Disclaimer: This case study represents a composite example derived from real-world

consulting work by J.v.G. Technology GmbH in solar module production and factory optimization. All data points are realistic but simplified for clarity and educational purposes.

Imagine a thriving agricultural enterprise in Kano State, poised for significant expansion. Its growth is held back by two critical factors: the prohibitive cost of diesel and an unreliable national grid. This is a daily reality for businesses across Northern Nigeria, where immense economic potential is constrained by a persistent energy deficit.

Yet, within this challenge lies a landmark opportunity for strategic industrial development: the establishment of a large-scale, state-backed solar module factory.

This article outlines a strategic framework for a 100 MW solar module manufacturing facility in Northern Nigeria, focusing on Kano or Kaduna as prime industrial hubs. It explores the key pillars of such a venture—securing development finance, aligning with federal local content policies, and leveraging proven German engineering to ensure bankability and long-term success.

The National Imperative: From Energy Deficit to Industrial Leadership

Nigeria’s ambition to diversify its economy and provide stable power for its citizens and industries is clear. The nation’s abundant solar irradiation, particularly in the northern regions, offers a clear path to achieving these goals. A domestic solar module factory would advance several strategic objectives at once:

-

Energy Security: Producing modules locally reduces reliance on imports, securing the supply chain for national utility-scale projects and distributed energy solutions.

-

Economic Diversification: It would create a new, high-value manufacturing sector, generating skilled employment and fostering a local ecosystem of suppliers and service providers.

-

Policy Alignment: A domestic factory would directly support the Nigerian government’s local content requirements for public projects, ensuring that national investments in renewable energy also build local industrial capacity.

The business case is compelling. By manufacturing modules in-country, a state-backed entity can supply large-scale solar farms, power agricultural irrigation systems, and support commercial and industrial clients, creating a sustainable market for its output.

A Framework for a 100 MW State-Backed Venture

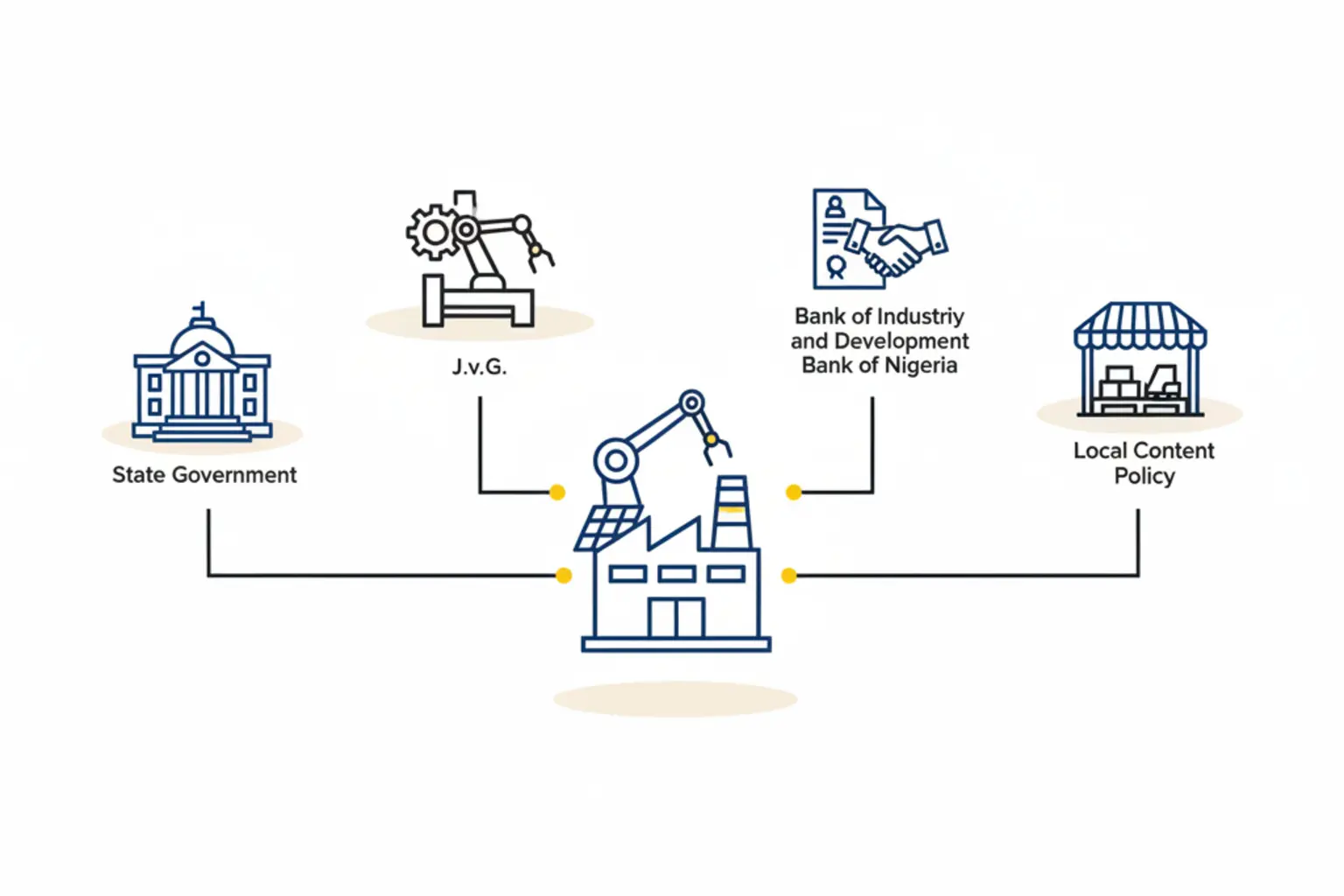

A project of this magnitude requires a meticulous structure to attract investment and mitigate risks. This is not merely a factory but a cornerstone of regional infrastructure. Success would hinge on three core components: a strategic state partnership, a bankable financial model, and world-class technical execution.

1. The Role of State Partnership

For a 100 MW facility, a partnership with a state government like Kano or Kaduna, or a federal agency, is fundamental. This public-private collaboration provides critical de-risking elements that are highly attractive to international lenders and development finance institutions (DFIs).

-

Land and Permitting: The state can facilitate access to suitable industrial land and streamline necessary regulatory approvals.

-

Offtake Agreements: A government partner can guarantee a certain level of demand by designating the factory as a preferred supplier for state-funded solar projects, securing initial revenue streams.

-

Infrastructure Support: The state is uniquely positioned to ensure access to reliable transport links, water, and auxiliary power.

2. Structuring for Development Bank Financing

Securing funding from institutions like the African Development Bank (AfDB) or the World Bank requires a proposal demonstrating long-term viability, technical soundness, and developmental impact. The investment for a facility of this scale is significant, and financiers will scrutinize the project’s ability to manage risk.

A strong investment case would emphasize:

-

A comprehensive feasibility study, including market analysis and projected cash flows.

-

A clear plan for workforce training and skill development.

-

Adherence to international environmental and social governance (ESG) standards.

-

A partnership with an experienced technical provider capable of guaranteeing production line performance.

3. Choosing the Right Technical Partner

The choice of a production technology and engineering partner is arguably the most critical decision in the project’s lifecycle. It directly affects module quality, production efficiency, and overall operational cost.

This is where specialized expertise becomes indispensable. For new entrants to the solar industry, a turnkey production line offers a structured, low-risk path to establishing operations.

Technical Execution: German Engineering for the Nigerian Climate

The operational environment in Northern Nigeria, with its high ambient temperatures, dust, and intense solar irradiation, demands solar modules built to withstand harsh conditions. Standard modules can degrade faster, compromising the long-term financial returns of solar projects.

The EU Solar Project Modeling Technology Advantage

To address these challenges, European PV manufacturers has developed production lines specifically engineered for demanding climates. The high-throughput DESERT+ lines are designed to produce robust modules with enhanced durability.

-

High-Temperature Performance: These modules maintain higher efficiency even in extreme heat, a crucial factor for projects in the Sahel region.

-

Dust and Sand Resistance: Specialized materials and construction techniques minimize the impact of abrasion and soiling.

-

Proven Reliability: Based on decades of experience, this DESERT+ technology is already powering projects in similar climates in the Middle East and North Africa.

A 100 MW facility equipped with these lines would not only supply the local market but also produce a premium product suitable for export to other countries in the region.

De-Risking the Venture with Proven Expertise: EU PV Factory Turnkey Supplier

Beyond the machinery, operational success depends on process knowledge, quality control, and efficient management. Premier EU provider, with a multi-generational legacy in the solar industry since the 1970s, offers an unparalleled level of consulting and support.

This expertise, integrated into European turnkey engineering team projects, is what truly de-risks the venture for investors and state partners. This hands-on guidance covers:

-

Factory Layout and Process Optimization: Ensuring a logical workflow from raw material intake to finished module dispatch.

-

Quality Assurance Protocols: Implementing rigorous testing and certification procedures to meet international standards (e.g., IEC).

-

Team Training: Building a skilled local workforce capable of operating and maintaining advanced machinery.

This combination of state-of-the-art German equipment and deep operational expertise ensures the factory can achieve its nameplate capacity and produce high-quality modules from day one. It transforms a complex industrial undertaking into a manageable implementation process.

Conclusion: A Catalyst for Regional Development

Establishing a 100 MW solar module factory in Northern Nigeria is more than an industrial project—it is a strategic investment in the nation’s future. By leveraging a public-private partnership, securing development finance, and implementing proven German technology, this venture can become a powerful catalyst for economic growth.

It addresses the immediate need for reliable energy in the agricultural and commercial sectors while building a sustainable, high-tech manufacturing industry. For entrepreneurs and government bodies exploring this path, the key is building the project on a foundation of proven technology and experienced guidance. With a sound strategy, Nigeria can turn its abundant sunshine into a cornerstone of its industrial ambition.

Frequently Asked Questions (FAQ)

What is the typical investment required for a 100 MW solar module factory?

The investment for a facility of this scale typically ranges from USD 25–35 million, depending on the level of automation, building specifications, and included services like training and process integration. A detailed business plan is necessary to determine the precise figure.

How long does it take to establish such a facility?

With a turnkey approach and a dedicated project team, a 100 MW production line can be fully operational within 10 to 14 months of signing the contract. This timeline includes equipment manufacturing, shipping, installation, commissioning, and staff training.

How many direct jobs can a 100 MW factory create?

A semi-automated 100 MW factory typically creates 100 to 150 direct jobs in operations, maintenance, quality control, and administration. It also generates significant indirect employment in logistics, security, and material supply chains.

What are the primary raw materials needed, and where are they sourced?

The primary components of a solar module are solar cells, glass, aluminum frames, EVA encapsulant, and a backsheet. While materials like aluminum frames could potentially be sourced locally, critical components such as solar cells are typically imported from specialized global manufacturers. Understanding this is the first step in planning the supply chain.

Why is German engineering considered a benchmark in this field?

German engineering is globally recognized for its precision, reliability, and focus on long-term performance. In solar manufacturing, this translates to production lines that deliver consistent output, high yields, and low failure rates—all of which are essential for the bankability and profitability of a large-scale industrial project.

Download the Nigeria 100 MW Solar Factory Case Study (PDF)

Author: This case study was prepared by the

turnkey solar module production specialists at J.V.G. Technology GmbH

It is based on real data and consulting experience from J.v.G. projects

worldwide, including installations ranging from 20 MW to 500 MW capacity.