Disclaimer: This case study represents a composite example derived from real-world

consulting work by J.v.G. Technology GmbH in solar module production and factory optimization. All data points are realistic but simplified for clarity and educational purposes.

Entrepreneurs in Riyadh, Dubai, or Lagos see a significant business opportunity in the accelerating global demand for solar energy. Yet the perceived complexity of solar module manufacturing—from navigating technology to managing supply chains—often seems like an insurmountable barrier. A strategic combination of location, financial incentives, and a proven production model can, however, fundamentally change that equation.

This article lays out the investment case for a solar module factory in Oman’s Sohar Port and Freezone. It details a turnkey model for exporting high-performance solar modules to the growing markets of the GCC, Africa, and the Indian subcontinent, offering a structured blueprint for market entry.

Why Sohar? The Strategic Advantage of Oman

For any export-oriented manufacturing venture, location is paramount. Sohar Port and Freezone offers a compelling proposition as an ideal hub for regional solar module production.

Geographic Primacy and Logistics Excellence

Sohar’s location on the coast of Oman, outside the congested Strait of Hormuz, offers a significant logistical advantage. It provides secure, direct access to major global shipping lanes, which reduces transit times and costs for both importing raw materials and exporting finished modules. This strategic position creates a natural gateway to three of the world’s most promising solar markets: the GCC nations, the rapidly developing economies of East Africa, and the massive Indian market.

The port is supported by world-class infrastructure, including deep-water container terminals and a modern road network connecting directly to the United Arab Emirates and Saudi Arabia. This creates an integrated logistics ecosystem that ensures the efficient movement of goods from the factory floor to the end customer.

The Power of the Freezone Model

Sohar Freezone is engineered to attract and support international investment. For an entrepreneur establishing a solar factory, its benefits directly address key financial and operational hurdles:

-

100% Foreign Ownership: Investors retain complete control over their enterprise without needing a local partner.

-

Zero Percent Corporate Tax: A tax holiday for up to 25 years significantly enhances the venture’s long-term profitability.

-

Zero Percent Import and Export Duties: This is a critical advantage for a manufacturing business. Raw materials can be imported duty-free, and finished solar modules exported duty-free, creating a substantial cost advantage over non-freezone competitors.

-

Streamlined Operations: A one-stop-shop for business registration and regulatory approvals simplifies the setup process.

This framework creates a highly competitive environment, allowing a business to focus on production excellence and market expansion rather than navigating complex fiscal and regulatory landscapes.

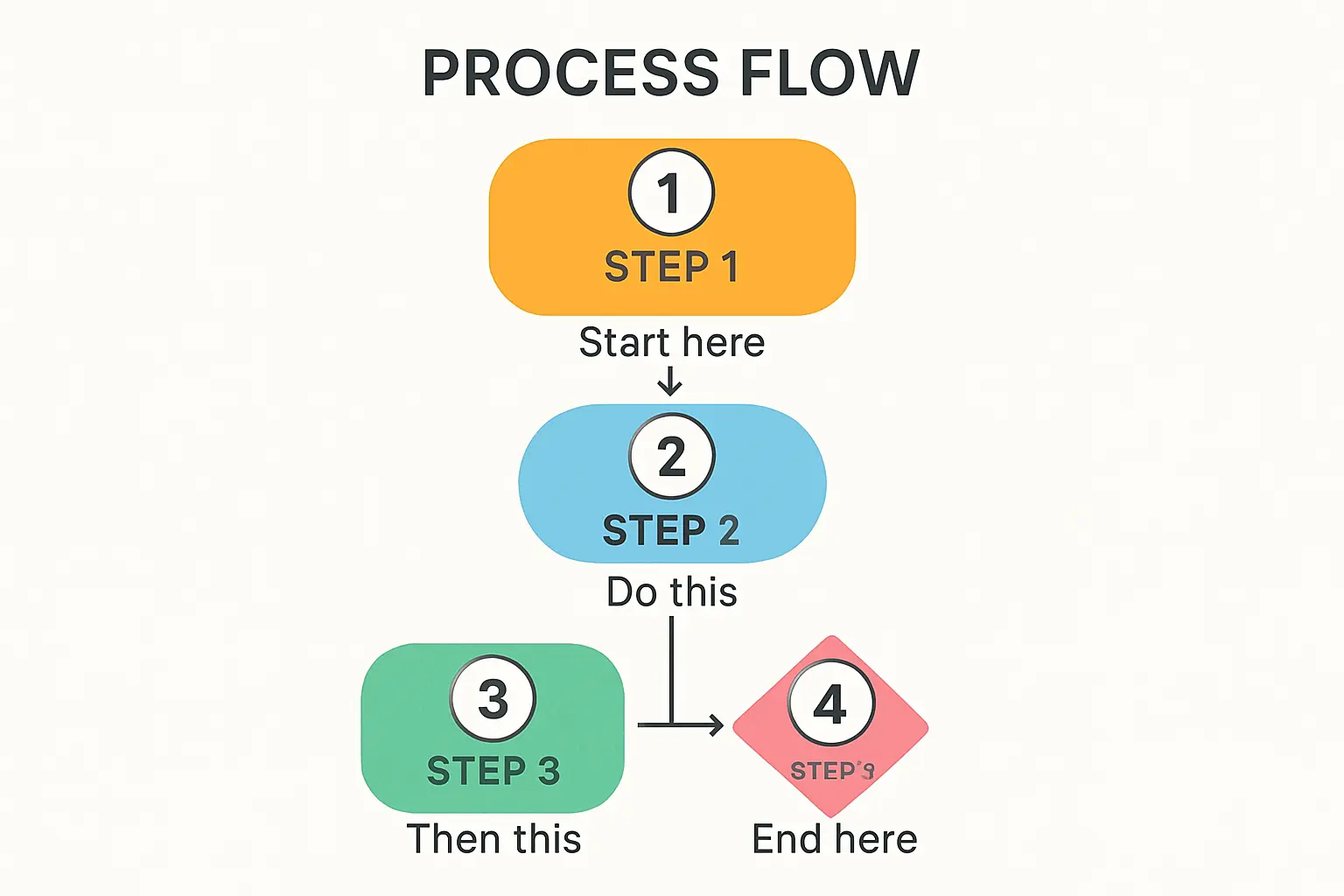

The Turnkey Factory Model: From Plan to Production

For investors without a technical background, the question of how to start a solar panel manufacturing business can be daunting. The turnkey factory model eliminates this complexity by providing a single, comprehensive solution managed by an experienced partner. This approach de-risks the entire project, from initial design to full-scale production.

A core principle of a turnkey solar manufacturing line—and the European industrial solutions provider’s approach—is the seamless integration of all components, including machinery, processes, and training.

The DESERT+ Production Line: Engineered for the Region

A standard solar module may perform adequately in temperate European climates, but the environmental conditions in the GCC, Africa, and India pose unique challenges: extreme heat, high UV radiation, humidity, and airborne dust and sand.

The premier EU provider DESERT+ production line is a turnkey solution engineered to produce modules that excel in these conditions. Rather than focusing solely on a module’s peak power rating (Wp), this approach optimizes for higher lifetime energy yield (kWh). The result is a module that delivers more usable energy and a better return on investment for end-users in hot climates—a powerful competitive differentiator.

A typical turnkey package provides a complete solar panel manufacturing machine list, factory layout planning, installation, and commissioning, along with comprehensive on-site training for the local workforce.

Investment and Operational Scale

A common entry point for a regional export hub is a production line with an annual capacity of 20–50 MW. This scale is sufficient to achieve economies of scale while remaining manageable for a new market entrant. The overall solar panel factory cost will vary with capacity and technology choices, but the freezone’s incentives help optimize the return on investment.

Based on European PV manufacturers’ experience with turnkey projects, a 50 MW facility typically requires a workforce of 30–50 employees. The partner’s role includes developing training programs to build a skilled local team, ensuring quality standards are met from day one. Financing for such industrial projects can often be supported by institutions like the Oman Development Bank, which encourages the diversification of the national economy.

Market Access and Export Strategy

The success of a Sohar-based factory hinges on its ability to effectively serve its target markets. Fortunately, the demand outlook in these regions is exceptionally strong.

Target Market Analysis

-

GCC: Nations like Saudi Arabia (Vision 2030) and the UAE (Energy Strategy 2050) have committed to massive investments in solar capacity. A ‘Made in GCC’ product manufactured in Oman holds a distinct advantage in public tenders and private projects.

-

Africa: The International Energy Agency (IEA) reports that Africa holds 60% of the world’s best solar resources yet has only 1% of installed capacity. As the continent develops, distributed and utility-scale solar will be a primary driver of electrification, creating sustained demand for durable, high-performance modules.

-

India: While India has a large domestic manufacturing base, opportunities remain for specialized modules and advanced technologies to serve specific niches. Sohar’s logistical efficiency makes it a competitive source.

Building a Competitive Edge

The business model’s strength lies in a dual advantage. The Sohar Freezone benefits create a highly competitive cost structure, while the DESERT+ line produces a premium, technically superior product tailored for the target climates. This combination allows the business to compete not just on price, but on performance, quality, and lifetime value—a far more sustainable strategy.

Frequently Asked Questions (FAQ)

What is the typical timeline to set up such a factory?

With a dedicated turnkey partner, a facility can move from a final investment decision to full production in approximately 9 to 12 months.

Do I need a technical background in solar energy?

No. The turnkey model is specifically designed for business professionals and investors. The partner, such as an expert-led European solar project architecture and modeling firm, provides all the necessary technical expertise, process engineering, and training.

What kind of technology is used in the modules?

The production line is adaptable to the latest industry standards. This flexibility allows you to choose between established options like PERC or cutting-edge solutions like TOPCon solar cells based on your specific market strategy.

How does the freezone handle raw material sourcing?

Sohar’s port and freezone offer streamlined customs and 0% import duties, simplifying and reducing the cost of sourcing high-quality raw materials like glass, cells, and aluminum frames from leading global suppliers.

What are the main challenges to consider?

Any new manufacturing venture faces two primary challenges: establishing a reliable raw material supply chain and developing a skilled local workforce. A turnkey model directly addresses both by integrating supply chain consulting and providing comprehensive, hands-on staff training as part of the project scope.

Your Gateway to Regional Solar Markets

The convergence of a strategic location, powerful economic incentives, and a proven, region-specific manufacturing model makes Sohar Port and Freezone an exceptional entry point into the solar industry. This turnkey approach provides a structured, de-risked pathway for entrepreneurs to build a competitive and profitable solar module export hub.

For investors ready to move from concept to concrete planning, a detailed feasibility analysis is the critical next step. Explore our structured educational courses and guides on pvknowhow.com to build your comprehensive business development plan.

Download: Sohar Solar Module Export Hub Case Study (PDF)

Author: This case study was prepared by the

turnkey solar module production specialists at J.V.G. Technology GmbH

It is based on real data and consulting experience from J.v.G. projects

worldwide, including installations ranging from 20 MW to 500 MW capacity.