An investor considering Niger encounters two striking realities. First, a nation with one of the lowest electricity access rates in the world, where, according to the World Bank, less than 10% of the population is connected to the grid. Second, a country on a continent with the world’s youngest population—a vast reservoir of human potential.

The opportunity to connect this demographic dividend with the urgent need for energy is the foundation of a modern industrial strategy.

For an entrepreneur planning to establish a solar module factory in this environment, the most critical question is not about technology, but about people. How do you build a technically proficient workforce where none existed before? This article outlines a structured, practical model for recruiting, training, and developing local talent to operate a modern solar module assembly facility in Niger, transforming a perceived challenge into a strategic advantage.

The Strategic Importance of Human Capital in Solar Manufacturing

According to the International Renewable Energy Agency (IRENA), the solar PV sector is the world’s largest renewable energy employer, accounting for 4.3 million jobs globally. While installation projects create employment, localizing the manufacturing process creates higher-skilled, more stable, and more valuable jobs.

This approach builds a foundation for industrial self-sufficiency and captures a larger portion of the value chain within the country.

Africa’s demographic profile, with a median age of just 19.7, presents a unique opportunity. A solar factory in Niger can become a center for technical skill development, offering meaningful careers to a generation eager for a foothold in the future. The goal is not merely to fill positions but to cultivate a skilled workforce that can drive the industry forward for decades.

A Phased Approach to Recruitment and Selection

In a nascent market, seeking experienced solar technicians is impractical. The recruitment strategy must instead focus on identifying individuals with the right aptitude and motivation.

Phase 1: Partnering with Local Institutions

The process begins with building relationships with vocational training centers, technical high schools, and universities in cities like Niamey. The objective is not to find ready-made experts but to identify a pool of candidates who have a foundational grasp of technical principles and a demonstrated ability to learn. Collaborating with these institutions helps build trust within the community and creates a sustainable pipeline of future talent.

Phase 2: Aptitude-Based Screening

Candidates are evaluated through a series of practical, hands-on tests designed to assess core competencies rather than existing knowledge. These assessments may include:

- Manual Dexterity Tests: Assembling small, simple components to gauge fine motor skills.

- Attention to Detail Exercises: Identifying minor defects in sample materials or images.

- Instruction-Following Drills: Executing a multi-step task based on clear, visual diagrams.

This approach bases selection on an individual’s potential to succeed in a structured manufacturing environment.

Phase 3: The Interview Process

The final stage focuses on understanding a candidate’s mindset. Key areas to explore include their motivation for joining the renewable energy sector, their long-term career aspirations, and their capacity for teamwork. A committed and motivated team is the most valuable asset in the early stages of operation.

Designing an Effective In-House Training Program

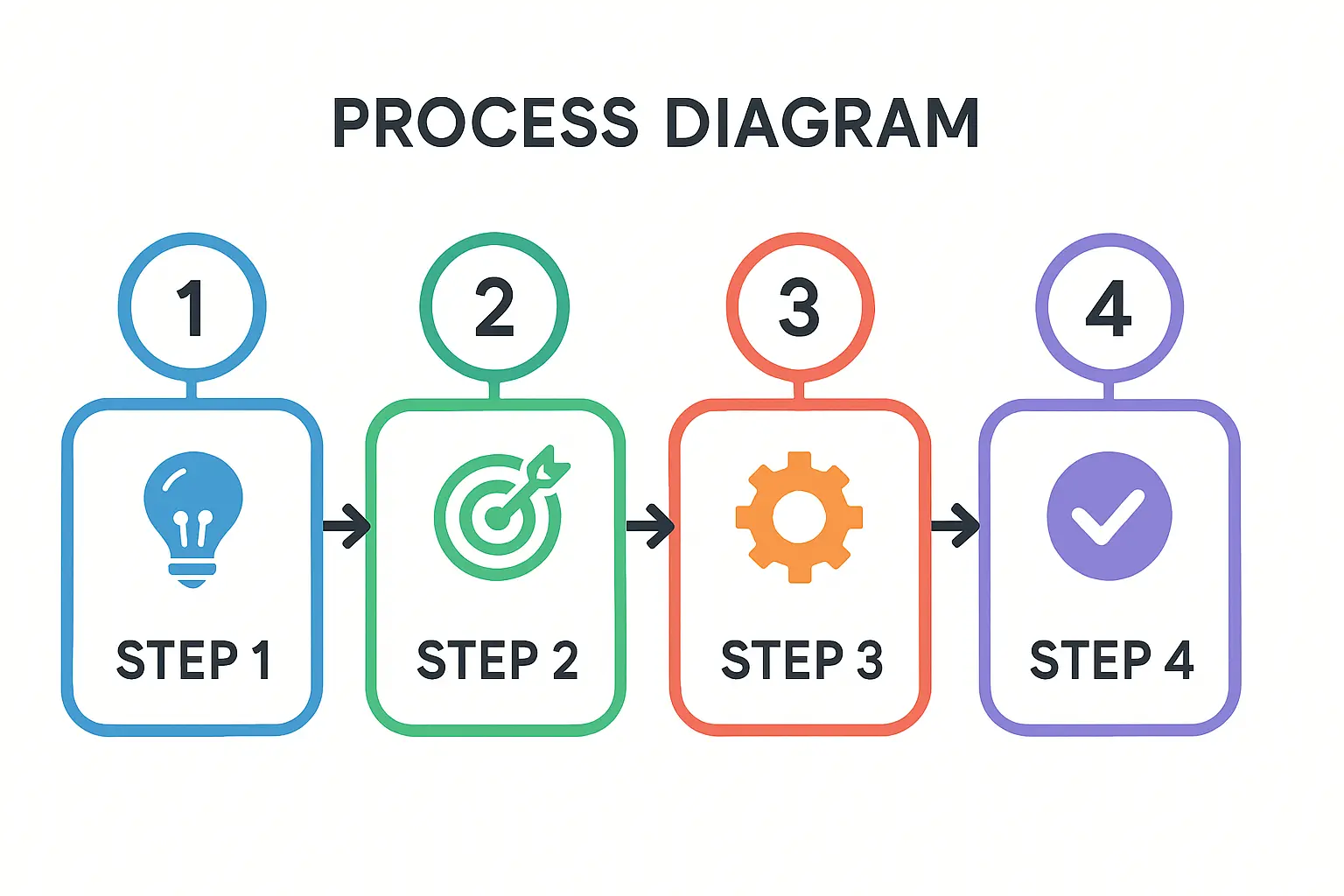

Based on data from J.v.G. turnkey projects, a non-technical workforce can achieve operational readiness through a structured 12-week program. This program is designed to build skills sequentially, moving from basic theory to confidently operating a complete solar module assembly line.

Stage 1: Foundational Knowledge (Weeks 1-3)

This classroom-based stage covers the essential theoretical background. The curriculum is delivered using simple language and extensive visual aids to ensure clarity.

- PV Basics: How a solar cell works and how modules generate electricity.

- Production Process: An overview of each step, from cell stringing to final lamination.

- Quality Standards: The importance of precision and what constitutes a high-quality solar module.

- Workplace Safety: Comprehensive training on safety protocols for a factory environment.

Stage 2: Simulated Production Environment (Weeks 4-8)

Trainees move to a dedicated training area equipped with offline machinery or simulators. Here, they practice each production step using non-critical materials. This hands-on phase allows them to build muscle memory and familiarity with the equipment without the pressure of live production. The focus is on mastering the process for each machine, from the stringer to the laminator and framer.

Stage 3: On-the-Job Mentorship (Weeks 9-12)

In the final stage, trainees are integrated into the live production floor under the direct supervision of experienced technicians—often provided by the equipment supplier. They begin with simpler tasks and gradually assume more responsibility as their confidence and competence grow. This mentorship model is critical for effective knowledge transfer and for learning to handle real-world production variables.

Key Roles and Skill Progression

A typical 50 MW semi-automated assembly line requires a production staff of 30 to 40 people. The primary roles filled through this training program include:

- Machine Operators: Responsible for the day-to-day operation of specific equipment like stringers, lay-up stations, and laminators.

- Quality Control Inspectors: Responsible for visual and electronic inspection at critical points in the production process to ensure standards are met.

- Maintenance Technicians: Technicians with a stronger mechanical or electrical aptitude who are trained to perform routine maintenance and basic troubleshooting.

A clear path for career advancement is essential for staff retention. A machine operator can progress to become a line supervisor, and a quality inspector could eventually be trained as a quality assurance manager. The initial investment for a solar factory must budget for this continuous development.

Overcoming Common Challenges

Entrepreneurs should anticipate and plan for several common hurdles:

- Language and Technical Barriers: Technical documentation is often in English or German. Translating key materials and using a visual-first approach in training is vital.

- Cultural Adaptation: International best practices in manufacturing must be thoughtfully integrated with local work culture to create an efficient and respectful environment.

- Staff Retention: The best way to retain skilled employees is to offer competitive compensation, a safe working environment, and tangible opportunities for career growth.

Comprehensive turnkey factory solutions often include a structured training and knowledge-transfer component to address these challenges from the outset.

Frequently Asked Questions (FAQ)

What is the ideal educational background for trainees?

A secondary school diploma or a certificate from a vocational or technical school is generally sufficient. More important than formal education is a candidate’s aptitude for technical work, attention to detail, and willingness to learn.

How many employees are needed to start a 50 MW factory?

For a semi-automated line, a production team of 30–40 people, working in shifts, is a typical starting point. This includes operators, quality control staff, and maintenance personnel.

Can the entire workforce be sourced locally?

Yes, all production and operational roles can and should be filled by a local workforce. For highly specialized senior roles, such as Head of Engineering or Plant Manager, it may be necessary to hire an experienced expatriate for the first one to two years to oversee operations and mentor their local successor.

How much does a comprehensive training program cost?

The cost depends on the program’s duration, the number of external trainers required, and the materials used. This cost should be seen not as an expense but as a core part of the initial capital investment, essential for mitigating operational risk and ensuring long-term success.

Conclusion: Building a Sustainable Local Industry

Establishing a solar module factory in Niger is an investment in both physical and human capital. The technology is attainable, but a well-trained, motivated local workforce is the ultimate key to long-term success. By implementing a structured recruitment and training model focused on local potential, an entrepreneur can build not just a factory, but a cornerstone for a new, sustainable industry that empowers its people and powers its future.

For business professionals exploring this venture, the next step is to integrate a detailed human resources and training strategy into a comprehensive business plan. Developing your team should be given the same priority as procuring your technology.