Imagine the final preparations for your new solar module factory in Niamey. Millions have been invested in state-of-the-art equipment, and the first production run is scheduled. Suddenly, the power cuts out. The notoriously unreliable grid remains down for the next eight hours. Production halts before it even begins.

This scenario isn’t just a remote possibility—it’s a critical operational risk for any industrial venture in regions with developing power infrastructure. For an entrepreneur entering the solar manufacturing sector, ensuring a stable, uninterrupted power supply is a foundational challenge. This article explores why a dedicated hybrid power system is not merely an expense but a strategic investment in operational certainty and long-term profitability, using Niger as a practical case study.

The Paradox of Power: Why a Solar Factory Needs Its Own Reliable Energy

While a solar factory’s end product generates electricity, the manufacturing process itself is highly energy-intensive. Operating in a region with an unstable power grid presents a significant business paradox.

According to World Bank data, the electricity access rate in Sub-Saharan Africa stands at approximately 48.6%. In Niger, this figure plummets to just 19.3%, with rural access at a mere 8.9%. This translates to frequent and often prolonged power outages that can severely disrupt industrial operations.

For a business, this instability leads to:

-

Production Downtime: Every hour the grid is down is an hour of lost production and revenue. Studies show that unreliable power can cost businesses in the region between 2% and 4% of their annual revenue.

-

Material Waste: Many processes in solar module manufacturing, such as lamination and curing, are time- and temperature-sensitive. An unexpected power loss during these stages can ruin entire batches of materials, directly slashing production yields.

-

Equipment Damage: Sudden power outages and subsequent surges when the grid returns can damage sensitive and expensive manufacturing equipment, leading to costly repairs and extended downtime.

Relying on the national grid alone creates an unacceptable level of operational risk, making energy independence a critical component when starting a solar panel factory.

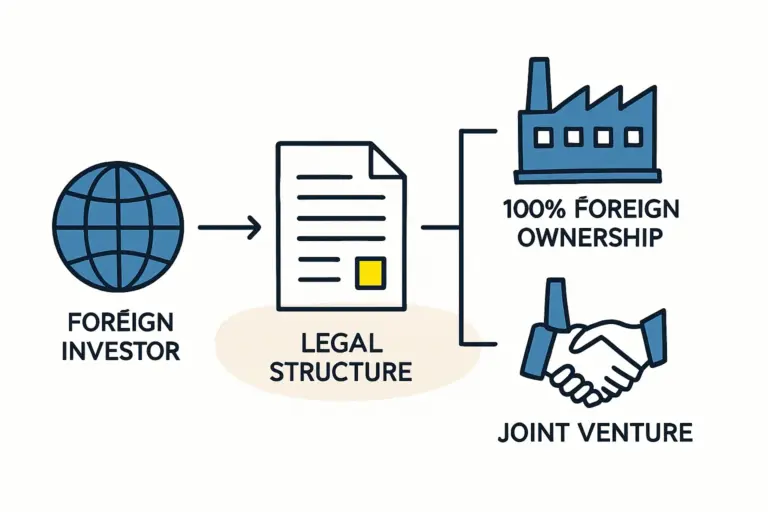

An Overview of Hybrid Power Systems for Industrial Use

A hybrid power system integrates two or more energy sources to deliver a continuous and reliable supply of electricity. For an industrial application like a solar factory in Niger, a typical configuration includes solar PV, a Battery Energy Storage System (BESS), and a diesel generator, often working in concert with the local grid when it is available.

Each component serves a specific purpose:

-

Solar PV Array: The solar PV array is the primary power source. Given Niger’s high solar irradiation levels (averaging 6.0-6.5 kWh/m²/day), a correctly sized solar array can power the entire factory during daylight hours while also charging the battery system.

-

Battery Energy Storage System (BESS): The BESS stores excess energy generated by the solar panels. It provides instant, seamless power during grid outages, at night, or during moments of peak demand, ensuring production continuity.

-

Diesel Generator: This acts as a final layer of backup. It is designed to run during extended periods of low solar generation (e.g., several consecutive cloudy days) or when the battery system is depleted, guaranteeing 24/7 operational capability.

-

Grid Connection: When the national grid is stable, the factory can draw power from it. An intelligent power management system determines the most cost-effective source of energy at any given moment.

This multi-layered approach creates a ‘captive power plant’ dedicated to the factory, transforming the energy supply from a variable risk into a controlled operational parameter.

The Strategic Business Case for a Captive Power Plant

Viewing an on-site power system solely as a capital expense is a common mistake. It should be analyzed as a strategic investment that directly protects revenue and enhances profitability over the long term.

From Unpredictable Cost to Controlled Asset

Relying on a combination of an unstable grid and diesel generators results in volatile and unpredictable energy costs. Diesel prices fluctuate, and grid tariffs can change. A solar hybrid system, by contrast, provides a predictable cost of energy for 25 years or more. The result is more accurate financial forecasting and stable production costing—a significant competitive advantage.

Quantifying the Return on Investment (ROI)

While the initial investment is higher than simply connecting to the grid, the long-term economics are compelling. The Levelized Cost of Energy (LCOE)—the total cost of the system divided by its total energy output over its lifetime—for a solar-plus-storage system is often significantly lower than the cost of running diesel generators. Savings on fuel, generator maintenance, and lost production due to outages drive a strong return on investment.

This investment must be factored into the overall financial plan, which is a key part of understanding solar panel manufacturing costs.

Key Components of a Resilient Factory Power System

A successful captive power plant relies on the quality and proper integration of its core components.

Solar PV Array: The Primary Energy Generator

The solar array is the engine of the power plant. The system must be designed to meet the factory’s peak daytime load and generate surplus energy to charge the batteries. In a high-irradiation environment like Niger, the array delivers a highly reliable and cost-effective source of daytime power.

Battery Energy Storage System (BESS): The Heart of Stability

The BESS is what makes uninterrupted, 24/7 operation possible. It acts as a buffer, absorbing excess solar energy and discharging it precisely when needed. Modern industrial-grade batteries provide the instantaneous response required to prevent even a millisecond of power disruption to sensitive manufacturing machinery.

Diesel Generator: The Ultimate Safeguard

In a hybrid system, the role of the diesel generator fundamentally changes. It shifts from being a primary backup to a tertiary, or emergency, safeguard. This drastically reduces its run hours, generating significant savings in fuel and maintenance costs and extending its operational lifespan.

Intelligent Power Management System (PMS)

The PMS is the brain of the entire operation. This control system continuously monitors the factory’s energy demand, solar generation, battery charge level, and grid status. It automatically optimizes the flow of energy from the most economical source, ensuring seamless operation without manual intervention.

Practical Considerations for Implementation

Deploying a successful hybrid power system requires careful planning that extends beyond selecting hardware.

-

System Sizing: The system must be meticulously engineered based on the factory’s detailed load profile. This involves analyzing the power consumption of all the essential machinery for solar module production, from stringers and laminators to testing equipment. An undersized system will fail to provide adequate reliability, while an oversized one represents an unnecessary capital expense.

-

Local Integration: Partnering with experienced engineers who understand both the technology and the local operating conditions is critical. Experience from J.v.G. Technology turnkey projects shows that local logistics, technical skill availability, and environmental factors like heat and dust must be incorporated into the design.

-

Long-Term Maintenance: A plan for ongoing operation and maintenance (O&M) is essential to ensure the system performs optimally over its multi-decade lifespan.

These considerations are an integral part of planning for complete turnkey solar manufacturing lines, where all aspects of the operation are designed to work in harmony.

Conclusion: Securing Production is Securing Your Investment

For any entrepreneur planning a solar factory in Niger or a similar market, the question is not whether to invest in a reliable power source, but how to design the most effective one. A well-engineered solar hybrid power system is the answer. It transforms the critical variable of energy supply from an external risk into an internal, controllable asset.

This investment insulates the manufacturing operation from grid instability, protects expensive equipment, eliminates production losses, and provides long-term energy cost stability. It is a foundational pillar for building a resilient, profitable, and successful solar module manufacturing business.

Frequently Asked Questions (FAQ)

What is the typical power requirement for a small-scale solar factory?

A small-to-medium scale factory with a production capacity of 20-50 MW per year typically has a peak power demand in the range of 250 kW to 600 kW. The exact figure depends on the specific machinery and level of automation.

Can the factory run on solar power alone?

During daylight hours with sufficient sun, yes. However, for 24/7 operations, which are common in manufacturing to maximize output, a battery storage system is essential to provide power at night, and a backup generator is needed for periods of extended bad weather.

How does a hybrid system compare to relying solely on diesel generators?

A hybrid system has a higher upfront cost but significantly lower operating costs. It can reduce diesel consumption by 80-90%, resulting in massive fuel savings, less noise, lower emissions, and reduced maintenance. A diesel-only solution exposes the business to volatile fuel prices and high O&M expenses.

What is the typical payback period for a captive solar-plus-storage system?

The payback period depends on local factors such as the cost of grid electricity and diesel fuel. In many African markets, the payback period for an industrial solar hybrid system can range from 4 to 7 years, after which the solar energy is virtually free.

Is it possible to sell excess solar power back to the grid in Niger?

Policies for selling power back to the utility (net-metering or feed-in tariffs) vary by country and are subject to change. While technically possible, the business case for a captive power plant should be based on self-consumption and operational reliability first. Any potential revenue from exporting power should be considered an additional benefit, and a thorough review of current local regulations is essential.