An entrepreneur in New Zealand might look at the country’s goal of achieving 100% renewable electricity by 2030 and see a significant business opportunity. The idea of establishing a domestic solar panel manufacturing facility—creating ‘Made in New Zealand’ modules—is compelling.

However, this ambition quickly raises a critical question: who will operate the machinery? With a strong advanced manufacturing sector but no mature solar PV production industry, where would a company find qualified technicians and operators?

While this challenge might seem like a major obstacle, it is a manageable part of a well-structured business plan. The solution lies not in finding a pre-existing workforce, but in developing one. This article outlines a strategic approach to recruiting and training a skilled local labor force for a modern solar manufacturing line, turning a potential weakness into a source of competitive advantage.

Understanding the Roles on a Modern Production Line

Designing an effective training program begins with understanding the distinct roles required to operate a small- to medium-scale solar factory (e.g., 20–50 MW capacity). The workforce is not a monolithic group; it is made up of individuals with different skills and responsibilities.

Key Personnel Categories

Operators: These individuals form the core of the production team. They are responsible for running specific machines along the solar production line, such as the stringer, layup station, and laminator. Their work requires precision, attention to detail, and the ability to follow standardized procedures.

Technicians: This group brings a deeper level of technical expertise. They are responsible for machine setup, calibration, routine maintenance, and troubleshooting minor issues. They often have a background in electrical or mechanical trades.

Quality Control (QC) Inspectors: Positioned at critical points in the production process, QC inspectors ensure that materials and finished products meet stringent international standards. They operate testing equipment like sun simulators and EL testers.

Engineers and Management: This includes a production manager, a quality manager, and perhaps a process engineer. They oversee operations, analyze performance data, and implement improvements.

For a new venture, the immediate focus is on training the operators and technicians who will handle day-to-day manufacturing tasks.

A Phased Approach to Workforce Development

Building a capable team from the ground up is a methodical process. Research on skills transitions shows that workers from sectors like automotive assembly or electronics have highly transferable skills for PV production. The key is to leverage this existing aptitude through a structured training framework.

Phase 1: Recruitment Based on Aptitude, Not Experience

With experienced PV manufacturing personnel unlikely to be available locally in New Zealand, the recruitment strategy must shift. Instead of seeking specific solar experience, the focus should be on identifying candidates with core competencies:

Mechanical and Electrical Aptitude: Look for individuals from New Zealand’s robust vocational training system, such as graduates from Te Pūkenga polytechnics with qualifications in engineering or electronics.

Attention to Detail: Experience in any field that requires precision, such as electronics assembly or high-spec manufacturing, is a major asset.

Process-Oriented Mindset: Candidates who can consistently follow procedures and understand the importance of quality assurance are ideal.

Problem-Solving Skills: For technician roles, the ability to diagnose and resolve mechanical or electrical faults is crucial.

This approach widens the talent pool and taps into the existing strengths of the local industrial workforce.

Phase 2: Foundational Classroom Training

Once the initial team is hired, the first one to two weeks should be dedicated to foundational knowledge. This classroom training, held away from the production floor, covers the ‘why’ behind the ‘what.’

Core Topics Include:

PV Basics: How a solar cell works and how it is assembled into a module.

The Solar Module Manufacturing Process: A step-by-step overview from raw materials to the final product.

Material Handling: Proper procedures for handling delicate components like solar cells and glass.

Quality Standards: Introduction to IEC standards and the critical role of quality control in producing a bankable solar module.

Workplace Safety: Protocols specific to a manufacturing environment.

This phase ensures that every team member, regardless of their specific role, shares a common understanding of the product and the process.

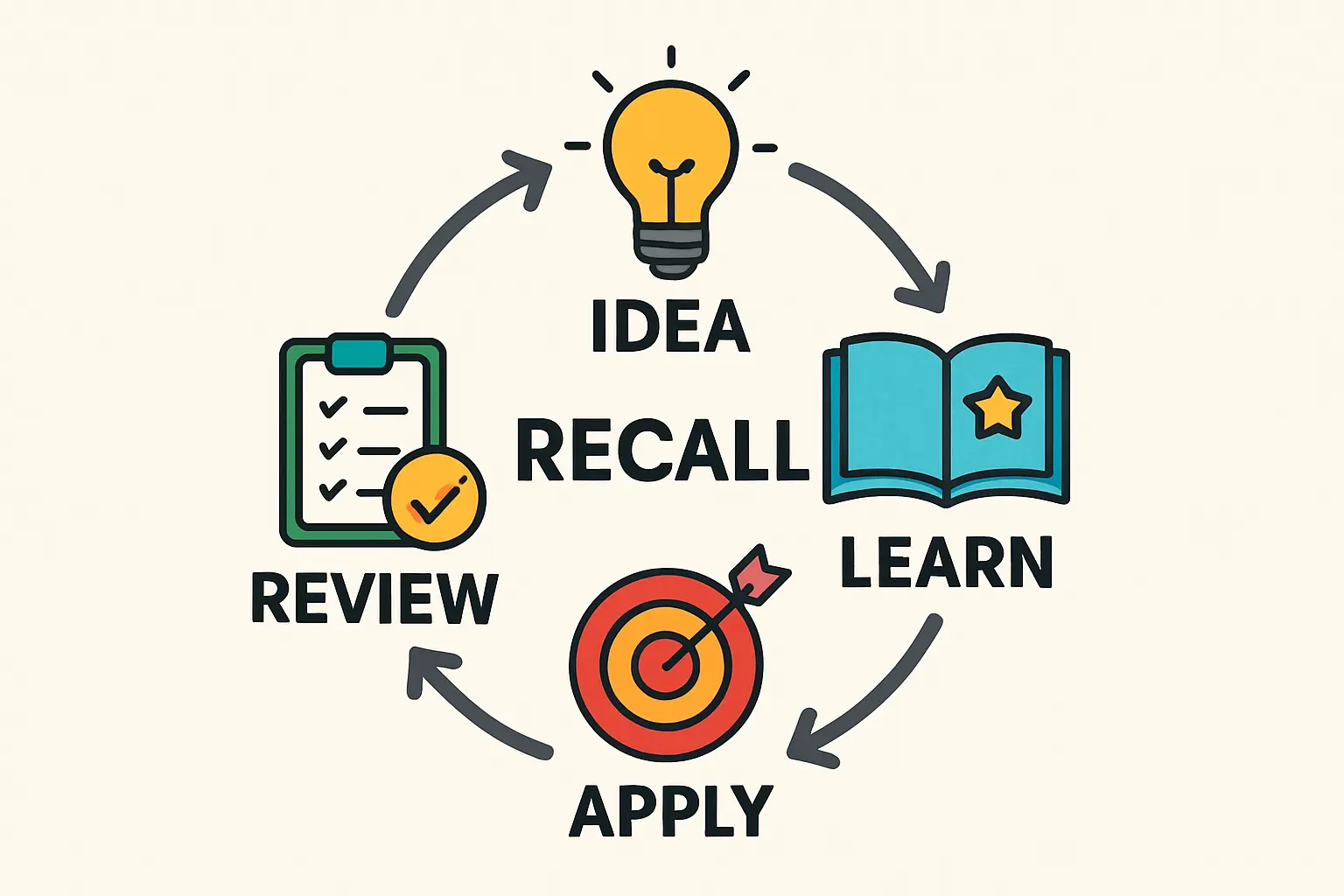

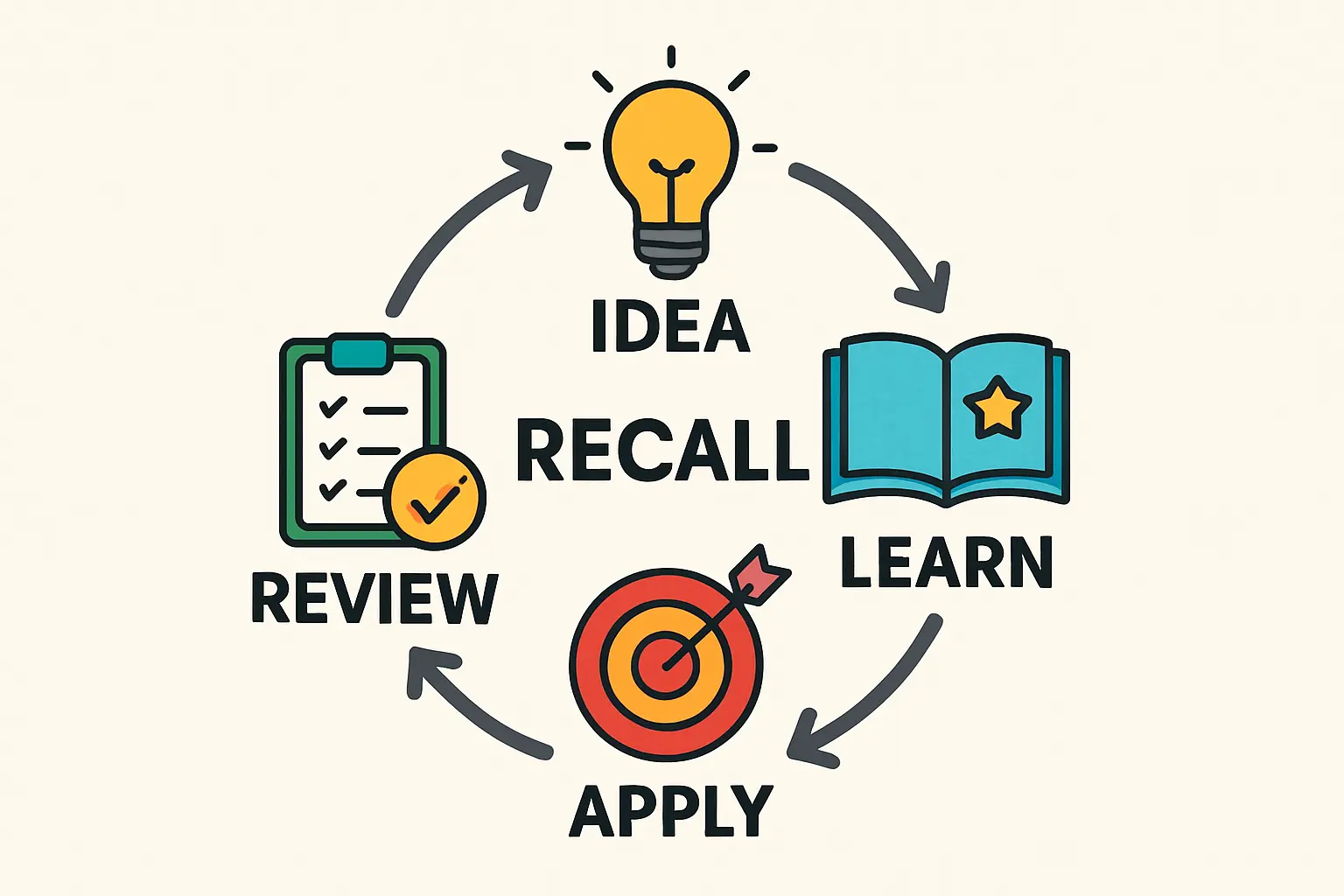

Phase 3: Structured On-the-Job Training (OJT)

This is the most critical phase, where theoretical knowledge translates into practical skill. OJT is not unstructured observation but a deliberate, supervised program.

Based on experience from J.v.G. turnkey projects, this phase is most effective when led by experienced engineers from the equipment supplier. These experts travel to the site during the commissioning of the production line and remain for several weeks to train the new team directly on the machines they will operate.

The OJT process involves:

-

Demonstration: The expert trainer operates the machine, explaining each step and safety precaution.

-

Supervised Practice: The local trainee operates the machine under the close supervision of the trainer, who provides real-time feedback and correction.

-

Independent Operation: The trainee runs the machine independently while the trainer observes, ensuring procedures are followed correctly and production targets are met.

This hands-on mentorship model is highly effective in building both competence and confidence.

Phase 4: Cultivating Self-Sufficiency and Specialization

Once the team can operate independently, the focus shifts from initial training to creating in-house experts.

Maintenance Training: Key technicians receive advanced training from equipment suppliers on preventive maintenance schedules, spare parts management, and more complex troubleshooting.

Cross-Training: Operators are trained on multiple machines to create flexibility in the workforce and cover absences.

Developing Team Leads: High-performing operators and technicians are identified and trained for future leadership roles, creating a path for career progression within the company.

A well-executed training program reduces reliance on external experts and lowers operational costs over the long term. The initial investment in a solar factory should always account for this crucial investment in its people.

The Business Case for Local Workforce Development

Investing in a comprehensive local training program offers more than operational readiness; it delivers tangible business benefits.

Reduced Costs: Training a local team is more cost-effective than relocating and housing expatriate specialists for an extended period.

Higher Quality: A team that understands the entire process and feels a sense of ownership is more likely to maintain high-quality standards.

Lower Employee Turnover: Providing clear training and career development paths fosters loyalty and reduces the high costs associated with employee churn.

Stronger Brand: A ‘Made in New Zealand’ solar panel, built by a skilled local workforce, creates a powerful marketing narrative that resonates with domestic customers and stakeholders. Government initiatives that have historically supported training in key industries may also provide a framework for backing such ventures.

Ultimately, a skilled and motivated workforce is not just a prerequisite for production—it is a core asset that drives the long-term success and sustainability of the manufacturing business.

Frequently Asked Questions (FAQ)

-

How many employees are needed to run a small solar factory?

For a 20–50 MW semi-automated line, a typical single shift requires approximately 25–30 employees. This includes operators, technicians, quality control personnel, and supervisory staff. -

What formal qualifications should we look for when hiring?

Focus on qualifications from vocational institutions in fields like electrical engineering, mechanical trades, or electronics technology. However, practical experience in any advanced manufacturing setting can be just as valuable as a formal degree. Aptitude and a willingness to learn are paramount. -

How long does the entire training process take?

The initial intensive training period, from classroom sessions through supervised on-the-job training, typically lasts four to six weeks. Continuous skill development and specialization, however, is an ongoing process. -

Can we start production without on-site expert trainers?

It is strongly discouraged. The guidance of an experienced engineer during the critical ramp-up phase is invaluable for establishing correct procedures, achieving target efficiency, and preventing costly mistakes with machinery and materials. -

Is it necessary to send local staff overseas for training?

While this can be an option for key personnel like the head of production, it’s generally more efficient and cost-effective to bring trainers to your facility. This allows the entire team to train simultaneously on the exact equipment they will be using.