Disclaimer: This case study represents a composite example derived from real-world

consulting work by J.v.G. Technology GmbH in solar module production and factory optimization. All data points are realistic but simplified for clarity and educational purposes.

For many business leaders in Nigeria, the daily operational report reads like a battle plan against uncertainty. With grid power available less than 50% of the time, the hum of a diesel generator is the constant, costly soundtrack of commerce.

As diesel prices climb past N1,700 per litre, this reliance has shifted from a necessary expense to a critical vulnerability. This reality, however, presents a significant strategic opportunity for entrepreneurs looking to enter a market at its tipping point: local solar module manufacturing.

This article outlines a practical investment blueprint for establishing a 20 MW solar module assembly facility in Lagos. It details a pathway to launch within 12 months with an initial investment under $5 million, specifically targeting the commercial and industrial (C&I) sector. The plan relies on specialized technology designed for regional conditions and experienced guidance to navigate the complexities of a new venture.

The Nigerian C&I Market: A Tipping Point for Solar

Nigeria’s C&I sector—which includes factories, commercial buildings, and agricultural enterprises—consumes over 70% of the nation’s grid-supplied electricity. Yet, an estimated 62% of these businesses rely on expensive, self-generated power to maintain operations. The result is a powerful, built-in demand for a more reliable and cost-effective energy source.

The economic case is compelling:

- Operational Stability: Unreliable power disrupts production schedules, damages sensitive equipment, and creates significant business risk. Solar offers energy independence.

- Cost Reduction: The escalating cost of diesel makes the return on investment for solar solutions increasingly attractive. For many businesses, the payback period is now shorter than ever.

- Government Focus: Recognizing the economic drag of the energy crisis, the Nigerian government is actively promoting local manufacturing through incentives and policy support, fostering a favorable environment for new entrants.

This convergence of urgent need and supportive policy creates a prime market for locally produced solar modules tailored to the specific demands of the C&I sector.

Why Local Assembly Offers a Strategic Advantage

While importing solar modules is an option, establishing a local assembly plant provides distinct competitive advantages. The Renewable Energy Association of Nigeria (REAN) has strongly advocated for policies that favour local producers, leading to tangible benefits for entrepreneurs who invest in domestic manufacturing.

Key Advantages of Local Production:

- Cost Efficiency: Assembling modules locally mitigates the impact of import duties on finished solar panels, creating a significant cost advantage over imported alternatives.

- Government Incentives: New manufacturing ventures may qualify for “Pioneer Status,” a government incentive providing a tax holiday for up to five years. This can dramatically improve the financial viability of a new plant.

- Supply Chain Control: Local assembly reduces dependency on complex international logistics, shortens lead times for C&I customers, and allows for greater quality control.

By manufacturing in-country, a business becomes not just a supplier but a key contributor to Nigeria’s industrial and energy independence goals.

A Practical Blueprint: The 20 MW Lagos Starter Plant

Launching a solar manufacturing facility requires a clear, structured plan. The following blueprint outlines a viable model for a 20 MW assembly line in Lagos, designed for rapid deployment and focused market entry.

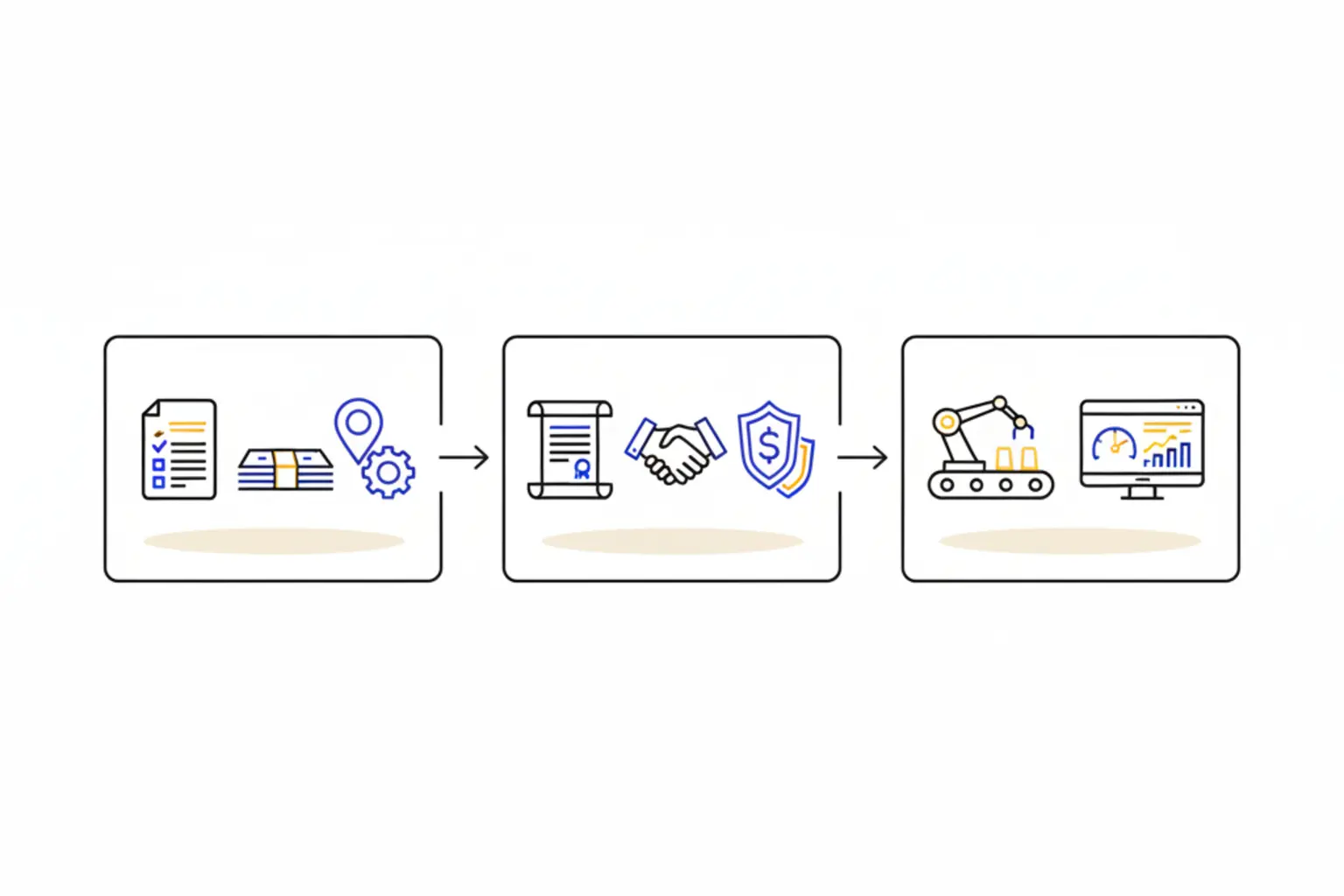

1. Investment & Financing Strategy

The initial investment for a facility of this scale is typically under $5 million. This capital covers manufacturing equipment, initial raw materials, setup, and operational runway.

For Nigerian entrepreneurs, a key financial partner is the Bank of Industry (BOI). The BOI actively supports industrialization with financing programs for manufacturing projects that align with national development goals. Securing sub-$5M financing through such institutions is achievable with a well-structured business plan.

2. Location: The Lekki Free Trade Zone Advantage

As Nigeria’s commercial heart, Lagos is the logical hub for this venture. The Lekki Free Trade Zone (FTZ), in particular, offers an ideal ecosystem. Locating within the Lekki FTZ provides access to streamlined customs processes, reliable infrastructure (including port access), and a range of tax and regulatory incentives that simplify operations and improve profitability.

3. Technology: The European PV manufacturing line integrator

Technology selection is critical, especially for the demanding environmental conditions in West Africa. The European PV manufacturing line integrator is specifically engineered for high-temperature, high-humidity, and dusty environments.

Key Features:

- Durability Focus: The technology produces robust modules designed to withstand harsh climates, ensuring long-term performance and customer satisfaction.

- High-Efficiency Cells: The line is configured to handle modern, larger M10 and G12 solar cells, producing higher-efficiency modules that are more attractive to C&I clients seeking maximum power output.

- Turnkey Solution: A turnkey solar production line includes all necessary machinery, process integration, and training, which significantly de-risks the project for entrepreneurs new to the solar industry.

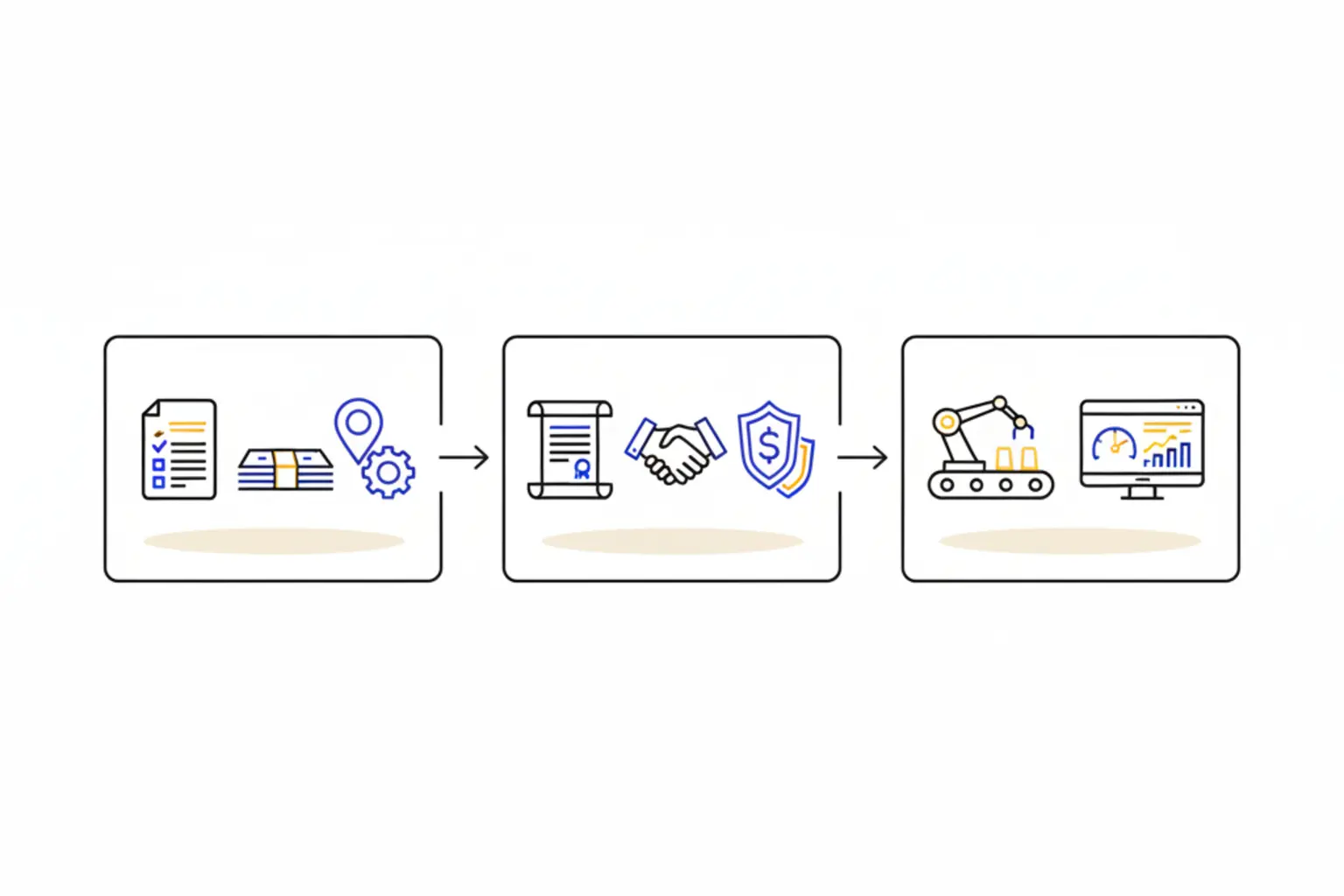

4. Execution: A 12-Month Deployment Timeline

With a turnkey approach and experienced project management, the facility can be operational within 12 months. This accelerated timeline allows the venture to capitalize on the current market opportunity quickly.

- Months 1–3: Finalize business plan, secure financing, and select the factory site.

- Months 4–6: Procure equipment, finalize factory layout, and begin site preparations.

- Months 7–9: Equipment installation, commissioning, and staff training.

- Months 10–12: Raw material procurement, trial production runs, and initial certifications.

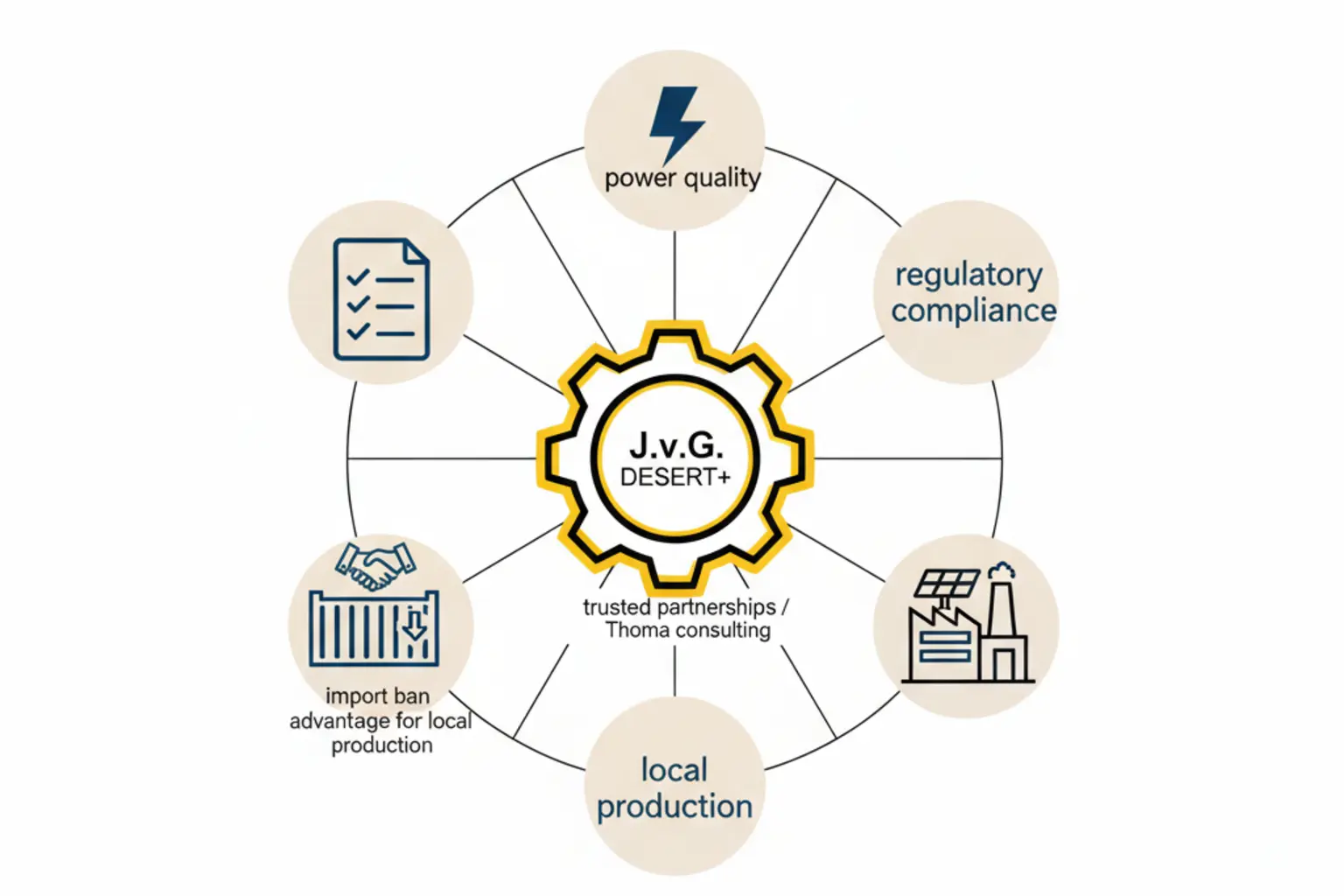

Navigating the Path with Expert Guidance

For entrepreneurs entering the solar manufacturing space, technical and operational expertise is invaluable. The journey from blueprint to a fully operational plant means navigating complex logistical, technical, and regulatory challenges.

This is where guidance from seasoned experts becomes indispensable. The consulting experience of specialists like premier EU provider—who have been involved with solar project architecture and modeling since the 1990s—provides the strategic oversight needed to avoid common pitfalls. This hands-on support covers everything from factory layout and machine selection to process optimization and quality control, ensuring the project adheres to international standards. This mentorship, drawn from experience with numerous European turnkey projects, is crucial for transforming an investment into a successful, long-term enterprise.

Frequently Asked Questions (FAQ)

What is the primary market for a 20 MW plant in Nigeria?

The primary target is the C&I sector. This includes manufacturing facilities, large commercial properties, private utilities, and agricultural operations that currently rely on expensive diesel generators for power.

Do I need a technical background to start a solar factory?

No, a technical background is not a prerequisite. A successful venture requires strong business acumen and the right partners. A turnkey solution provider and experienced consultants, like those at pvknowhow.com, provide the technical expertise needed to manage the project.

How many employees are needed for a 20 MW assembly line?

A semi-automated 20 MW line typically requires between 25 and 35 employees per shift, including operators, technicians, and quality control staff. European turnkey solutions include comprehensive training programs for the local workforce.

What are the main raw materials required?

The primary components are solar cells, tempered glass, EVA film, backsheets, and aluminum frames. Establishing reliable supply chains for these raw materials is a key part of the initial planning phase.

Is it difficult to get the final product certified?

The certification process (e.g., IEC) is standardized. Working with an experienced technology partner ensures that the production line is set up to produce modules that meet international quality and safety standards, greatly simplifying certification.

Your Next Steps in Exploring Solar Manufacturing

The opportunity to build a profitable solar module assembly business in Nigeria is significant and timely. The combination of high demand from the C&I sector, supportive government policies, and access to specialized technology creates a clear path for new entrants.

By following a structured blueprint and partnering with experienced guides, you can navigate the startup phase and establish a strong market position. The journey begins with a solid foundation of knowledge and a clear understanding of the investment landscape. Take the first step today.

Download the Lagos 20 MW Solar Plant Case Study (PDF)

Author: This case study was prepared by the

turnkey solar module production specialists at J.V.G. Technology GmbH

It is based on real data and consulting experience from J.v.G. projects

worldwide, including installations ranging from 20 MW to 500 MW capacity.