The Netherlands, a global leader in agricultural technology, is home to over 9,000 hectares of advanced greenhouses. This vast expanse of glass is not just a horticultural powerhouse but also a significant, untapped opportunity for solar energy generation.

But realizing this potential requires more than standard, off-the-shelf solar modules. It calls for a specialized approach tailored to the unique demands of agriculture and architecture, creating a compelling business case for focused, high-value solar module manufacturing.

This article explores the niche but growing demand for custom solar modules in the Netherlands, specifically for agrivoltaics (horticulture) and Building-Integrated Photovoltaics (BIPV). It outlines why conventional manufacturing falls short and how a specialized production facility can serve this premium market.

The Limitation of Standard Solar Modules

Most of the world’s solar panels are mass-produced for one primary purpose: maximum energy generation on open land or conventional rooftops. They are standardized in size, opaque, and optimized for cost-per-watt at immense scale.

This model is fundamentally incompatible with specialized applications:

-

In Greenhouses: Standard modules block sunlight essential for plant growth, making them unsuitable for integration into greenhouse roofs.

-

On Buildings: Architects and developers require aesthetic flexibility. Standard blue or black panels often clash with building designs and cannot be customized in size, shape, or color to integrate into modern facades.

This incompatibility creates a market gap for modules designed not as an addition, but as an integral part of a structure’s function and design.

Understanding the Niche Markets: Agrivoltaics and BIPV

The demand for custom modules is driven by two powerful, converging trends: the need for sustainable agriculture and the push for energy-efficient buildings.

Agrivoltaics in Dutch Horticulture

Agrivoltaics is the practice of using the same area of land for both solar energy generation and agriculture. In the context of the Netherlands, this primarily means integrating semi-transparent solar modules into greenhouse structures.

The key is not just transparency but light spectrum management. Plants primarily use specific wavelengths of light for photosynthesis (known as Photosynthetically Active Radiation, or PAR). Specialized agrivoltaic modules are engineered to allow these vital wavelengths to pass through to the crops below while capturing other parts of the spectrum to generate electricity.

This dual-use approach enables operators to harvest both crops and energy from the same footprint, transforming a greenhouse from a simple agricultural structure into a power-generating asset. This creates an additional revenue stream and cuts the operator’s energy costs.

Building-Integrated Photovoltaics (BIPV) in Urban Environments

BIPV involves replacing traditional building materials with photovoltaic materials. Instead of placing panels on a roof or facade, the solar module is the facade, window, or roofing tile.

This market is experiencing significant growth, driven largely by regulations like the EU’s Energy Performance of Buildings Directive (EPBD). This directive mandates that new buildings be nearly zero-energy, pushing architects to incorporate renewable energy generation directly into their designs.

BIPV modules must meet architectural demands for:

-

Custom Sizes and Shapes: To fit non-standard facade elements.

-

Variable Transparency: For use in skylights and windows.

-

Aesthetic Finishes: Including a wide range of colors and textures.

Standard modules cannot meet these bespoke requirements, creating a clear opening for manufacturers who can.

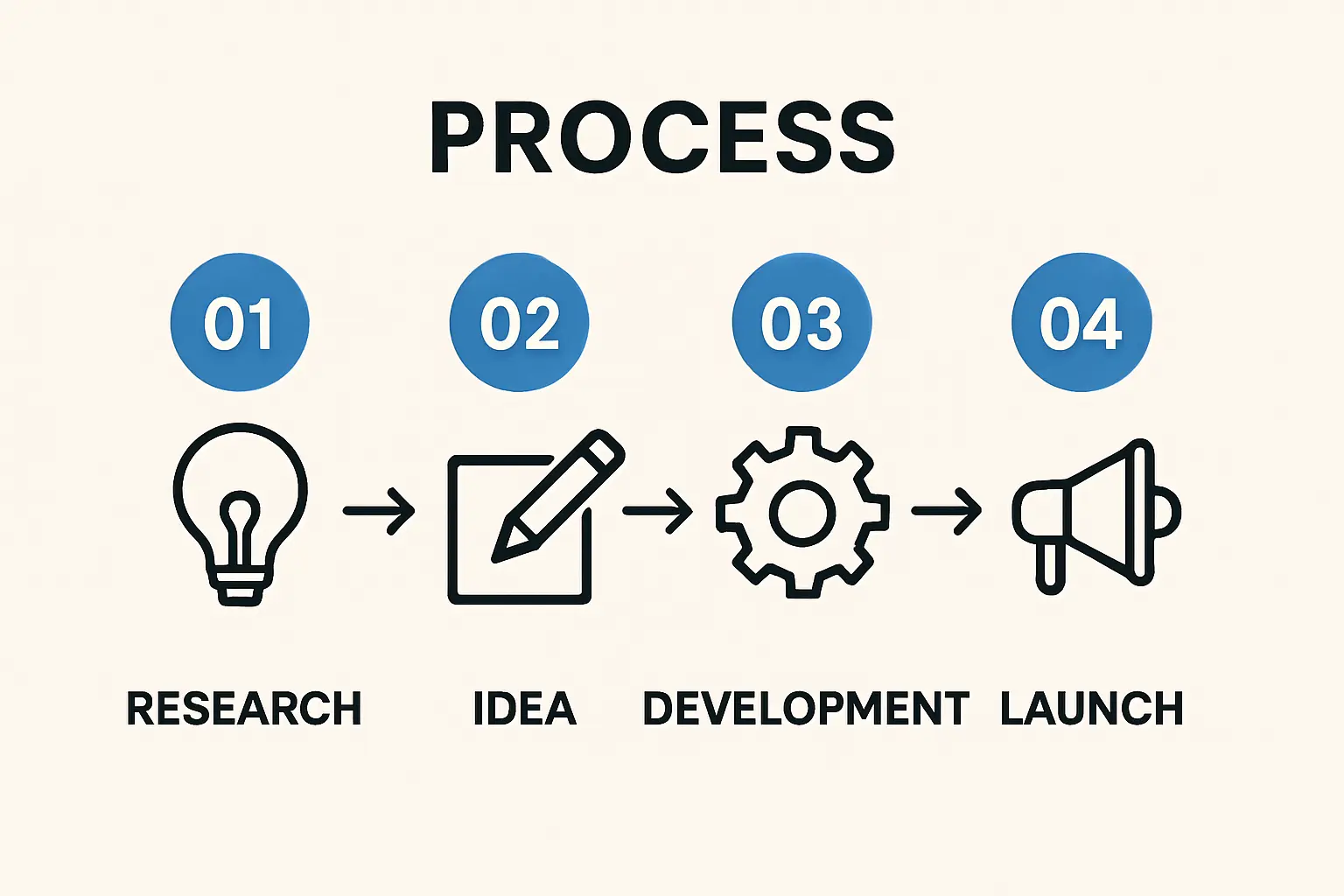

The Business Opportunity: Manufacturing for Specificity

The inability of mass-producers to serve these markets creates a distinct opportunity for new entrants. By focusing on customization and flexibility rather than pure volume, a specialized manufacturer can meet the high-value demands of the agrivoltaics and BIPV sectors.

The core of this business model is the ability to produce non-standard modules, which requires mastering production techniques that differ from conventional lines.

Key production capabilities include:

-

Controlled Cell Spacing: Varying the distance between solar cells within a module to control its transparency level.

-

Custom Lamination: Equipment that can handle different module sizes, shapes, and glass types.

-

Specialized Materials: The ability to work with colored backsheets, patterned glass, and other materials to achieve specific aesthetic outcomes.

For entrepreneurs considering how to enter the industry, understanding this distinction is crucial. The path to starting a solar panel manufacturing business in this niche is not about competing with large-scale Asian factories; it is about serving a local, specialized market that they cannot serve.

Economic and Strategic Advantages

This focused approach offers several benefits:

-

Higher Margins: Custom modules command a higher price-per-watt than standard modules, reflecting their added value and complexity.

-

Reduced Competition: The business operates in a niche with fewer, more specialized competitors.

-

Local Production Benefits: Manufacturing in or near Europe reduces logistics costs and shortens lead times for custom orders, while also appealing to clients who value a ‘Made in Europe’ quality standard.

Considerations for Establishing a Specialized Production Facility

Setting up a factory for specialized modules requires careful planning with an emphasis on flexibility.

Equipment and Technology

A specialized solar panel manufacturing line must be adaptable. While it includes core machines like laminators and cell stringers, its specifications must favor versatility over raw speed. For instance, the laminator must accommodate a wider range of module dimensions than a standard production line.

Factory and Operations

The layout of a solar panel manufacturing plant must be designed to manage a high-mix, low-volume production flow. This contrasts with a standard factory optimized for mass-producing identical products. Efficient material handling and process flow for custom orders are critical success factors. Based on J.v.G. Technology’s experience in turnkey projects, success in this niche is driven by process flexibility, not maximum throughput.

Investment and Profitability

While the initial solar panel manufacturing cost for a specialized line may be comparable to that of a small-scale standard line, the business model is fundamentally different. Profitability is derived from the premium pricing of custom products, not from economies of scale. A thorough business plan is essential to model the unique revenue and cost structure of this specialized venture.

Frequently Asked Questions (FAQ)

What is the primary difference between a standard and a specialized module factory?

A standard factory is built for high-volume, low-cost production of uniform products. In contrast, a specialized factory is designed for flexibility, capable of producing a wide variety of custom-sized, -shaped, and -colored modules in smaller batches.

How large is the potential market in the Netherlands and wider Europe?

The Dutch greenhouse market alone represents over 9,000 hectares. Combined with the BIPV market driven by EU-wide building regulations, the total addressable market for specialized modules is substantial and growing, measured in hundreds of megawatts annually.

Is prior solar industry experience necessary to start such a venture?

While helpful, it is not a prerequisite. Entrepreneurs with a strong background in manufacturing, business development, or construction can succeed with the right technical partners and guidance. The key is to understand the market’s needs and build a production process capable of meeting them.

What are the main technical challenges in producing transparent modules?

The primary challenges include ensuring long-term durability and weather sealing for custom shapes, managing the lamination process to avoid defects with non-standard materials, and consistently achieving the precise level of transparency and light spectrum transmission required by the client.

Can a specialized factory also produce standard modules?

Yes, a flexible line can typically be configured to produce standard modules. However, the factory’s cost structure is not optimized to compete with mass-producers on price. It is generally more profitable to focus on the high-value custom orders that define the business’s core market.

Conclusion: A Focused Strategy for a High-Value Market

The global solar market is often viewed as a commodity game dominated by scale. However, valuable opportunities exist for businesses that identify and serve specific, unmet needs. The demand for specialized solar modules for Dutch agrivoltaics and pan-European BIPV projects is a prime example.

For an entrepreneur or investor looking to enter the solar manufacturing sector, this niche offers a strategic entry point. It sidesteps direct competition with global giants and instead focuses on creating high-value, customized products for a market that is willing to pay a premium for solutions that work. By building a business around flexibility and technical expertise, a new manufacturer can establish a strong, defensible position in a growing segment of the renewable energy landscape.