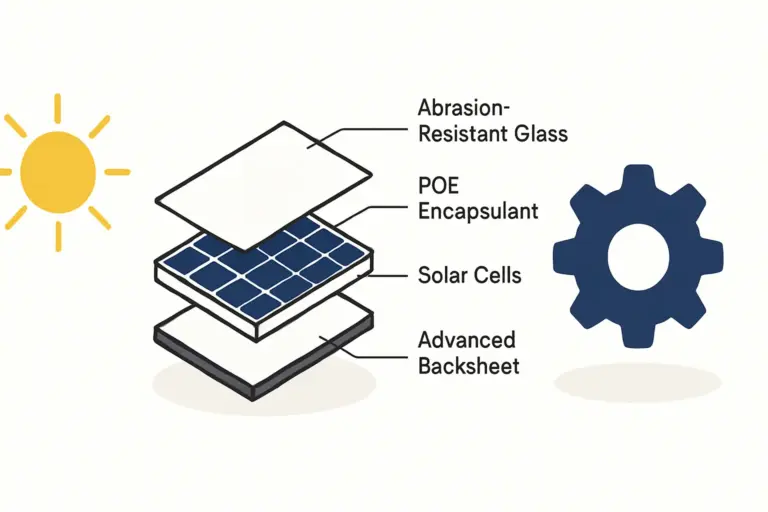

The first major logistical operation for a new solar factory is importing the manufacturing equipment itself. A complete [Link 2: Anchor: turnkey PV production line | URL: /turnkey-solar-pv-production-line] includes numerous sensitive and heavy machines, from stringers and laminators to testers and framing stations.

The process typically involves:

Specialized Packing and Shipping: Equipment is shipped in various container types, including standard 40-foot containers, open-top containers for oversized items, and flat-rack containers for heavy machinery like glass washing units or laminators.

Coordination with Freight Forwarders: Working with an experienced international freight forwarder is essential. They manage the entire process, from collection at the manufacturer’s site in Asia or Europe to delivery at the port. Their expertise in handling sensitive industrial machinery ensures proper lashing, securing, and protection against the elements during transit.

Material Supply Chain: Beyond the initial machinery, the factory will require a continuous flow of raw materials such as solar glass, EVA foil, backsheets, and aluminum frames. Establishing a reliable and cost-effective shipping route through Walvis Bay is a cornerstone of a viable [Link 1: Anchor: solar module manufacturing business plan | URL: /solar-manufacturing-business-plan].

Experience from J.v.G. turnkey projects shows that meticulous planning at this stage prevents significant delays and unforeseen costs down the line.

Step 2: Navigating Customs, Duties, and Regulations

Once a shipment arrives at Walvis Bay, it must clear Namibian customs. While this can be a point of concern for international investors, proper preparation makes the process manageable and efficient.

Namibia is a member of the Southern African Customs Union (SACU), which also includes Botswana, Lesotho, South Africa, and Eswatini. This union establishes a common external tariff for goods imported from outside the member states.

Key considerations for a factory investor include:

Import Duties on Capital Equipment: While standard duties apply to many goods, governments often provide incentives for industrial development. Many countries offer rebates or full exemptions on import duties for capital equipment intended for manufacturing, which can significantly reduce the initial [Link 3: Anchor: investment for a solar factory | URL: /investment-for-solar-factory]. Investigating these possibilities with the Namibian Investment Promotion and Development Board (NIPDB) is a critical early step.

Correct Documentation: Delays in customs are most often caused by incomplete or incorrect paperwork. Essential documents include the Bill of Lading, Commercial Invoice, Packing List, and Certificate of Origin. Any discrepancy can lead to inspections, fines, and costly storage charges at the port.

Step 3: Inland Transportation from Port to Factory Site

After clearing customs, the machinery begins its final leg of the journey from Walvis Bay to the factory site, whether it’s nearby or further inland toward Windhoek. This stage requires careful planning.

The Walvis Bay Corridors Group (WBCG) manages a network of well-maintained transport corridors connecting the port to the rest of the country and neighboring states, ensuring reliable road access for factories within Namibia. However, transporting oversized or heavy machinery often requires special permits, police escorts, and route surveys to ensure bridges and power lines can be safely navigated. A local logistics partner with experience in “abnormal load” transportation is indispensable for this phase.

The Bigger Picture: Exporting Finished Solar Modules

The logistical advantages of Walvis Bay extend beyond importation. Once the factory is operational, this same efficient port and corridor network becomes a strategic gateway for exporting finished solar modules across the Southern African Development Community (SADC) region.

Countries like Zambia, Botswana, the Democratic Republic of Congo, and Angola represent significant growth markets for solar energy. A manufacturing base in Namibia, supported by the efficient Walvis Bay-Ndola-Lubumbashi Development Corridor or the Trans-Kalahari Corridor, is exceptionally well-positioned to serve this regional demand. This export potential is a key factor in assessing the long-term profitability and strategic value of establishing a solar factory in the country.

Frequently Asked Questions (FAQ)

How long does customs clearance typically take in Walvis Bay?

While this can vary, the Port of Walvis Bay is known for its efficiency. With all documentation prepared correctly, clearance can often be completed within 3 to 5 business days, which compares favorably to other ports in the region.

Are there special economic zones (SEZs) in Walvis Bay that benefit manufacturers?

The Namibian government is actively developing its Special Economic Zone (SEZ) framework, with Walvis Bay designated as a key area. These zones are intended to offer incentives such as tax advantages and streamlined administrative processes for manufacturers and exporters, providing significant benefits for a new solar factory.

What is the most critical part of a successful importation plan?

The most critical elements are meticulous documentation and the selection of experienced logistics partners. An error in a commercial invoice or a freight forwarder unfamiliar with handling sensitive machinery can cause delays and costs that far exceed any potential savings from choosing a cheaper, less experienced provider.

How does this logistical planning fit into the overall project budget?

Logistics are a major cost component. The total investment for a solar factory must account for sea freight, insurance, customs duties (or the cost of applying for exemptions), port handling charges, and inland transportation for all machinery and initial raw material stocks.

Conclusion: Integrating Logistics into Your Business Strategy

Effective logistical planning is not an administrative afterthought; it is a core component of a successful industrial strategy. For entrepreneurs looking to enter the solar manufacturing sector in Namibia, the Port of Walvis Bay offers a world-class, reliable gateway that can de-risk project execution and enhance future export opportunities.

A firm grasp of the steps involved—from initial shipment and customs navigation to final inland delivery—is fundamental. For serious investors, the next step is to incorporate a detailed logistical analysis into their feasibility studies and business plan, ensuring that all costs, timelines, and regulatory requirements are properly addressed from the outset.