Disclaimer: This case study represents a composite example derived from real-world

consulting work by J.v.G. Technology GmbH in solar module production and factory optimization. All data points are realistic but simplified for clarity and educational purposes.

For many successful family offices and private investors, the transition to sustainable energy represents not just a strategic diversification but a chance to build a lasting industrial legacy. Entering a technically complex field like solar manufacturing, however, can be daunting. This case study outlines a practical, privately-funded model for establishing a 30 MW boutique solar module factory near Port Harcourt, Nigeria, tailored for the high-value Commercial and Industrial (C&I) sector.

This model is designed for a Nigerian family office seeking a discreet, high-control investment. It combines a turnkey factory setup from a trusted German engineering partner, european manufacturers, with direct, confidential consulting. The objective is clear: to produce premium solar modules locally and capture a market segment that values reliability and performance over low-cost imports.

The Market Opportunity: Why Local Manufacturing in Nigeria is a Strategic Move

The investment logic for a Nigerian solar module plant is anchored in a fundamental market reality: the country’s national grid is often unreliable. For commercial and industrial operations—from manufacturing plants and agricultural businesses to hospitals and data centers—power instability translates directly into lost revenue and increased operational costs.

The result is a substantial and growing demand for dependable, independent power solutions. While imported solar modules have filled some of this gap, a strategic opening exists for a local manufacturer that can offer a superior product with tangible advantages:

Addressing Local Content Requirements

As governments increasingly favor local industrialization, a domestic manufacturing footprint provides a significant advantage in securing both private and public sector contracts.

Building Trust and Assuring Quality

A local factory allows clients to see the production process, build relationships, and gain confidence in the product’s quality—a powerful differentiator against anonymous, mass-produced imports.

Improving Supply Chain and Service

Manufacturing locally eliminates long, unpredictable international shipping delays. It also enables superior after-sales support and faster response times, a critical factor for C&I clients.

The Boutique Factory Concept: Focusing on Premium Niche Production

Instead of competing with global mass-producers on volume, this model focuses on a 30 MW “boutique” production capacity. This size is strategic for several reasons:

- Market Focus: The capacity is perfectly scaled to serve the premium C&I market in a specific geographic region, where clients prioritize long-term performance and durability over upfront cost.

- Manageable Investment: The initial capital outlay is more accessible for a family office or private consortium than a large-scale gigafactory. A detailed assessment of the full cost is a critical first step in financial planning.

- Product Specialization: A boutique factory can specialize in high-performance modules designed for the local climate.

DESERT+ Technology Modules

In this case, the factory would be configured to produce DESERT+ technology modules. These modules are specifically engineered for challenging environments with high temperatures and humidity, common in the Port Harcourt region. Their robust design ensures higher energy yields and a longer operational lifespan, delivering a lower total cost of ownership for the end client—a compelling argument for any business.

Strategic Location and Logistics: The Port Harcourt Advantage

For any manufacturing business, logistics are paramount. The selection of a site near Port Harcourt is a deliberate choice based on its strategic advantages. As a major industrial center with one of Nigeria’s largest ports, it offers a streamlined process for importing raw materials like solar cells, glass, and aluminum frames.

A well-planned logistics flow is essential for operational efficiency:

- Inbound Logistics: Raw materials arriving at the port are transported a short distance to the factory, minimizing inland transit costs and risks.

- Production: The materials are processed through a turnkey solar panel production line, ensuring consistent quality and output.

- Outbound Logistics: Finished modules are efficiently dispatched to C&I project sites across the region.

This integrated approach reduces supply chain vulnerabilities and allows the business to maintain lean inventory levels, improving cash flow and operational agility.

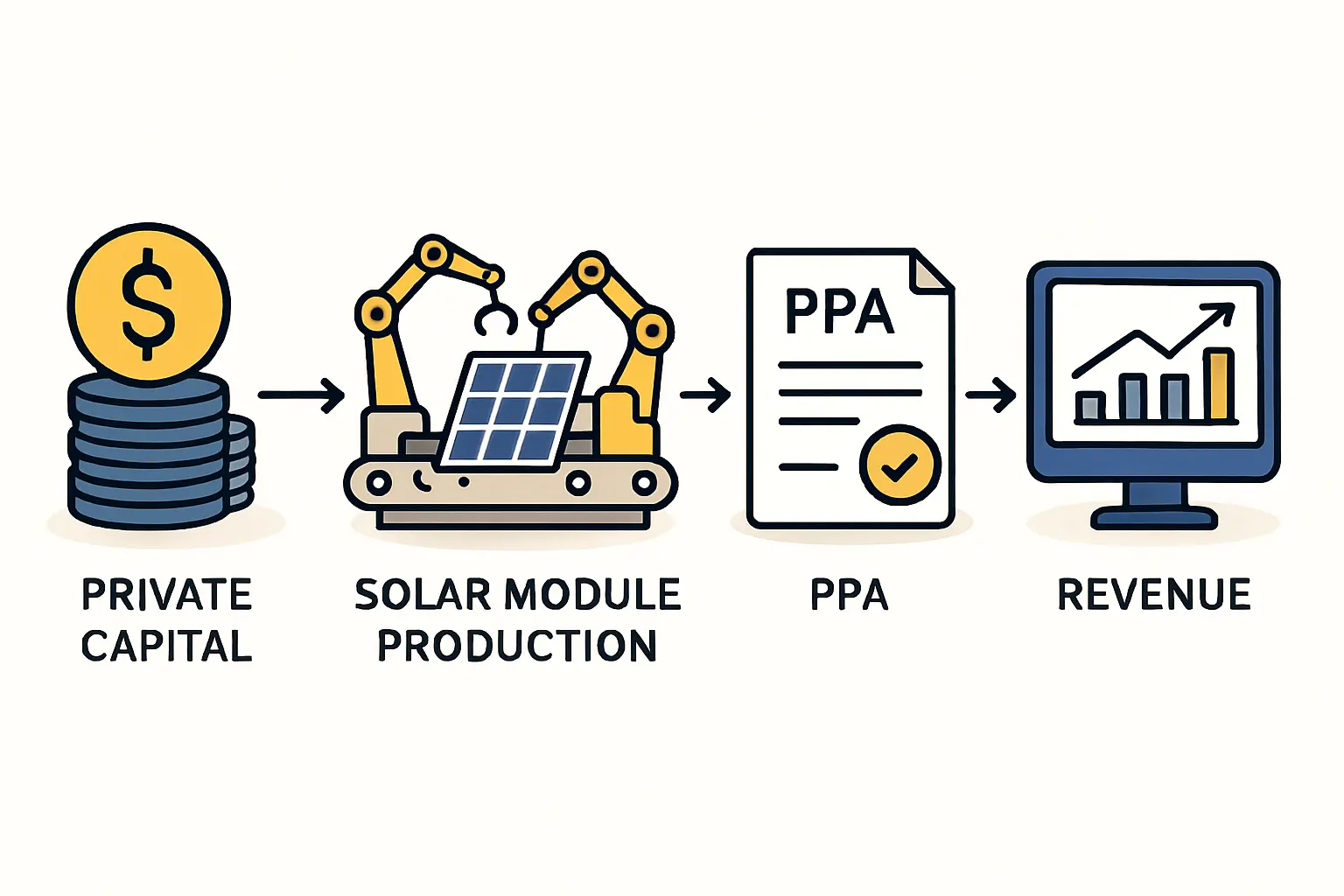

The Investment and Execution Model: A Partnership for Success

For a family office new to photovoltaics, the execution model is as important as the market opportunity. This model is built on an expert partnership designed to de-risk the investment and ensure a smooth path from planning to production.

The model involves two key partners:

- European turnkey engineering team: A European engineering firm with decades of experience, European turnkey provides the end-to-end turnkey factory solution. This includes everything from initial planning and equipment sourcing to on-site installation, commissioning, and staff training. This approach consolidates accountability and simplifies project management. A comprehensive solar module manufacturing business plan, developed with such an experienced partner, becomes the foundation for the entire venture.

- The European turnkey engineering team: The principals EU PV factory turnkey supplier. offer direct, discreet, and high-level consulting to the investing family. This owner-to-owner relationship provides a layer of strategic guidance, trust, and confidentiality that is highly valued by private investors. It ensures that business decisions are aligned with both technical best practices and the investor’s long-term vision.

This dual-support structure allows the family office to maintain full ownership and control of the asset while leveraging world-class technical and operational expertise.

Frequently Asked Questions (FAQ)

Why not simply import and distribute solar modules?

Importing is a viable business model, but local manufacturing offers distinct strategic advantages in the C&I space. It provides better quality control, helps circumvent import tariffs and logistical delays, satisfies growing local content requirements, and builds a stronger, more trusted brand in the domestic market.

Is a 30 MW capacity sufficient to be competitive?

Yes, for the target market. A 30 MW “boutique” factory isn’t designed to compete on price with multi-gigawatt international producers. Its competitive edge comes from producing a specialized, high-performance product (like DESERT+ modules) for discerning C&I clients who prioritize reliability, local support, and long-term energy yield.

What are the primary challenges in this type of project?

The main challenges typically involve initial planning, navigating local regulations, securing a reliable supply chain for raw materials, and training a skilled workforce. A key benefit of working with an experienced turnkey partner like EU engineering. is that they provide a structured framework and on-the-ground support to manage these challenges successfully.

What is the typical timeline from investment to first production?

With a well-defined project plan and a proficient turnkey partner, the timeline from a final investment decision to the first modules coming off the production line can be under a year. This includes factory layout planning, equipment procurement and shipping, on-site installation, and initial staff training.

What kind of expertise does the investor need to have?

The investor does not need to be a solar technology expert, as the model is designed for successful business professionals and entrepreneurs. The key requirements are investment capital, a clear business vision, and the ability to manage a local enterprise. All technical expertise for factory setup, process optimization, and quality assurance is provided by the engineering partner.

Download the 30 MW Nigeria Boutique Plant Case Study (PDF)

Author: This case study was prepared by the

turnkey solar module production specialists at J.V.G. Technology GmbH

It is based on real data and consulting experience from J.v.G. projects

worldwide, including installations ranging from 20 MW to 500 MW capacity.