Imagine a new solar module factory: state-of-the-art machinery, skilled technicians, and finished panels gleaming under the Nicaraguan sun. It’s a powerful vision. Yet long before the first module is assembled, a fundamental challenge must be met: how will millions of individual components—from delicate solar cells to large panes of glass—travel from manufacturing hubs in Asia to a factory floor in Central America?

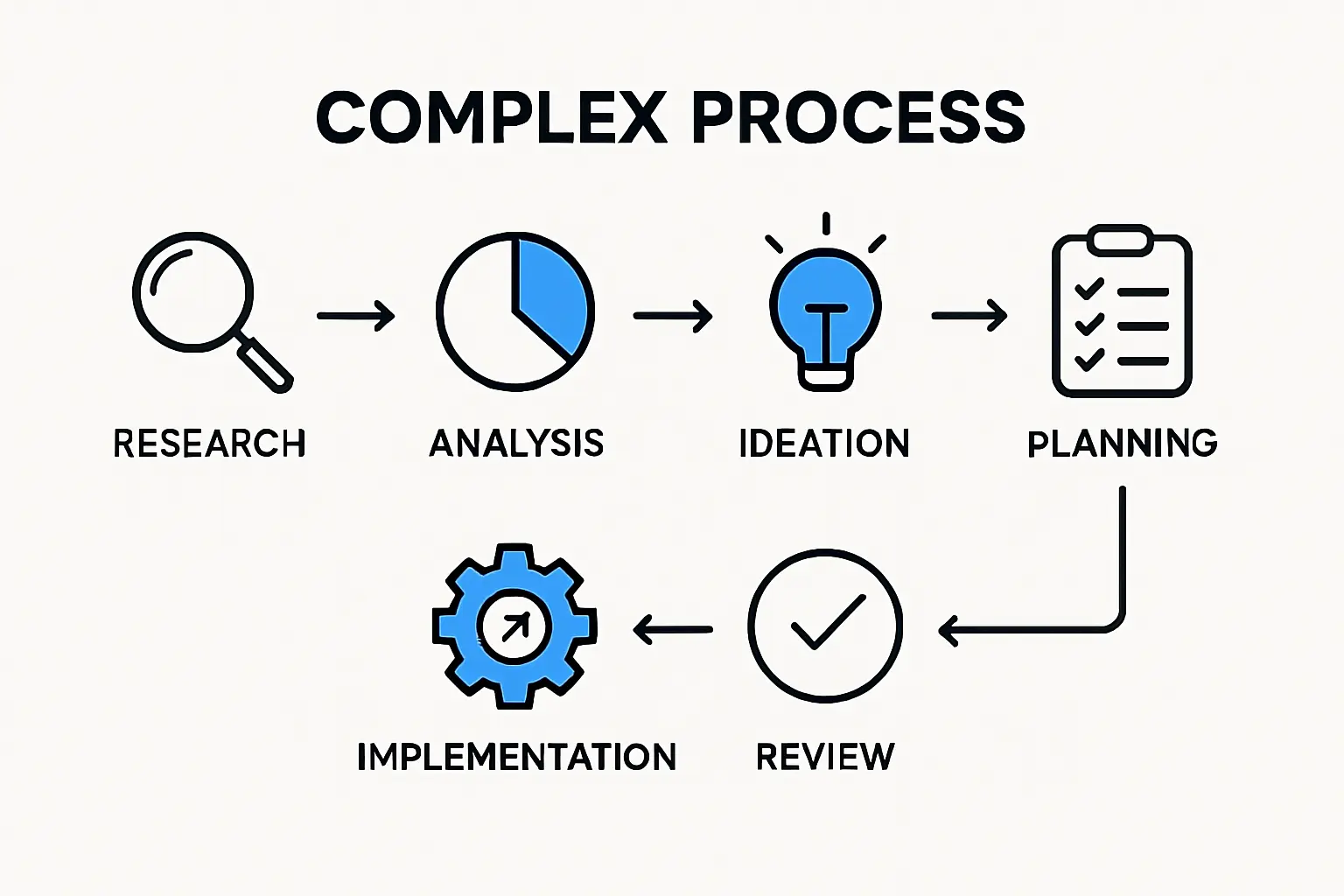

A solar manufacturing venture’s success often hinges not on its technology alone, but on mastering its supply chain. This guide provides a detailed analysis of the logistical framework for importing raw materials into Nicaragua, focusing on the country’s key ports, common challenges, and the strategic solutions required to build a resilient and efficient operation.

Nicaragua’s Strategic Position in the Global Supply Chain

Nicaragua offers a significant geographical advantage for international trade, with coastlines on both the Pacific Ocean and the Caribbean Sea. This dual-ocean access provides crucial entry points for goods arriving from different parts of the world—a key consideration for a global industry like solar manufacturing.

Port of Corinto: The Pacific Gateway

Located on the Pacific coast, the Port of Corinto is Nicaragua’s largest and most active seaport, handling the majority of the country’s containerized cargo, bulk goods, and liquids. For a solar factory, Corinto is the most logical entry point for materials sourced from the industry’s manufacturing centers in Asia, such as China, Taiwan, South Korea, and Malaysia. Its infrastructure is the best equipped in the country to handle the large container ships that cross the Pacific.

Port of El Rama: The Caribbean Connection

Situated on the Escondido River, the Port of El Rama serves as the main gateway to the Caribbean coast, connecting by waterway to the deep-water port in Bluefields. While smaller than Corinto, it provides a strategic alternative for shipments originating from Europe or the Americas. Depending on specific shipping routes and costs, it offers a viable option for certain materials or equipment.

Essential Raw Materials and Their Primary Sources

A solar module assembly line depends on a steady flow of imported, high-technology components. Understanding the key components of a solar module is the first step in building a robust supply chain. The most critical imported materials include:

- Solar Cells: The core technological component that converts sunlight into electricity.

- EVA (Ethylene Vinyl Acetate) Film: An encapsulant used to laminate and protect the solar cells.

- Tempered Glass: The durable front layer that protects the module from the elements.

- Backsheets: The protective rear layer of the module.

- Junction Boxes: The electrical enclosure on the back of the panel.

Given the state of the global solar industry, the vast majority of these materials are sourced from specialized manufacturers in Asia. This reliance makes mastering the Pacific shipping route and operations at the Port of Corinto a critical priority for any new solar enterprise in Nicaragua.

Navigating the Primary Logistical Challenges

Importing high-value, sensitive goods into any emerging market presents a unique set of hurdles. Entrepreneurs must anticipate and plan for these challenges to avoid costly delays that can disrupt production timelines and profitability.

Customs and Bureaucracy

Nicaraguan customs procedures can be complex and are often a significant bottleneck. Incomplete or inaccurate paperwork, misclassification of goods, or unfamiliarity with local regulations can lead to shipments being held for extended periods. Experience from J.v.G. Technology GmbH turnkey projects shows that improper documentation is a leading cause of preventable and costly delays.

Port Operations and Infrastructure

While Corinto is the country’s main port, it can experience periods of congestion that slow down unloading times. Furthermore, the quality of inland infrastructure, such as roads and bridges, can vary significantly once cargo leaves the main transport corridors. Planners must factor this into the final leg of the journey from the port to the factory.

Security and Cargo Integrity

Ensuring the security of high-value items like solar cells and other components from port to factory is paramount. Using sealed, containerized shipping is standard practice, as it provides a high degree of protection against both damage and theft throughout the journey.

Local Supplier Landscape

The lack of specialized local suppliers for core solar components means a Nicaraguan factory will be almost entirely dependent on imports. This reality makes meticulous supply chain management essential, as there are few local alternatives to fall back on if a shipment is delayed.

Strategic Solutions for a Resilient Supply Chain

A proactive, well-planned approach can effectively mitigate logistical risks. The following strategies are essential for establishing a smooth and predictable flow of materials.

Partnering with Local Expertise

Engaging a reputable and experienced local customs broker and freight forwarder is perhaps the single most critical investment in the supply chain. These partners bring invaluable knowledge of Nicaraguan customs law, port procedures, and inland transportation networks. They can manage documentation, navigate bureaucracy, and troubleshoot issues on the ground, saving the business owner significant time and resources.

Planning and Timelines

International shipping is subject to unpredictable events, from weather disruptions to port congestion. A prudent business plan will incorporate a logistical buffer of four to six weeks into its timelines. This buffer absorbs potential delays without derailing the project schedule and is a crucial part of keeping the solar module manufacturing process on track.

Shipment Consolidation and Nearshoring

To optimize costs, many entrepreneurs consolidate shipments from various Asian suppliers into a single container or bill of lading, simplifying both shipping and customs clearance. It is also wise to explore nearshoring possibilities for less specialized, heavier components. For instance, sourcing aluminum frames from established manufacturers in Mexico or the United States can diversify the supply chain and potentially reduce shipping costs and lead times.

Financial and Regulatory Considerations

A clear understanding of the full cost structure and the local regulatory environment is fundamental for accurate financial forecasting.

Understanding the Cost Structure

The final landed cost of raw materials goes far beyond the supplier’s price. Key components include:

- Freight and Insurance: The cost of transporting goods from the country of origin to the Nicaraguan port.

- Customs Duties and Taxes: Tariffs and value-added taxes levied on imported goods.

- Port Handling Fees: Charges for unloading, storage, and processing at the port.

- Inland Transportation: The cost of moving containers from the port to the factory.

Leveraging Government Incentives

Nicaragua’s Law No. 532, the ‘Law for the Promotion of Electricity Generation with Renewable Sources,’ offers significant incentives, including potential tax exemptions on the importation of equipment and materials for renewable energy projects. Investors should conduct thorough due diligence with local legal counsel to confirm eligibility for these benefits, a step often included in the comprehensive business planning phase supported by pvknowhow.com.

Frequently Asked Questions (FAQ)

Which Nicaraguan port is best for imports from China?

The Port of Corinto on the Pacific coast is the most direct and best-equipped port for handling containerized shipments from China and other Asian manufacturing hubs.

How long does customs clearance typically take?

This can vary widely depending on the accuracy of the documentation and port congestion. While it can sometimes be completed in a few days, it is wise to plan for a week or more. An experienced customs broker is essential for expediting this process.

Are there import taxes on solar components in Nicaragua?

Generally, imports are subject to duties and taxes. However, under Law No. 532, projects related to renewable energy may qualify for significant exemptions. A formal application and approval process are typically required.

Is it better to source everything from one country?

While consolidating shipments of core components from a primary region like Asia is efficient, diversifying the supply chain by nearshoring other materials (like aluminum frames from Mexico) can reduce dependency on a single region and mitigate logistical risks.

Conclusion: Building a Foundation for Success

Nicaragua’s strategic location presents a compelling opportunity for establishing a solar module manufacturing facility to serve domestic and regional markets. This advantage, however, can only be realized through a meticulously planned and professionally managed supply chain.

Success in this venture isn’t about becoming a logistics expert overnight. It’s about recognizing the complexities involved and building a robust network of experienced partners—from suppliers and freight forwarders to customs brokers. By anticipating challenges, building in contingencies, and leveraging local expertise, an entrepreneur can create a reliable flow of materials that serves as the bedrock of a profitable and sustainable manufacturing operation. A clear understanding of this logistical framework is the first step toward building a comprehensive and successful business plan.