Imagine your new solar module factory is in the middle of a critical production run. The automated stringer is precisely soldering cells, and the laminator is operating at the perfect temperature. Suddenly, the lights flicker, and the machinery grinds to a halt. A grid outage has just jeopardized an entire batch of modules, damaged sensitive equipment, and triggered hours of costly downtime. For industrial investors in Nepal, this scenario is not a remote threat—it’s an operational reality demanding strategic foresight.

This article explores practical and advanced power solutions that can ensure uninterrupted operations for manufacturing facilities, even with challenging grid infrastructure. We will examine how technologies like captive power plants and battery storage can transform this major liability into a competitive advantage.

The High Cost of Unreliable Power in Manufacturing

In a modern factory, power interruptions are more than a minor inconvenience; they are a significant financial threat. The consequences extend far beyond lost production hours.

- Equipment Damage: Abrupt power cuts can severely damage sensitive, high-value machinery. The sudden shutdown of a laminator or cell tester can lead to costly repairs and extended downtime.

- Material Waste: An interruption during the solar panel manufacturing process can result in the complete loss of materials currently in production, from silicon wafers to encapsulants.

- Quality Control Issues: Inconsistent power can lead to defects that compromise the final product’s quality and performance, potentially damaging the brand’s reputation and leading to warranty claims.

- Reduced Throughput: Frequent, short interruptions add up, systematically reducing a factory’s overall output and efficiency over time.

For a capital-intensive venture like a solar module factory, ensuring a stable, high-quality power supply is not an operational goal—it is a foundational requirement for success.

Understanding Nepal’s Unique Energy Landscape

Nepal presents a unique energy paradox. The country has an estimated 42,000 MW of commercially viable hydropower potential, yet its installed capacity is only around 2,200 MW. This disparity creates a heavy dependence on seasonal river flows.

During the wet season (June to October), power generation is often sufficient. In the dry season, however, river flows can plummet by over 70%, creating a substantial energy deficit. This seasonal variation has historically resulted in ‘load shedding’—planned, rolling blackouts to manage the shortfall. While official load shedding has been greatly reduced for residential consumers in recent years, industrial sectors can still face instability and poor power quality from an overloaded and aging transmission infrastructure.

For any industrial investor in Nepal, this context makes planning for energy self-sufficiency essential from day one.

Strategic Solutions for Energy Independence

Relying solely on the national grid is not a viable strategy for serious manufacturing. Instead, forward-thinking investors are implementing dedicated power systems designed for resilience and long-term cost control.

The Captive Power Plant (CPP): Your Private Energy Source

A captive power plant is a power generation facility built and operated for the exclusive use of an industrial or commercial consumer, providing independence from the public grid. While diesel generators have been a traditional choice, the most economically and environmentally sound solution today is a solar photovoltaic (PV) captive power plant.

A solar CPP involves installing a large-scale solar array, typically on the factory rooftop or adjacent land, to generate electricity during the day.

Key Advantages:

- Energy Security: It provides a reliable power source during daylight hours, directly insulating the factory from grid failures or voltage fluctuations.

- Cost Reduction: After the initial investment, the energy generated is effectively free, significantly lowering operational expenditures and hedging against rising electricity tariffs.

- Sustainability: A solar CPP enhances a company’s environmental credentials, a factor of growing importance for international markets and financing institutions.

Planning for a solar CPP should be integrated into the initial facility design, as it affects overall solar factory building requirements, including roof load capacity and land allocation.

Advanced Resilience: Integrating Battery Energy Storage Systems (BESS)

While a solar CPP solves the problem of daytime power instability, it doesn’t address nighttime operations or provide a seamless transition during an unexpected outage. This is where a Battery Energy Storage System (BESS) becomes essential.

A BESS is a large-scale rechargeable battery system that stores excess energy generated by the solar plant during the day. This stored energy can then be discharged whenever needed.

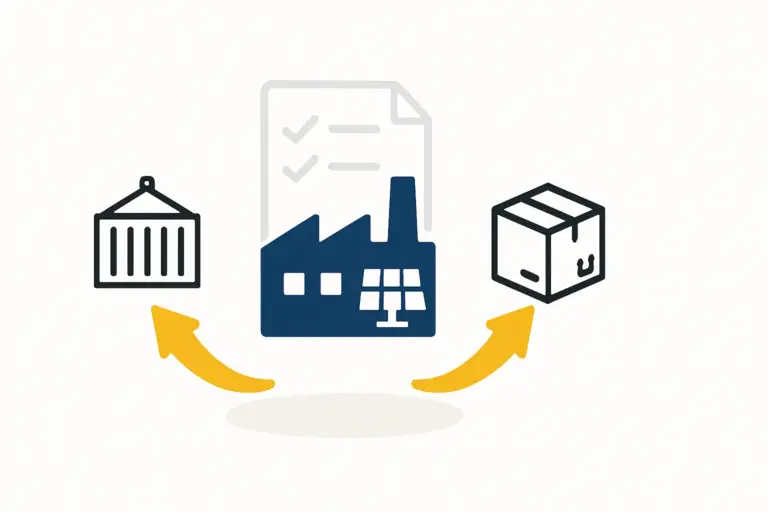

A solar-plus-BESS hybrid system creates the ultimate level of power security:

- Daytime Operation: The factory is powered directly by the solar panels, while any excess energy produced charges the BESS.

- Grid Outage (Day): The system instantly disconnects from the grid, and the solar panels continue to power the factory without any interruption.

- Nighttime Operation / Grid Outage (Night): The factory draws power from the fully charged BESS, allowing production to continue smoothly through the night.

This configuration provides a true Uninterruptible Power Supply (UPS) on an industrial scale, ensuring that critical machinery never loses power. Experience from J.v.G. turnkey projects shows that integrating a BESS from the outset is one of the most effective ways to de-risk manufacturing operations in regions with challenging grids.

Planning Your Factory’s Power Infrastructure

The decision to invest in a captive power solution is not an afterthought; it’s a strategic choice that belongs in the earliest stages of business planning. Factoring in the cost and design of a solar CPP and BESS is fundamental to creating a realistic budget and a resilient operational model.

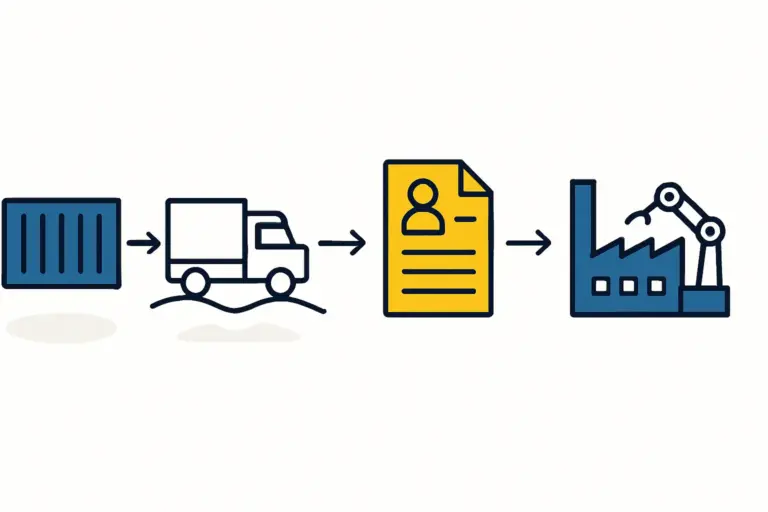

When planning a turnkey solar production line, the energy infrastructure is as critical as the manufacturing equipment itself. A comprehensive feasibility study is essential: it should model the factory’s load profile, analyze local solar data, and properly size the solar and battery systems to meet production targets without fail.

Frequently Asked Questions (FAQ)

What is the main difference between a captive power plant and a standard grid connection?

A standard grid connection means you are a customer of the national utility, subject to its reliability and pricing. A captive power plant is your own private power station, giving you direct control over your energy supply and costs.

How much space does a solar CPP require for a typical solar module factory?

The space requirement depends on the factory’s capacity. As a general rule, a 1 MW solar plant—often sufficient for a 50-100 MW module factory’s core needs—requires roughly one hectare (10,000 square meters) of land or roof space.

Is battery storage (BESS) an affordable solution for a new factory?

While BESS represents a significant capital investment, battery costs have fallen by over 85% in the last decade. When weighed against the costs of lost production, equipment damage, and diesel fuel, the return on investment for a BESS is highly compelling for critical manufacturing.

Can a factory run 100% on solar and batteries?

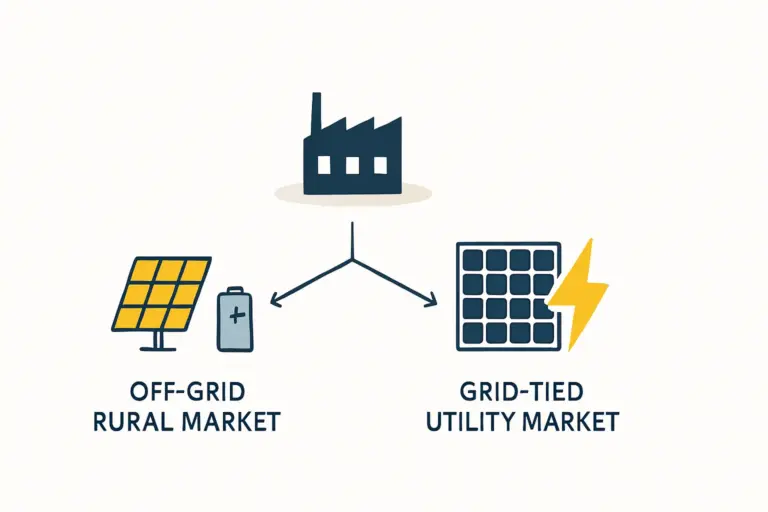

Yes, it is technically possible for a factory to operate completely ‘off-grid’ with a sufficiently large solar and battery system. However, a more common and cost-effective approach is to remain grid-connected, using the grid as a final backup and potentially selling excess solar power back to the utility where regulations permit.

What is the first step to ensure my factory has reliable power?

The first step is to conduct a professional energy demand analysis and feasibility study. This will determine your factory’s precise power requirements, assess the local solar resource, and provide a clear business case for investing in a captive power solution. Platforms like pvknowhow.com provide structured guidance to help investors navigate these initial planning stages.